Cardanol modified amine epoxy resin curing agent as well as preparation method and application thereof

A technology for amine epoxy resin and resin curing, which is applied in the field of cardanol-modified amine epoxy resin curing agent and its preparation, and can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

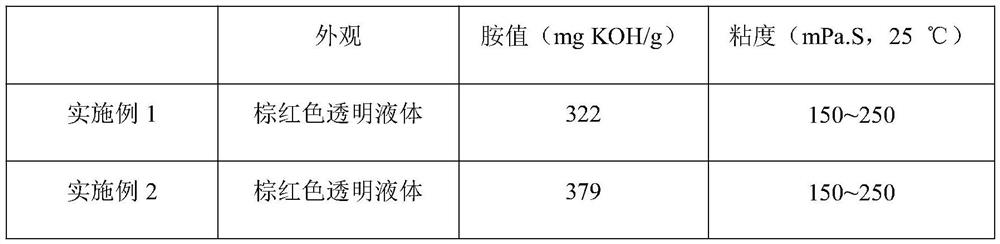

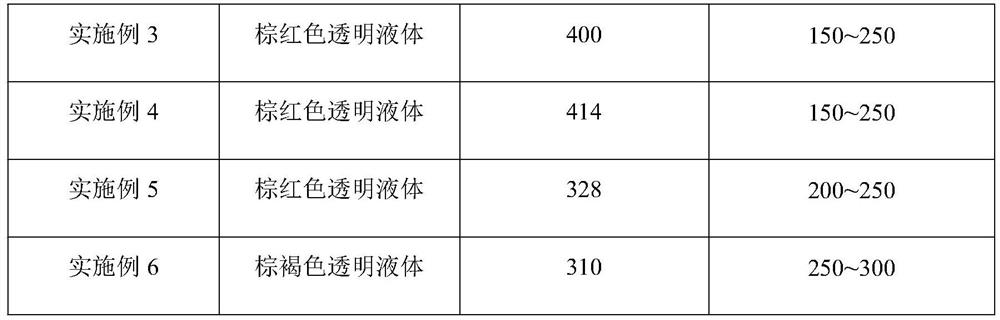

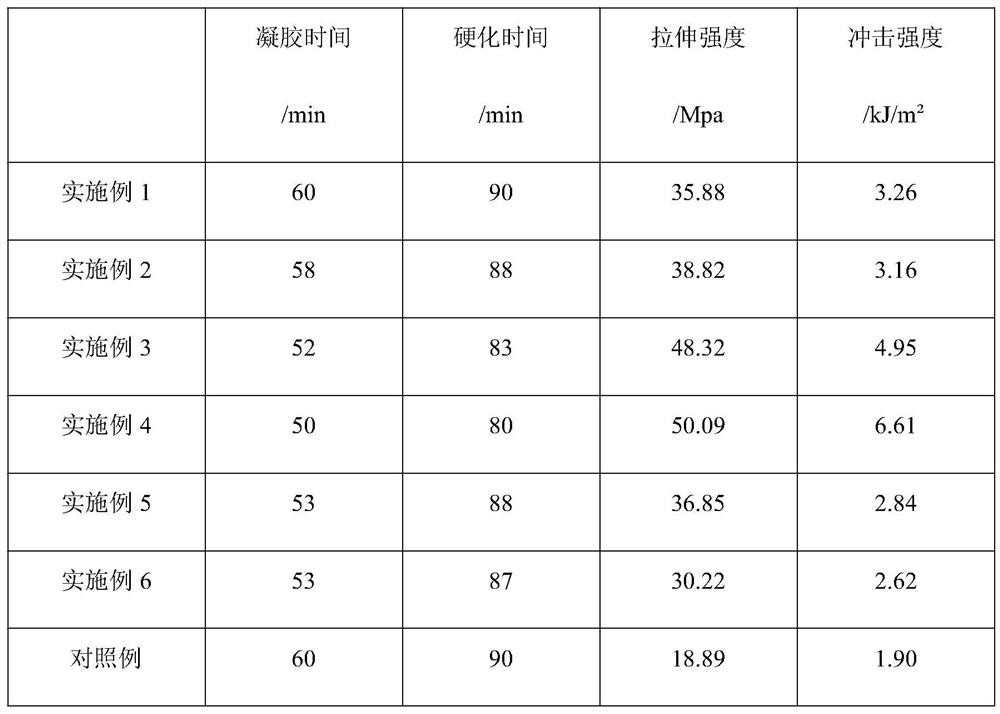

Examples

Embodiment 1

[0027] 1. Add 30g of cardanol and 25g of cardanol into a round bottom flask, start stirring, raise the temperature to 40°C, add 4g of sodium hydroxide particles; after the dissolution is complete, raise the temperature to 60°C, slowly add 0.56g of chloroacetic acid catalyst, acid catalyst After dissolving, raise the temperature to 90°C, keep it warm for 2 hours, let it stand still, separate the liquid and evacuate to obtain the intermediate product;

[0028] 2. Raise the temperature of the intermediate product obtained in step 2 to 40°C, start stirring, control the temperature not higher than 50°C, slowly add 35g of formaldehyde solution dropwise (after 20 minutes), then slowly add 51.5g of diethylenetriamine, and raise the temperature to 120°C , keep it warm for 30 minutes, then raise the temperature to 140°C, keep it warm for 30 minutes, then raise the temperature to 170°C, keep it warm for 50 minutes, then cool down to 90°C after the reaction is over, decompress and vacuum d...

Embodiment 2

[0030] 1. Add 30g of cardanol and 25g of cardanol into a round bottom flask, start stirring, raise the temperature to 40°C, add 4g of sodium hydroxide particles; after the dissolution is complete, raise the temperature to 60°C, slowly add 0.56g of chloroacetic acid catalyst, acid catalyst After dissolving, raise the temperature to 90°C, keep it warm for 2 hours, let it stand still, separate the liquid and evacuate to obtain the intermediate product;

[0031] 2. Raise the temperature of the intermediate product obtained in step 2 to 40°C, start stirring, control the temperature not higher than 50°C, slowly add 35g of formaldehyde solution dropwise (after 20 minutes), then slowly add 59.8g of triethylenetetramine, and raise the temperature to 120°C , keep it warm for 30 minutes, then raise the temperature to 140°C, keep it warm for 30 minutes, then raise the temperature to 170°C, keep it warm for 50 minutes, then cool down to 90°C after the reaction, and depressurize and vacuum d...

Embodiment 3

[0033] 1. Add 30g of cardanol and 25g of cardanol into a round bottom flask, start stirring, raise the temperature to 40°C, add 4g of sodium hydroxide particles; after the dissolution is complete, raise the temperature to 60°C, slowly add 0.56g of chloroacetic acid catalyst, acid catalyst After dissolving, raise the temperature to 90°C, keep it warm for 2 hours, let it stand still, separate the liquid and evacuate to obtain the intermediate product;

[0034] 2. Raise the temperature of the intermediate product obtained in step 2 to 40°C, start stirring, control the temperature not higher than 50°C, slowly add 35g of formaldehyde solution dropwise (20min to finish), then slowly add 36.0g of diethylenetriamine and 27.2g of triethylene Tetramine, heat up to 120°C, keep warm for 30 minutes, then heat up to 140°C, keep warm for 30 minutes, then heat up to 170°C, keep warm for 50 minutes, cool down to 90°C after the reaction, and depressurize and vacuum dehydrate at this temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com