Hat box, environmentally-friendly water-based adhesive and preparation method of environmentally-friendly adhesive

A water-based adhesive and environmentally friendly technology, applied in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problem of high volatile organic compound content, achieve good mechanical properties, low VOC content, and low VOC content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

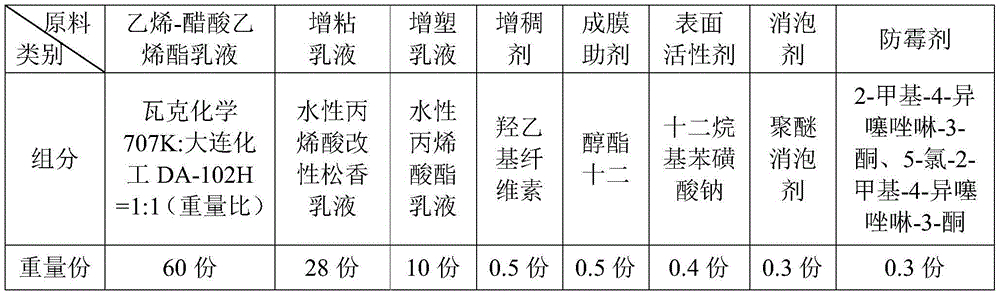

[0036] The environment-friendly water-based adhesive of this embodiment, its raw material composition and weight ratio, see Table 1 for details:

[0037] The raw material composition and the weight proportion of the environment-friendly water-based adhesive of table 1 embodiment 1

[0038]

[0039] The preparation method of the environment-friendly water-based adhesive of the present embodiment may further comprise the steps:

[0040] (1) Add 60 parts by weight of ethylene-vinyl acetate emulsion, 28 parts by weight of water-based acrylic modified rosin emulsion and 10 parts by weight of water-based acrylic ester emulsion into the kneader, at a constant temperature of 40 ° C and a vacuum of -0.02 Under the condition of MPa and the internal speed of the kneader being 50r / min, stir for 30min to obtain a blended modified emulsion;

[0041](2) 0.5 parts by weight of hydroxyethyl cellulose, 0.5 parts by weight of alcohol ester dodecyl, 0.4 parts by weight of sodium dodecylbenzen...

Embodiment 2

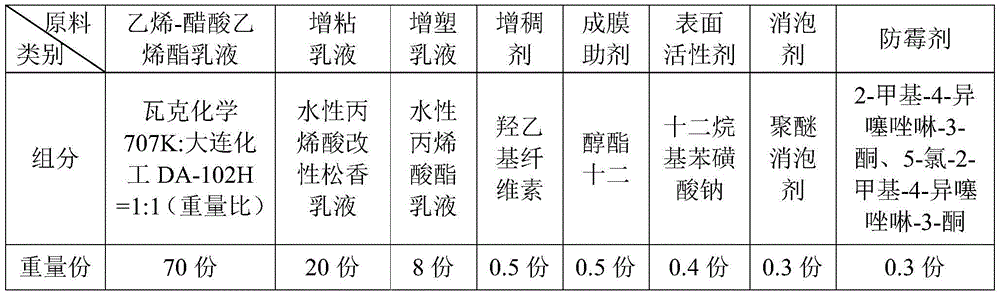

[0045] The environment-friendly water-based adhesive of this embodiment, its raw material composition and weight ratio, see Table 2 for details:

[0046] The raw material composition and the weight proportion of the environment-friendly water-based adhesive of table 2 embodiment 2

[0047]

[0048] The preparation method of the environment-friendly water-based adhesive of the present embodiment may further comprise the steps:

[0049] (1) Add 70 parts by weight of ethylene-vinyl acetate emulsion, 20 parts by weight of water-based acrylic modified rosin emulsion and 8 parts by weight of water-based acrylic ester emulsion into the kneader, at a constant temperature of 50 ° C and a vacuum of -0.05 Under the condition of MPa and the internal speed of the kneader being 60r / min, stir for 40min to obtain a blended modified emulsion;

[0050] (2) 0.5 parts by weight of hydroxyethyl cellulose, 0.5 parts by weight of alcohol ester dodecyl, 0.4 parts by weight of sodium dodecylbenzen...

Embodiment 3

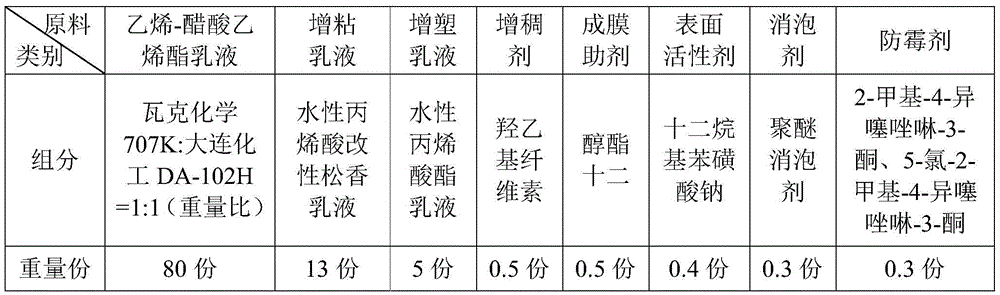

[0054] The environment-friendly water-based adhesive of this embodiment, its raw material composition and weight ratio, see Table 3 for details:

[0055] The raw material composition and the weight proportion of the environment-friendly water-based adhesive of table 3 embodiment 3

[0056]

[0057] The preparation method of the environment-friendly water-based adhesive of the present embodiment may further comprise the steps:

[0058] (1) Add 80 parts by weight of ethylene-vinyl acetate emulsion, 28 parts by weight of water-based acrylic modified rosin emulsion and 10 parts by weight of water-based acrylic ester emulsion into the kneader, at a constant temperature of 55 ° C and a vacuum of -0.08 Under the condition of MPa and the internal speed of the kneader being 70r / min, stir for 50min to obtain a blended modified emulsion;

[0059] (2) 0.5 parts by weight of hydroxyethyl cellulose, 0.5 parts by weight of alcohol ester dodecyl, 0.4 parts by weight of sodium dodecylbenze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com