Special flat dragging tape for plastic-wrapping carbon fiber elevator

A carbon fiber and flat belt technology, applied in the field of elevators, can solve the problems that the diameter of the traction sheave cannot be smaller than a certain range, the weight and the cost increase, and achieve the effects of light weight, good durability and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

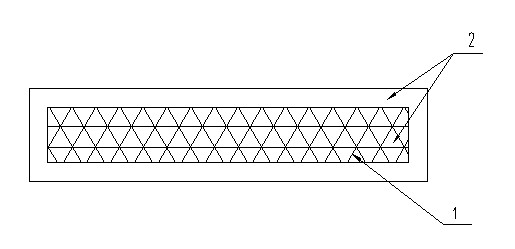

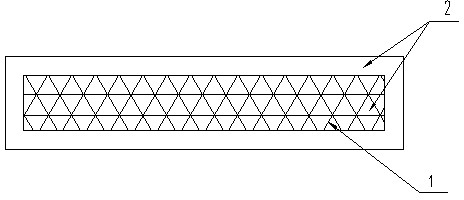

[0009] The flat traction belt for plastic-wrapped carbon fiber elevators uses multiple strands of carbon fiber ropes to be woven into a meshed carbon fiber flat belt 1, and then synthetic plastic 2 is injection molded with the carbon fiber flat belt. The carbon fiber flat belt is wrapped in the middle of the synthetic plastic. The solid synthetic plastic in the mesh of the carbon fiber flat belt forms a whole with the synthetic plastic wrapped on, under and on both sides of the carbon fiber flat belt, and the thickness of the synthetic plastic wrapped on, under and on both sides of the carbon fiber flat belt is equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com