Acrylic fiber and viscose (cotton) fiber apposition dyeing method

A one-bath dyeing and viscose technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of long production cycle, long time, unstable product quality, etc., shorten the production process, improve product performance, reduce The effect of pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

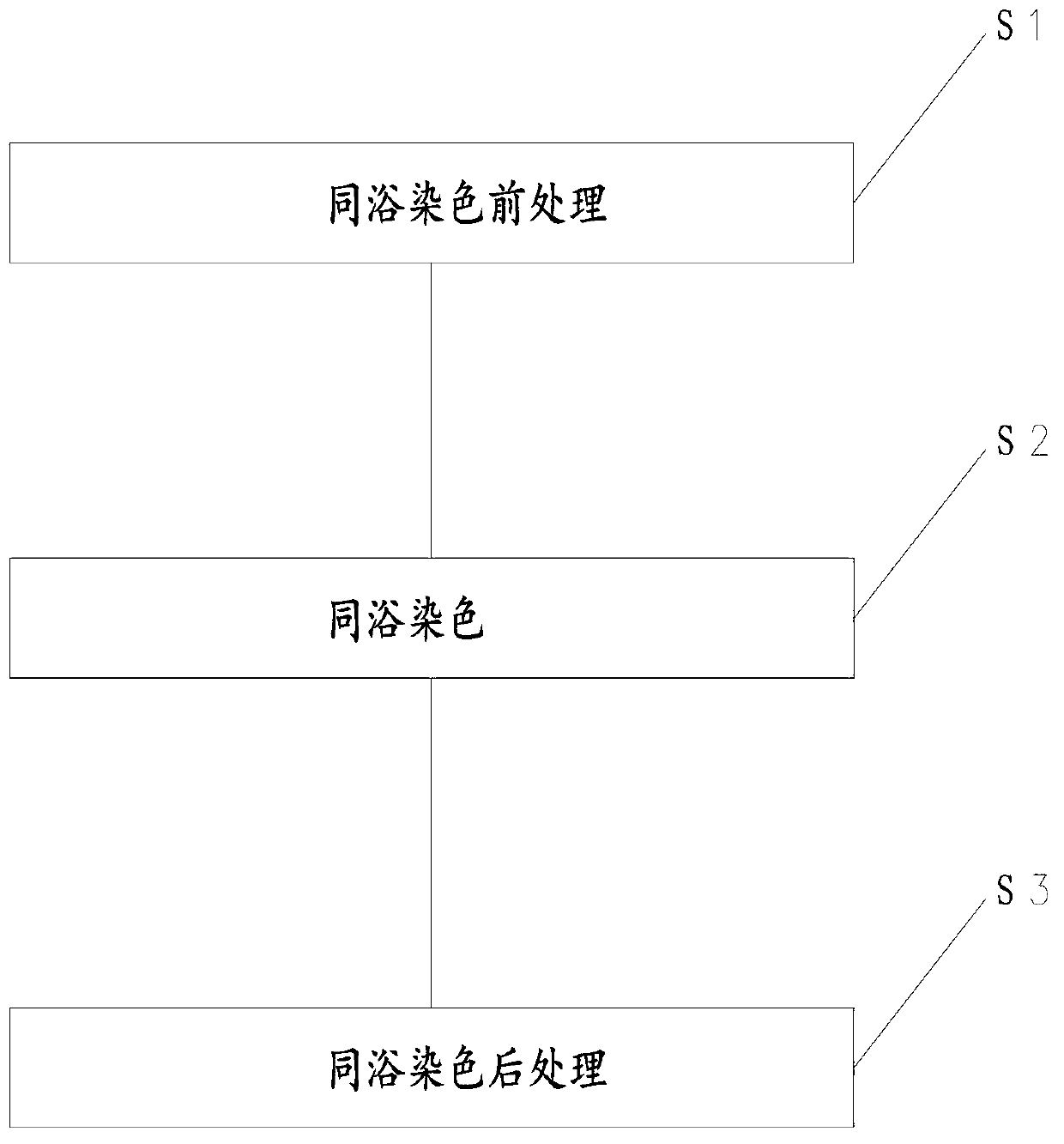

[0053] The same bath dyeing method of acrylic fiber and viscose (cotton) fiber, comprises the following steps,

[0054] (1) Before dyeing in the same bath:

[0055] Acrylic and viscose (cotton) fiber blended yarns are woven into knitted fabrics in a weight ratio of 1:1; marked as A50 / R(C)50.

[0056] (2) Dyeing in the same bath:

[0057]Put the knitted fabric mentioned in step (1) into the overflow dyeing machine, add water, then sequentially add chelating agent 8108 and pH regulator AC-608, then heat up to 30°C, add cationic dye after 10 minutes of operation, and add after 20 minutes of operation For reactive dyes, after running for 20 minutes, add sodium sulfate. After running for 20 minutes, heat up to 95°C at a rate of 1.5°C / min. After running for 50 minutes, enter the exchanger to cool down. After cooling down to 40°C, drain the water, and add heat at 50°C. Wash with water for 20 minutes to obtain knitted fabric after dyeing;

[0058] (3) After dyeing in the same bath:...

Embodiment 2

[0071] The same bath dyeing method of acrylic fiber and viscose (cotton) fiber, comprises the following steps,

[0072] (1) Before dyeing in the same bath:

[0073] Acrylic and viscose (cotton) fiber blended yarns are woven into knitted fabrics in a weight ratio of 1:1; marked as A50 / R(C)50.

[0074] (2) Dyeing in the same bath:

[0075] Put the knitted fabric mentioned in step (1) into the overflow dyeing machine, add water, then sequentially add chelating agent 8108 and pH regulator AC-608, then heat up to 40°C, add cationic dye after 8 minutes of operation, and add after 15 minutes of operation Reactive dyes, after running for 15 minutes, add Yuanming powder, after running for 15 minutes, heat up to 96°C at a speed of 1.3°C / min, after running for 40 minutes, enter the exchanger to cool down, drain the water after cooling down to 50°C, and then add heat at 60°C Wash with water for 15 minutes to obtain knitted fabric after dyeing;

[0076] (3) After dyeing in the same bath...

Embodiment 3

[0089] The same bath dyeing method of acrylic fiber and viscose (cotton) fiber, comprises the following steps,

[0090] (1) Before dyeing in the same bath:

[0091] Acrylic and viscose (cotton) fiber blended yarns are woven into knitted fabrics in a weight ratio of 1:1; marked as A50 / R(C)50.

[0092] (2) Dyeing in the same bath:

[0093] Put the knitted fabric mentioned in step (1) into the rope overflow dyeing machine, add water, then sequentially add chelating agent 8108 and pH regulator AC-608, then heat up to 50°C, run for 5 minutes, add cationic dyes, and run for 10 minutes Finally, add reactive dyes, add Yuanming powder after running for 10 minutes, heat up to 98°C at a speed of 1.5°C / min after running for 10 minutes, enter the exchanger to cool down after running for 30 minutes, drain the water after cooling down to 60°C, and then add 70°C Wash in hot water for 10 minutes to obtain knitted fabric after dyeing;

[0094] (3) After dyeing in the same bath:

[0095] Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com