Polyester glass fiber geotextile and production method thereof

A technology of polyester glass fiber and glass fiber, which is applied in the direction of non-woven fabrics, road construction reinforcements, textiles and papermaking, etc., can solve the problems of non-compliance with environmental protection and water conservation, large equipment land area, and low production efficiency, and achieve Significant waterproof effect, small equipment investment and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

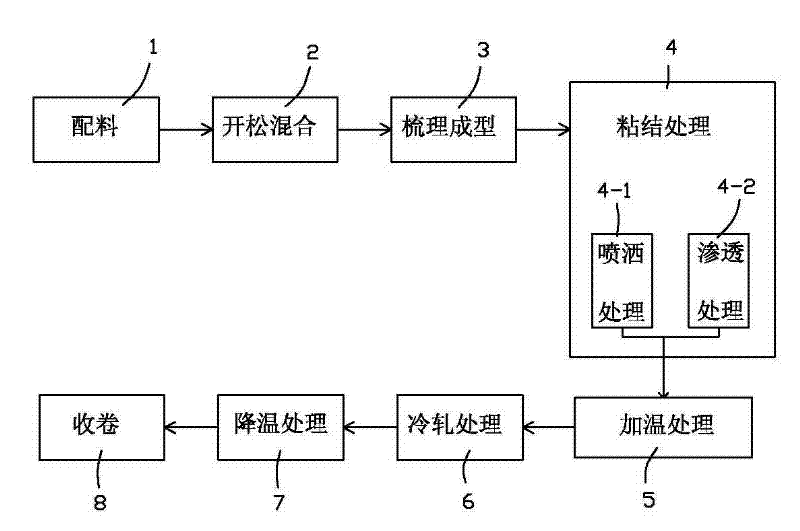

Method used

Image

Examples

Embodiment 1

[0024] A polyester fiberglass geotextile, the polyester fiberglass geotextile is formed by uniformly mixing glass fibers and polyester fibers and bonding and pressing them through a binder, the glass fibers, polyester fibers and binder The ratio of parts by weight is 5-7:2.5-4:0.5-1; wherein, the fineness of the glass fiber is 11-13 microns and the length is 50 mm; the fineness of the polyester fiber is 4D (D is denier Neil, used to indicate the fineness of the yarn, equivalent to 9000 meters / 4 grams), the length is 65-70 mm.

Embodiment 2

[0026] This embodiment is several optimizations on the basis of embodiment 1. For the same part as embodiment 1 in this embodiment, please refer to the content disclosed in embodiment 1 for understanding. The content disclosed in embodiment 1 should also be used as this The content of the embodiment will not be described repeatedly here.

[0027] Several optimal ratios of glass fiber, polyester fiber and binder in parts by weight in this embodiment are 5:4:0.5; 7:2.5:1 and 5.7:3.5:0.8, respectively.

Embodiment 3

[0029] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. The content of the example will not be repeated here.

[0030] In this embodiment, the binder is polyester powder, which is a polyester powder binder produced in Japan "Kao powder". The polyester powder index is: the softening point is 120 degrees Celsius, and the melting point is 260 degrees Celsius. In order to increase the penetration ability of the binder powder, the binder powder is combined according to different particle sizes, so that the binder is evenly distributed in the glass fiber and polyester fiber, and the breaking strength of each point of the polyester fiberglass geotextile is improved. and elongation at break consistency. The combination of the different particles of the binde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com