Hemp composite filter material and its preparation method

A compound filtration and hemp technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as increased use costs, damage to filter media, and unsatisfactory filtration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

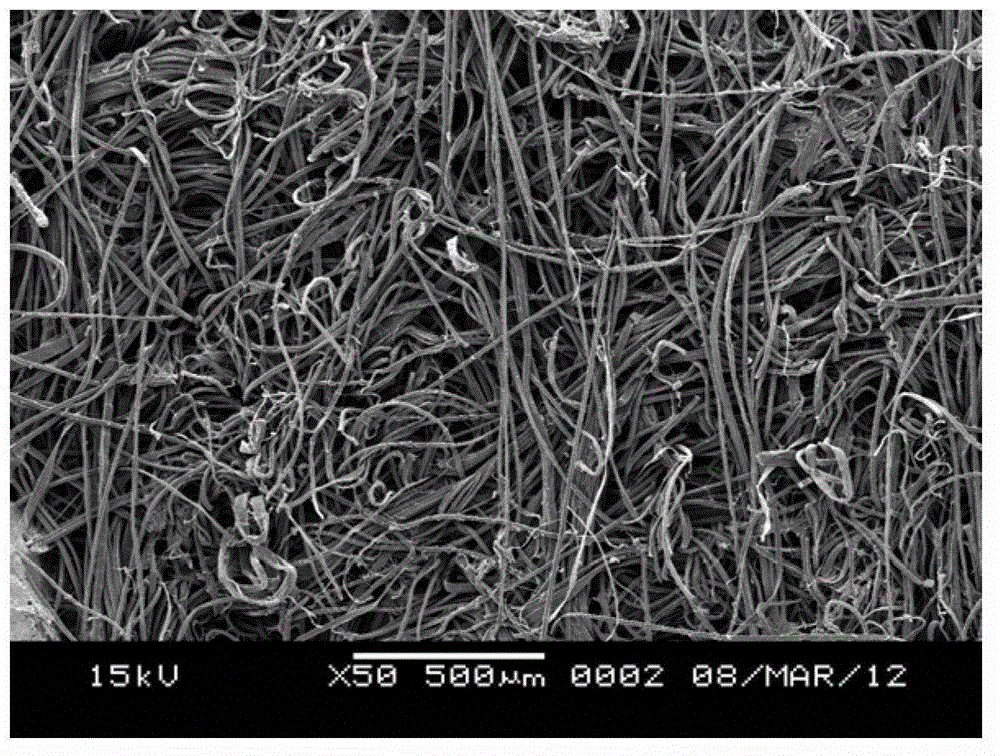

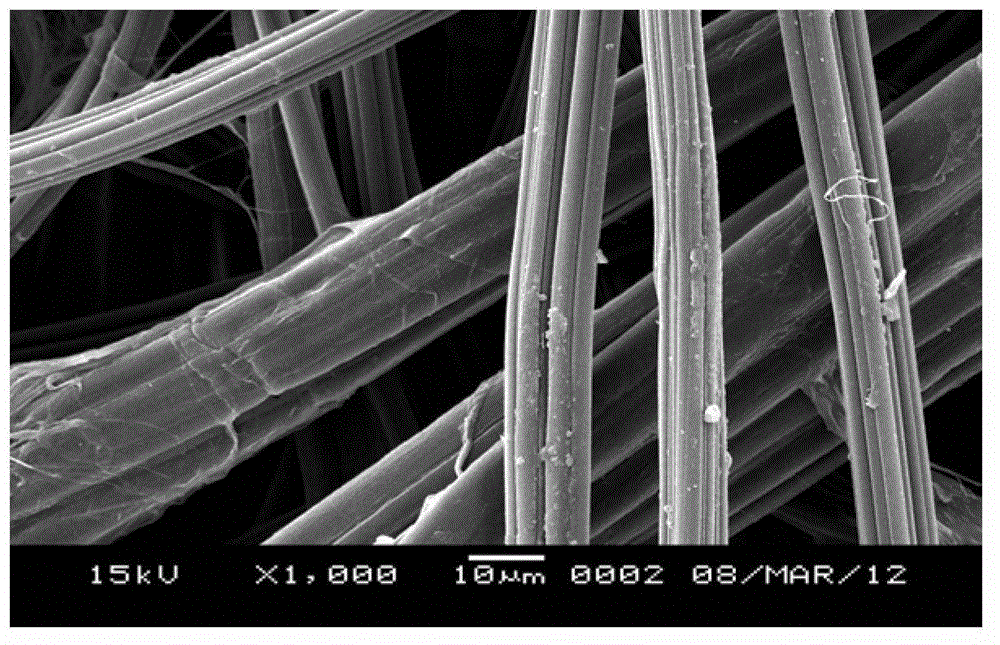

[0036] Embodiment 1, preparation hemp fiber composite filter material

[0037] (1) Preparation before weaving: hemp fiber and viscose fiber are selected. The density is 14.75μm, the hemp fiber is 6KG, and the viscose is 4KG when the sample is produced, so the blending ratio is 3:2, and the initial weight is scheduled to be 150g / m 2 .

[0038] (2) Opening and cleaning: Firstly, the hemp fiber and viscose fiber are manually opened, and the bag-shaped fiber bags in the hemp fiber and viscose fiber are torn apart by hand, and the tearing is as uniform as possible and done. Do not damage the fiber; because the color of the hemp fiber is light yellow, it is found that there are few impurities in it, basically no, and the feel is relatively soft, while the viscose fiber has more impurities. In the process of manual opening, it is found that there are branches, leaves, Impurities such as cottonseed, broken seeds, fiber seed scraps and metal products need to be removed in time to ens...

Embodiment 2

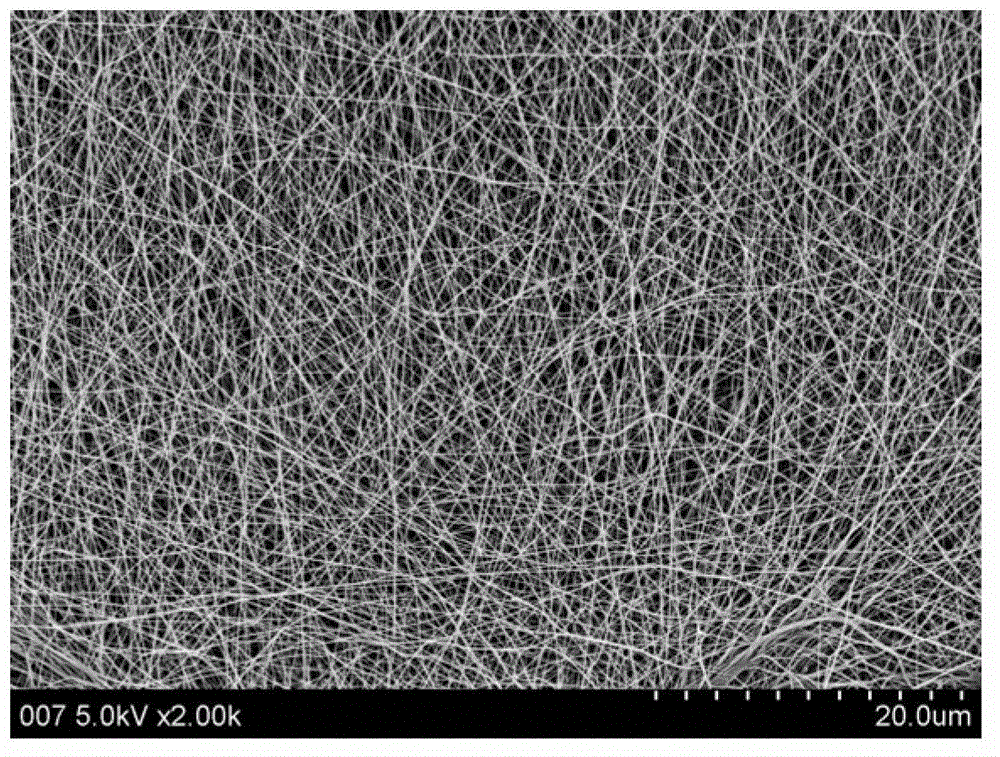

[0083] Embodiment 2, preparation hemp fiber composite filter material

[0084] (1) In the step of preparing the hemp / viscose spunlace nonwoven fabric, the preparation process is the same as that in Example 1, except that the average length of the viscose fiber is 34.06 mm, and the fineness is 11.645 μm; The average length of the hemp fiber is 90 mm, and the fineness is 3.35 μm; the mass ratio of the hemp fiber to the viscose fiber is 4:1; the drafting step is carried out in 3 drafting zones, each drafting zone The drafting ratio of each is 2; in the spunlace step, two spunlace processes are used, wherein, in the first spunlace process, the pressure of the first spunlace head is 10 bar, and the pressure of the second spunlace head is 65bar; in the second spunlace process, the pressure of the first spunlace head is 20bar, and the pressure of the second spunlace head is 80bar.

[0085] The properties of the prepared hemp / viscose spunlace nonwoven fabric are as follows in Table 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com