Continuous preparation method of activated carbon fiber cloth with high breaking strength and elongation at break

A technology of activated carbon fiber cloth and elongation at break, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., and can solve the problems of poor breaking strength and elongation at break of activated carbon fiber cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

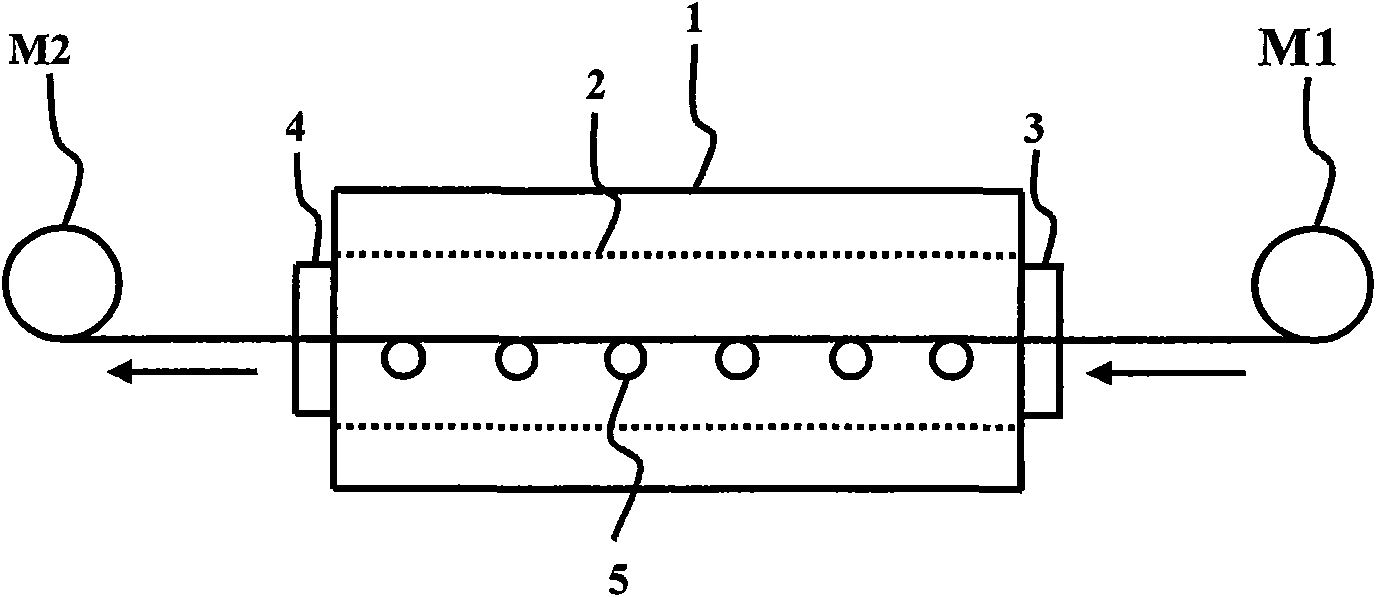

Method used

Image

Examples

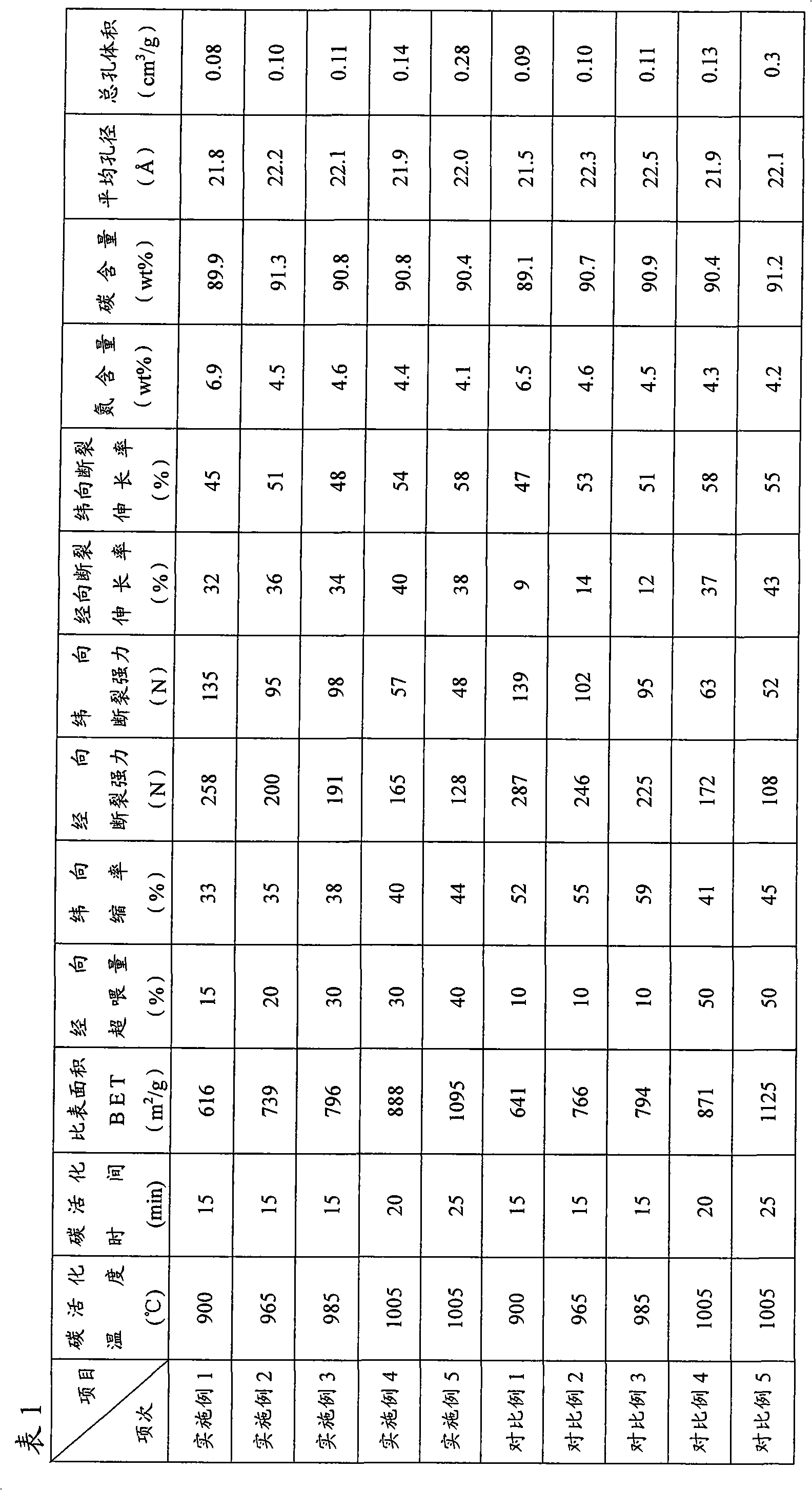

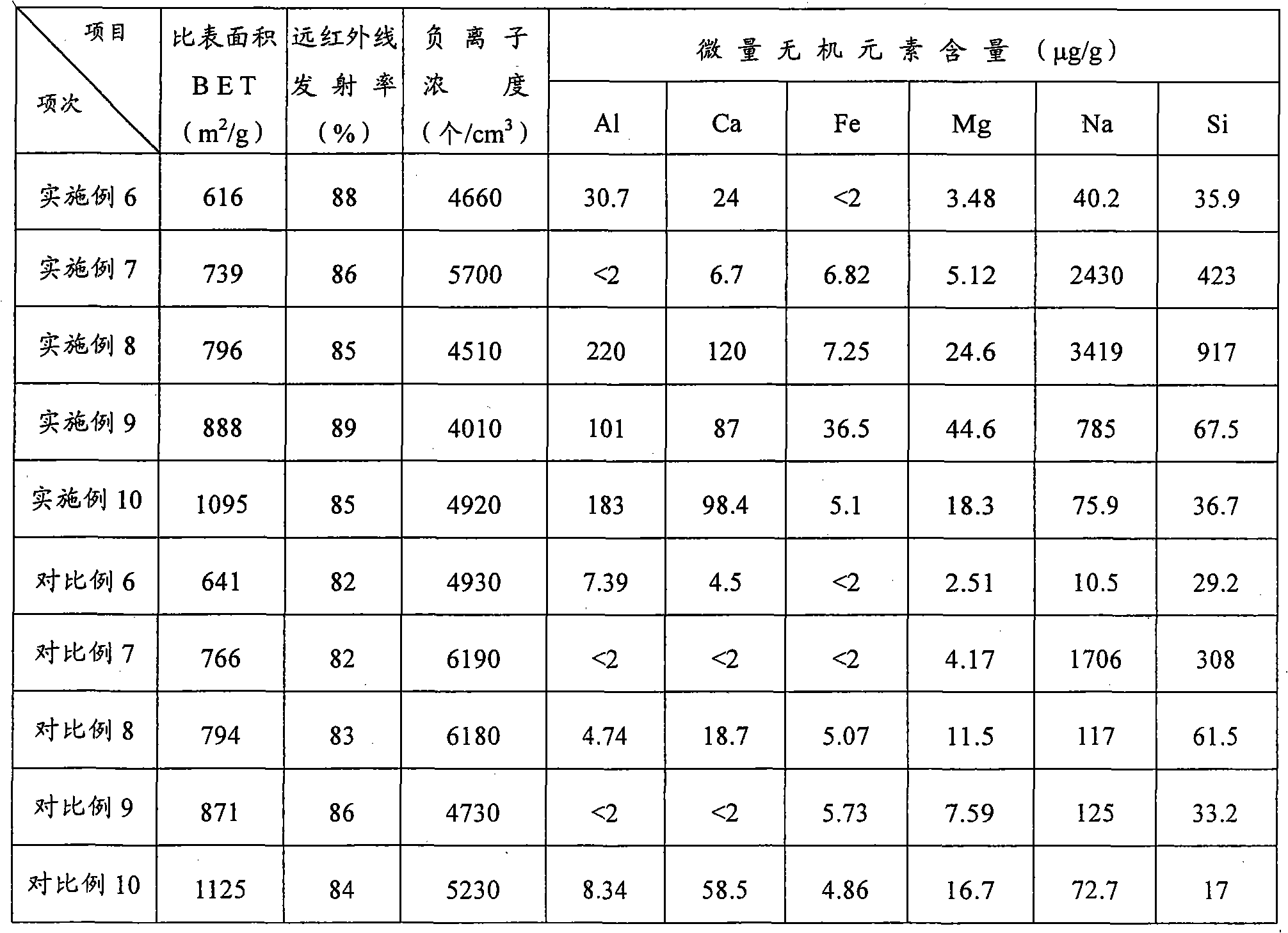

Embodiment 1

[0088] Pyron series polyacrylonitrile-based oxidized fibers produced by Zoltek in the United States are used, and 1 / 1 plain weave is woven into a cloth-like fabric after being spun into yarns. The content of oxidized fibers is 100% by weight, and the weight is 340 to 360g / m 2 .

[0089] The above-mentioned polyacrylonitrile-based oxidized fiber cloth is over-fed into the cloth from the feeding mechanism, and the over-feeding amount of the cloth is controlled (that is, the speed of entering the cloth>the speed of the cloth) to be 15%, and enters the heat treatment furnace through the feed port, and the temperature of the heat treatment furnace At 900°C, water vapor is introduced into the first to fourth areas of the heat treatment furnace, and carbon dioxide is introduced into the fourth area of the heat treatment furnace. The weight ratio of water vapor / carbon dioxide is 10. Cloth outlet, the inlet and outlet of the heat treatment furnace are protected by carbon dioxide gas ...

Embodiment 2

[0092] The Panox series of polyacrylonitrile-based oxidized fibers produced by the British SGL Group are used, and after being spun into yarns, 1 / 1 plain weave is used to form cloth-like fabrics. The content of oxidized fibers is 100% by weight, and the weight is 340 to 360g / m 2 .

[0093] The above-mentioned polyacrylonitrile-based oxidized fiber cloth is overfed into the cloth from the feeding mechanism, and the overfeeding amount of the cloth is controlled (that is, the cloth feeding speed>the cloth outlet speed) to be 20%, and enters the heat treatment furnace through the feeding port, and the temperature of the heat treatment furnace is 20%. The temperature is 965°C, water vapor is introduced into the first to fourth areas of the heat treatment furnace, and carbon dioxide is introduced into the fourth area of the heat treatment furnace. The weight ratio of water vapor / carbon dioxide is 10. Cloth outlet, the inlet and outlet of the heat treatment furnace are protected by...

Embodiment 3

[0096] The Panox series of polyacrylonitrile-based oxidized fibers produced by the British SGL Group are used, and after being spun into yarns, 1 / 1 plain weave is used to form cloth-like fabrics. The content of oxidized fibers is 100% by weight, and the weight is 340 to 360g / m 2 .

[0097] The above-mentioned polyacrylonitrile-based oxidized fiber cloth is over-fed into the cloth from the feeding mechanism, and the over-feeding amount of the cloth is controlled (that is, the speed of entering the cloth>the speed of the cloth) to be 30%, and enters the heat treatment furnace through the feed port, and the temperature of the heat treatment furnace The temperature is 985°C, water vapor is introduced into the first to fourth areas of the heat treatment furnace, and carbon dioxide is introduced into the fourth area of the heat treatment furnace. The weight ratio of water vapor / carbon dioxide is 20. Cloth outlet, the inlet and outlet of the heat treatment furnace are protected by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Longitudinal breaking strength | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com