Non-woven fabric based on polypropylene non-woven fabric recycle and preparation method thereof

A technology of polypropylene non-woven fabric and polypropylene resin, which is applied in the direction of single-component polyolefin artificial filament, non-woven fabric, textile and paper making, and achieves the effects of low production cost, good flexibility and good breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific examples.

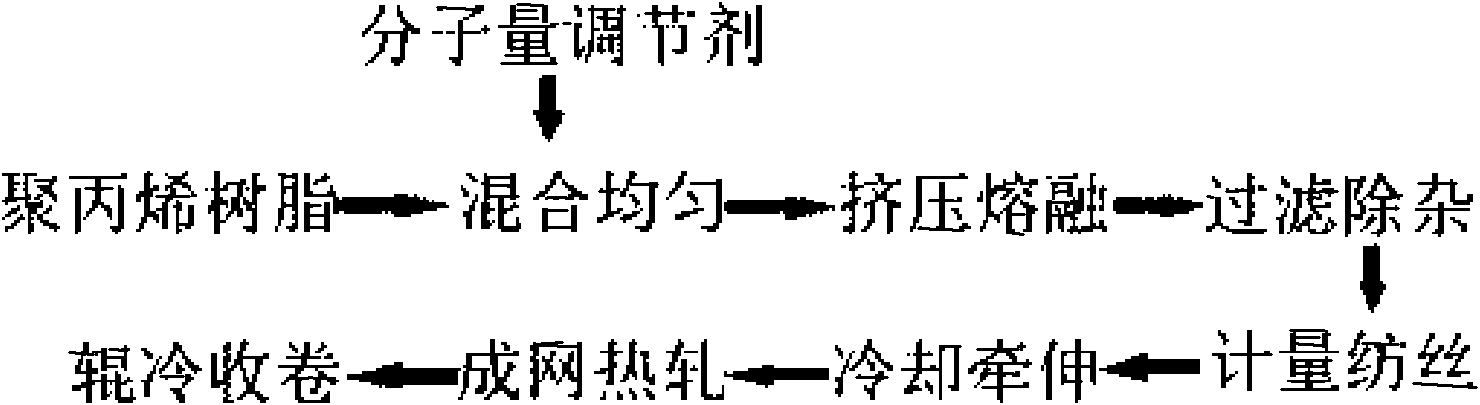

[0020] Embodiment 1~6: preparation steps see figure 1 , see Table 1 for the dosage of each component. Wherein the preparation method of polypropylene resin is as follows: the recycled polypropylene non-woven fabric products are classified, cleaned, dried, and pulverized; respectively take 580 g of dried polypropylene non-woven fabric recycled powder and 1360 g of polypropylene resin pellets, and add 10 g Antioxidant, 30g compatibilizer, 20g nucleating agent, mix uniformly; put uniform mixture into single (twin) screw extruder, melt extrude, after water cooling, pelletize to obtain polypropylene resin.

[0021] Each component consumption (unit: g) in the embodiment of table 1

[0022] Minute

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com