Motherwort cellulose fiber and preparation method thereof

A technology of cellulose fiber and motherwort, which is applied in the direction of single-component cellulose artificial filament, microsphere preparation, fiber chemical characteristics, etc., can solve the problem of short release period of active ingredients of motherwort, affecting product quality, poor antibacterial effect, etc. problem, to achieve the effect of alleviating redness and itching, good antibacterial effect, and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

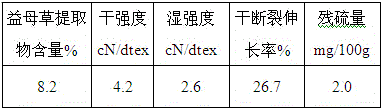

[0037] Example 1 The preparation method of Motherwort cellulose fiber whose specification is 1.67dtex×38mm

[0038] (1) Selection of raw materials

[0039] The motherwort extract is selected as the raw material of motherwort microcapsules. The motherwort extract is a brown powder, 100% passes through an 80 mesh sieve, the motherwort content is 60%, the ash content is ≤3.2%, the water content is ≤3.8%, and the heavy metal content ≤5ppm, lead content≤1ppm, arsenic content≤0.5ppm, mercury content≤0.4ppm, total number of bacteria≤500cfu / g, total number of mold≤50cfu / g, Salmonella and Escherichia coli should not be detected.

[0040] (2) Preparation of motherwort emulsified dispersion

[0041] The motherwort emulsified dispersion liquid is processed and prepared from motherwort extract and peach gum solution; the dosage of the motherwort extract and peach gum solution is calculated according to parts by weight; 5 parts of motherwort extract and 3 parts of peach gum solution are mi...

Embodiment 2

[0076] Example 2 Testing the antiallergic properties of fabrics woven from cellulose fibers of the present invention

[0077] Test parameters: skin redness (visual score), itching (subjective feeling), skin redness area (percentage of initial area)

[0078] Grouping: the present invention group, control group, 30 people in each group;

[0079] Measurement method: Use a specific test blade to drip histamine hydrochloride (5mg / ml) on the skin at the same position on the upper part of the arms of all the subjects, the lowest amount is 0.2ml, and the skin will become red, swollen and itchy after 5 minutes;

[0080] The present invention group wears the clothes that adopt the fiber described in the embodiment of the present invention 1 to make, and the matched group wears the clothes that general cellulose fiber is woven; The specific results are shown in Table 4-5;

[0081] Table 2 Skin redness and swelling (maximum severity value is 10)

[0082]

[0083] Table 3 skin itchin...

Embodiment 3

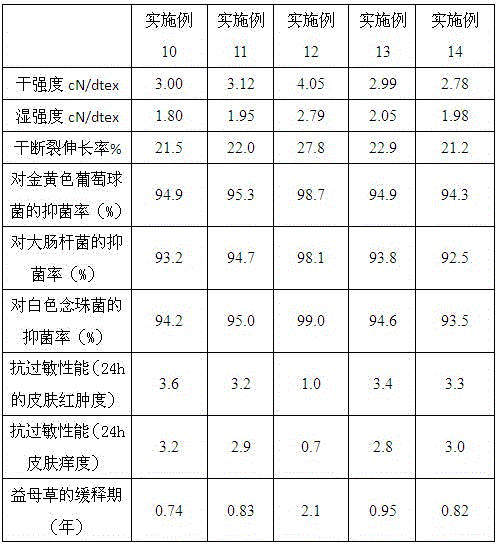

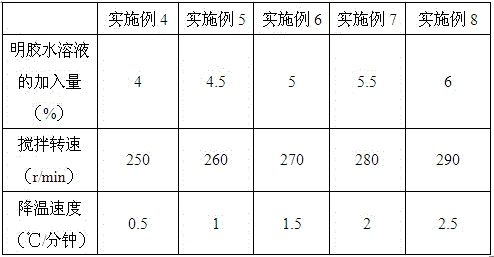

[0086] Example 3 The process parameters for preparing motherwort gelatin solution are optimized

[0087] Using the preparation method of motherwort cellulose fiber described in Example 1, only change step (3) to prepare motherwort gelatin solution, the amount of gelatin aqueous solution, stirring speed, cooling speed, after the cellulose fiber is prepared, the dry strength of the fiber is detected , wet strength, dry elongation at break, sustained release period, the bacteriostatic rate to Staphylococcus aureus, the bacteriostatic rate to Escherichia coli, the bacteriostatic rate to Candida albicans; Adopt the detection method of embodiment 2, detect Anti-allergic properties of fibers (24h skin redness, skin itching).

[0088] Table 4 The multi-factor combination analysis of the process parameters for the preparation of motherwort gelatin solution

[0089]

[0090] Table 5 Analysis of process parameters optimization experiment results for the preparation of motherwort gela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com