Research method silicon substrate surface morphology based on laser control nanostructure

A nanostructure and surface morphology technology, applied in the process of producing decorative surface effects, manufacturing microstructure devices, nanotechnology, etc., can solve the problem of affecting surface morphology, distortion of silicon-based surface morphology, and unsatisfactory silicon-based surface morphology and other problems, to achieve the effect of short time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

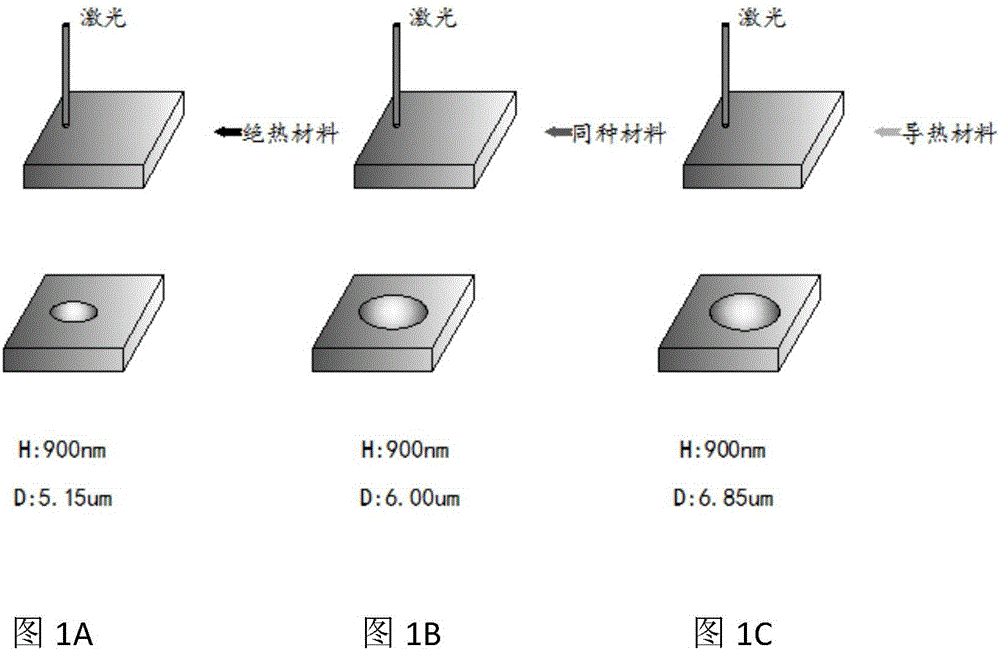

[0036] Use asbestos (thermal insulation material) to touch the right plane of the nanostructure silicon substrate, the thermal conductivity of asbestos k 1 =0W / m-K. Then adjust the power of the laser to P=75mW, and irradiate the surface of the silicon-based material for 10 seconds. After laser irradiation, the silicon substrate was placed under an optical magnifying instrument for observation. The result of observation is that there is a raised silicon-based surface morphology in the center of the silicon substrate, and the corresponding height H=900nm and maximum diameter D=5.15um are measured, and the corresponding aspect ratio is 0.175, as shown in Figure 1A.

Embodiment 2

[0038] Use silicon (the same material) to contact the right plane of the nanostructured silicon substrate, the thermal conductivity of silicon k 2 = 150W / m-K. Repeating the above operations, the corresponding height H=900nm and the largest diameter D=6.00um were measured, and the corresponding aspect ratio was 0.150, as shown in FIG. 1B .

Embodiment 3

[0040] Use aluminum (thermal conductive material) to contact the right plane of the nanostructure silicon substrate, the thermal conductivity of aluminum k 3 = 200W / m-K. Repeat the above operations to measure the corresponding height H=900nm and maximum diameter D=6.85um, and the corresponding aspect ratio is 0.131, as shown in Figure 1C.

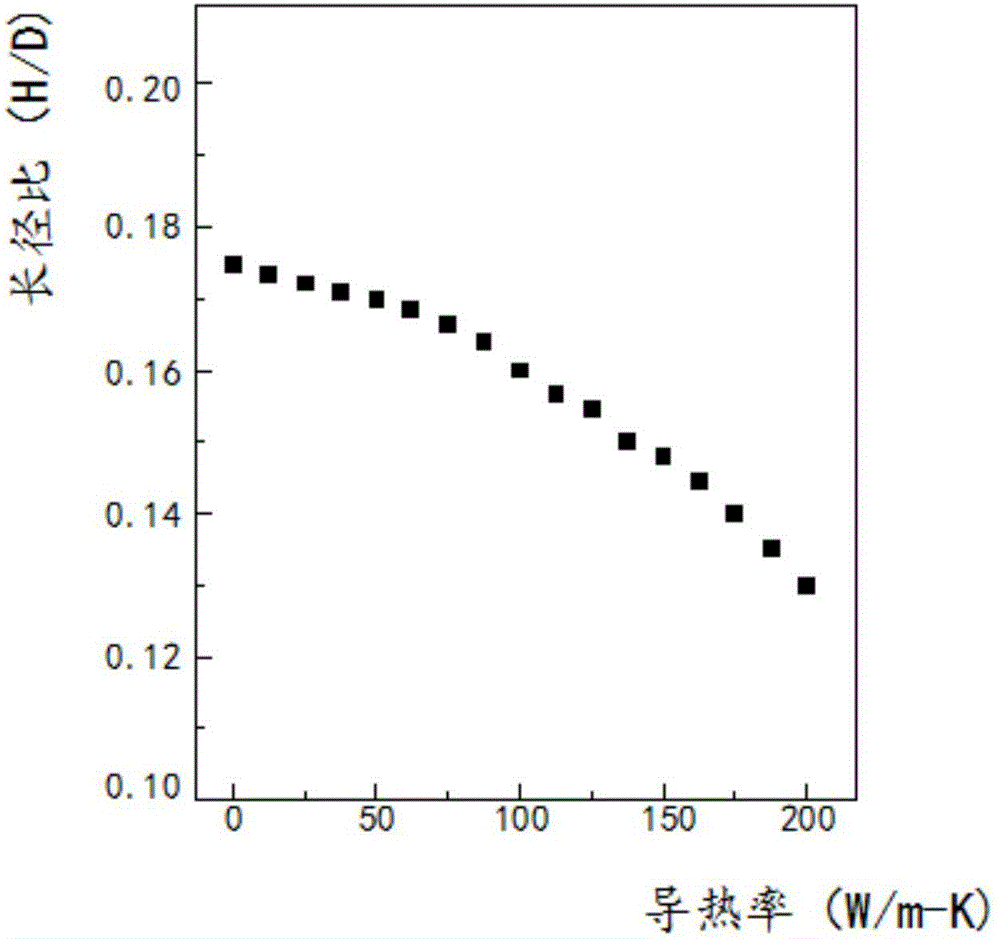

[0041] It can be seen from the above examples that when the thermal conductivity of the contact material gradually increases (the thermal conductivity of asbestos is the lowest, the thermal conductivity of silicon is medium, and the thermal conductivity of aluminum is the highest), the maximum height of the silicon-based surface morphology will not change. The maximum diameter D becomes larger and larger. According to the aspect ratio of the maximum height H / maximum diameter D, it can be obtained that the aspect ratio of the silicon-based surface morphology is getting smaller and smaller.

[0042] The above is to study the aspect ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com