Polyethylene antibacterial film and preparation method and application thereof

A polyethylene film, antibacterial film technology, applied in the direction of transportation and packaging, flexible coverings, coatings, etc., to achieve the effect of easy multifunctional nano-assembly film and surface modification, high product order, and enhanced interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

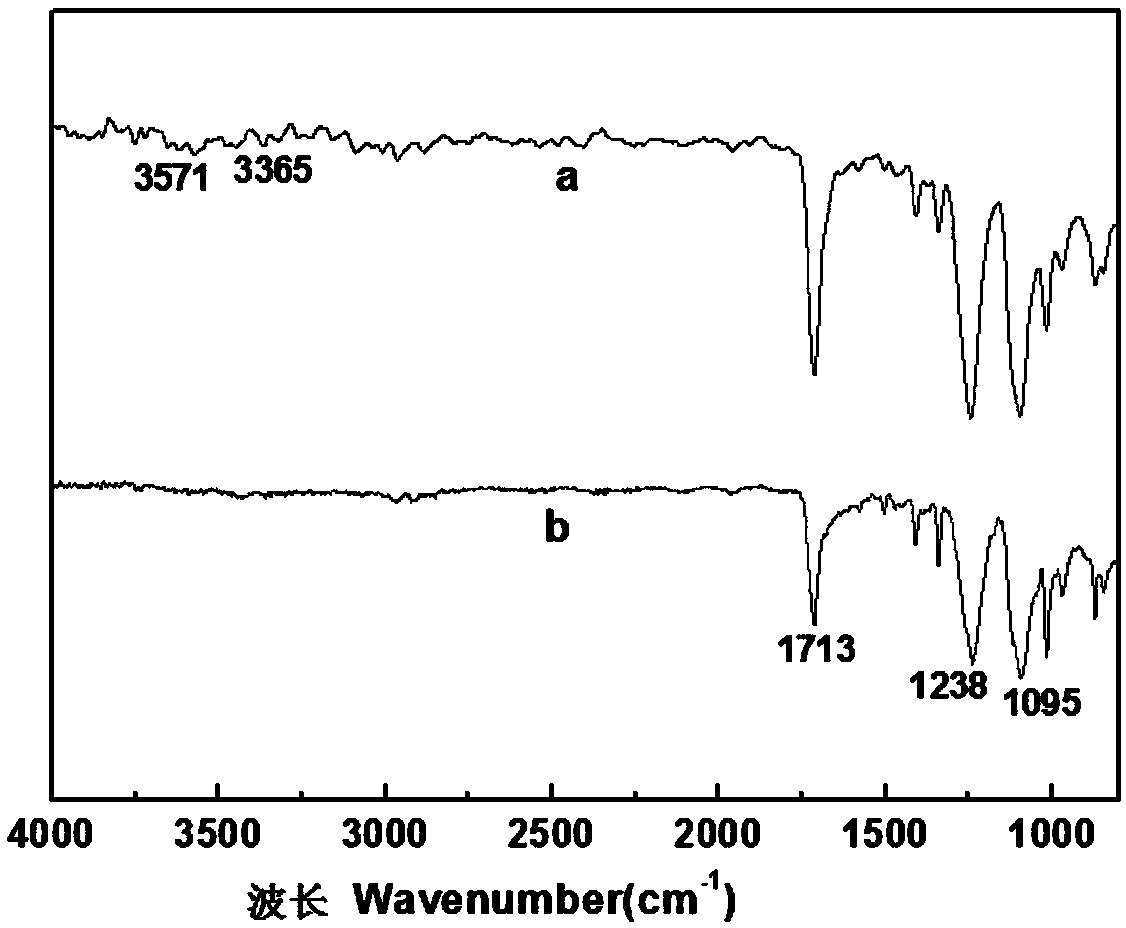

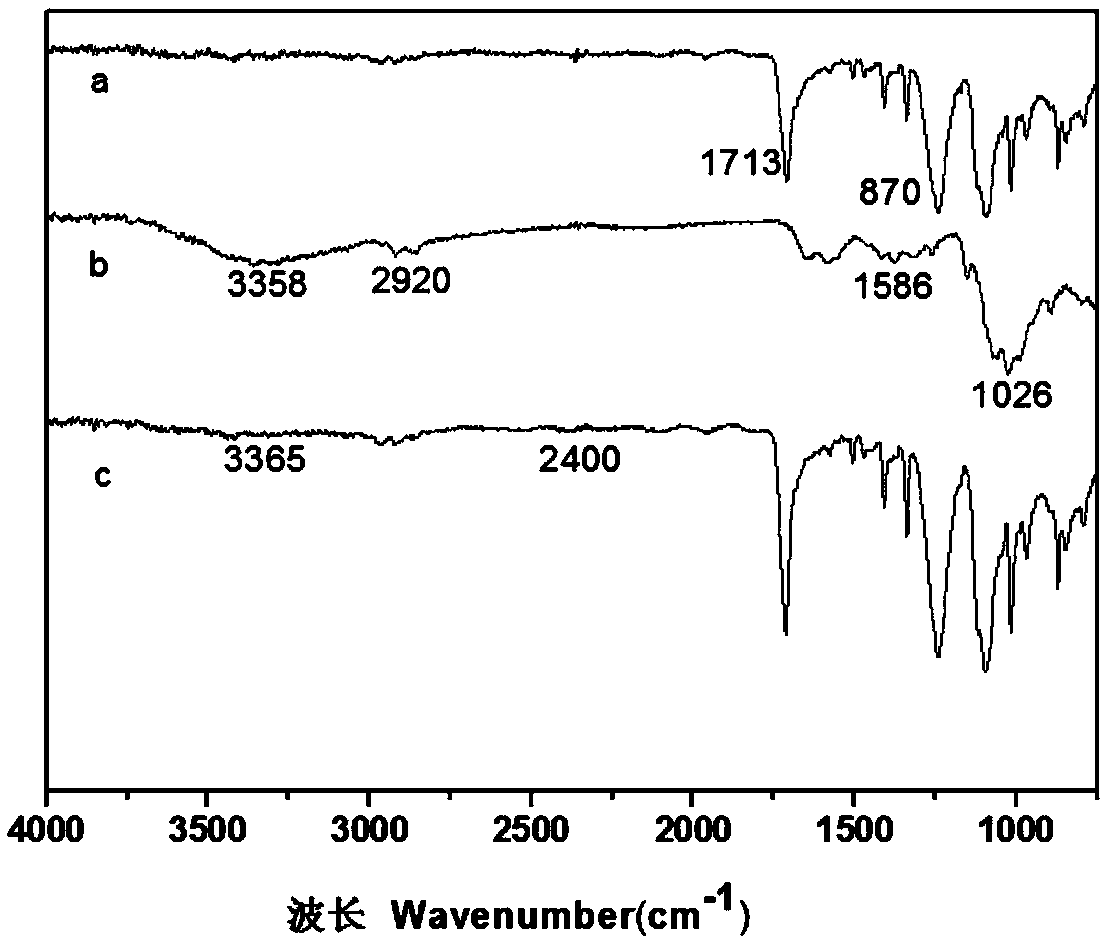

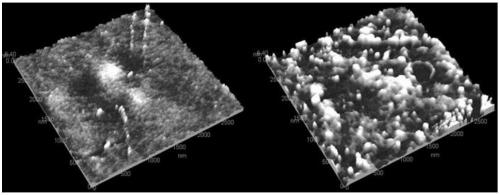

Method used

Image

Examples

Embodiment 1

[0072] The polyethylene antibacterial film provided in this embodiment is made up of polyethylene film, acrylic film and one deck chitosan-lemon essential oil composite film.

[0073] Wherein the polyethylene film is corona treated polyethylene film.

[0074] The acrylic film is a water-based acrylic film.

[0075] The preparation method of this polyethylene antibacterial film, comprises the following steps:

[0076] (1) Preparation of chitosan solution: take 0.2g chitosan and dissolve it in the acetic acid solution with a concentration of 2% (10mL), stir in a magnetic stirrer for 1 hour, and prepare 10mL with a concentration of 2% (w / v ) chitosan solution;

[0077] (2) Preparation of lemon essential oil solution: Dissolve 2 mL of lemon essential oil into 8 mL of deionized water with a pipette, and add 0.4% (w / v, the amount of Tween 80 accounts for 0.4% to 0.6% of the total volume of lemon essential oil and water) Tween 80, stirred in a magnetic stirrer for 1 hour, and was ...

Embodiment 2

[0082] The difference from Example 1 is that the volume ratios of chitosan CTS:lemon essential oil in step (3) are 8:0, 6:2 and 0:8.

Embodiment 3

[0084] The difference from Example 1 is that the volume ratios of chitosan CTS:lemon essential oil in step (3) are 8:0, 2:6 and 0:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com