Preparation method of shiitake mushroom stick

A technology of shiitake mushroom sticks and shiitake mushrooms, applied in botany equipment and methods, mushroom cultivation, gardening, etc., can solve environmental pollution and other problems, and achieve the effects of improving cell vitality, high economic benefits, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

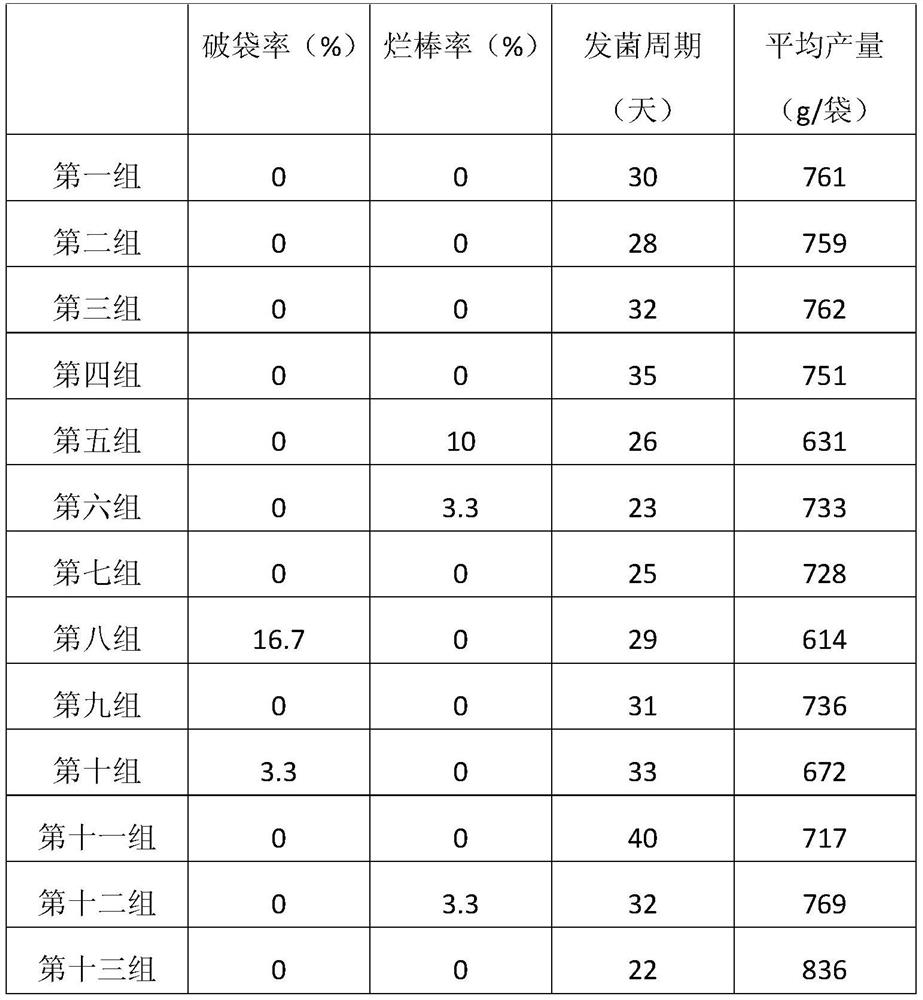

Examples

Embodiment 1

[0024]This embodiment provides a method for preparing shiitake mushroom sticks. The method includes the following steps:

[0025](1) Preparation of culture material: Prepare culture material for fungus sticks according to the following parts by weight: 10 parts of wheat bran, 1 part of peptide powder, 20 parts of sawdust, 3 parts of diethyl aminoethyl hexanoate, iodine powder, 6 parts of pomegranate seed residue, 2 parts of gypsum, 5 parts of mushroom production factor, 2 parts of sodium nitrophenolate, 1 part of yeast and 1 part of microcystin; the pomegranate seed residue is obtained by the following method: a. After crushing the pomegranate seeds, add guanidine to it Salt-like ionic liquid, stirred for 40 minutes, then added 2 times the volume of water of the material obtained after the stirring treatment, stirred again for 40 minutes, collected the precipitate by centrifugation, and dried the precipitate in vacuum to obtain pomegranate seed powder, in the pomegranate seed powder Ad...

Embodiment 2

[0030](1) Preparation of culture material: Prepare culture material for fungus bar according to the following parts by weight: 12 parts of wheat bran, 2 parts of peptide powder, 24 parts of sawdust, 4 parts of diethyl aminoethyl hexanoate, 2 parts of iodine powder, 9 parts of pomegranate seed residue , 2 parts of gypsum, 7 parts of lentinus edodes, 3 parts of sodium nitrophenolate, 2 parts of yeast and 2 parts of microcystin; the pomegranate seed residue is obtained by the following method: a. The pomegranate seeds are crushed and added to it Guanidine salt ionic liquid, stirred for 42 minutes, and then added 3 times the volume of water of the material obtained after the stirring treatment, stirred again for 45 minutes, collected the precipitate by centrifugation, and dried the precipitate in vacuum to obtain pomegranate seed powder. Add 4 times the mass of water and mix well, and then add cellulase enzymatic hydrolysis to it for 7 hours to obtain the pomegranate seed residue; the c...

Embodiment 3

[0035](1) Preparation of culture material: Prepare culture material for fungus bar according to the following parts by weight: 15 parts of wheat bran, 2 parts of peptide powder, 28 parts of sawdust, 5 parts of diethyl aminoethyl hexanoate, 2 parts of iodine powder, 12 parts of pomegranate seed residue , 3 parts of gypsum, 10 parts of lentinus edodes, 4 parts of sodium nitrophenolate, 2 parts of yeast and 3 parts of microcystin; the pomegranate seed residue is obtained by the following method: a. The pomegranate seed is crushed and added to it Guanidine salt ionic liquid, stirred for 45 minutes, and then added 4 times the volume of water of the material obtained after the stirring treatment, stirred again for 50 minutes, collected the precipitate by centrifugation, and vacuum dried the precipitate to obtain pomegranate seed powder. Add 5 times the mass of water and mix well, and then add cellulase enzymatic hydrolysis to it for 8 hours to obtain the pomegranate seed residue; the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com