Furfural-acetone epoxy cement terrace coating

A floor coating and furfuryl ketone epoxy technology, which is applied in the field of floor paint, can solve the problems of floor coating hardness, wear resistance and compressive strength that cannot meet the moving load, affect the appearance and service life of the floor, and peeling, etc. , to achieve the effect of improving crack resistance, good impact and wear resistance and durability, and reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

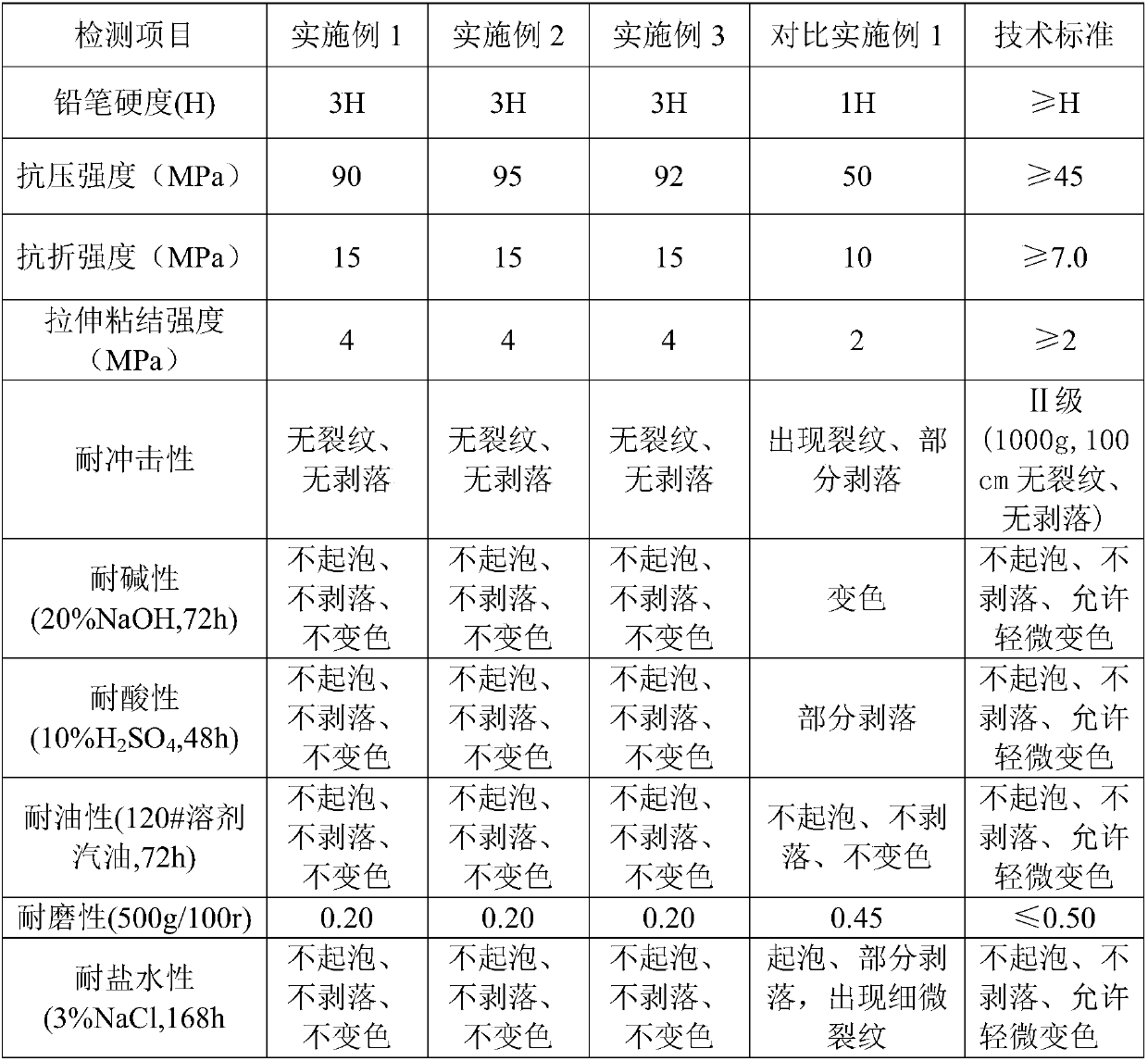

Examples

Embodiment 1

[0022] Furfurone epoxy cement floor paint, said furfurone epoxy cement floor paint comprises A component, B component and C component mixed with each other; : Formulated with a weight ratio of 1:1: the A component includes the following raw materials in parts by weight: 60 parts of E-51 epoxy resin, 45 parts of furfurone resin, and 2.5 parts of long-chain alkyl glycidyl ether , 10 parts of butyl glycidyl ether, 0.5 parts of EFKA-2040, 0.3 parts of EFKA-3650 and 0.2 parts of EFKA-4310; the B component includes the following raw materials in parts by weight: 10 parts of modified fatty amine, salicyl 5 parts of acid and 1 part of quaternary ammonium salt; the C component includes the following raw materials in parts by weight: 60 parts of cement and 12 parts of toner.

[0023] Wherein, the preparation method of described furfurone epoxy cement floor coating specifically comprises the steps:

[0024] S1. Preparation of component A: Add furfurone resin to long-chain alkyl glycidyl...

Embodiment 2

[0028] Furfurone epoxy cement floor paint, said furfurone epoxy cement floor paint comprises A component, B component and C component mixed with each other; : Formulated with a weight ratio of 1:1: the A component includes the following raw materials in parts by weight: 70 parts of E-51 epoxy resin, 55 parts of furfurone resin, and 3.5 parts of long-chain alkyl glycidyl ether , 15 parts of butyl glycidyl ether, 0.8 parts of EFKA-2040, 0.6 parts of EFKA-3650 and 0.7 parts of EFKA-4310; the B component includes the following raw materials in parts by weight: 15 parts of modified fatty amine, salicyl 6 parts of acid and 3 parts of quaternary ammonium salt; the C component includes the following raw materials in parts by weight: 70 parts of cement and 15 parts of toner.

[0029]Wherein, the preparation method of described furfurone epoxy cement floor coating specifically comprises the steps:

[0030] S1. Preparation of component A: Add furfurone resin to long-chain alkyl glycidyl...

Embodiment 3

[0034] Furfurone epoxy cement floor paint, said furfurone epoxy cement floor paint comprises A component, B component and C component mixed with each other; : Formulated with a weight ratio of 1:1: the A component includes the following raw materials in parts by weight: 655 parts of E-51 epoxy resin, 50 parts of furfurone resin, and 3 parts of long-chain alkyl glycidyl ether , 13 parts of butyl glycidyl ether, 0.6 part of EFKA-2040, 0.4 part of EFKA-3650 and 0.5 part of EFKA-4310; the B component includes the following raw materials by weight: 12 parts of modified fatty amine, salicyl 5 parts of acid and 2 parts of quaternary ammonium salt; the C component includes the following raw materials in parts by weight: 65 parts of cement and 14 parts of toner.

[0035] Wherein, the preparation method of described furfurone epoxy cement floor coating specifically comprises the steps:

[0036] S1. Preparation of component A: Add furfurone resin to long-chain alkyl glycidyl ether and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com