Container for conveying substrate, inner wall structure of the container, and bottom raising member used for the container

A substrate handling and container technology, which is applied in containers, thermal insulation containers, containers for preventing mechanical damage, etc., can solve the problems of desiccant damage to glass substrates, easy deterioration of support grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0148] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

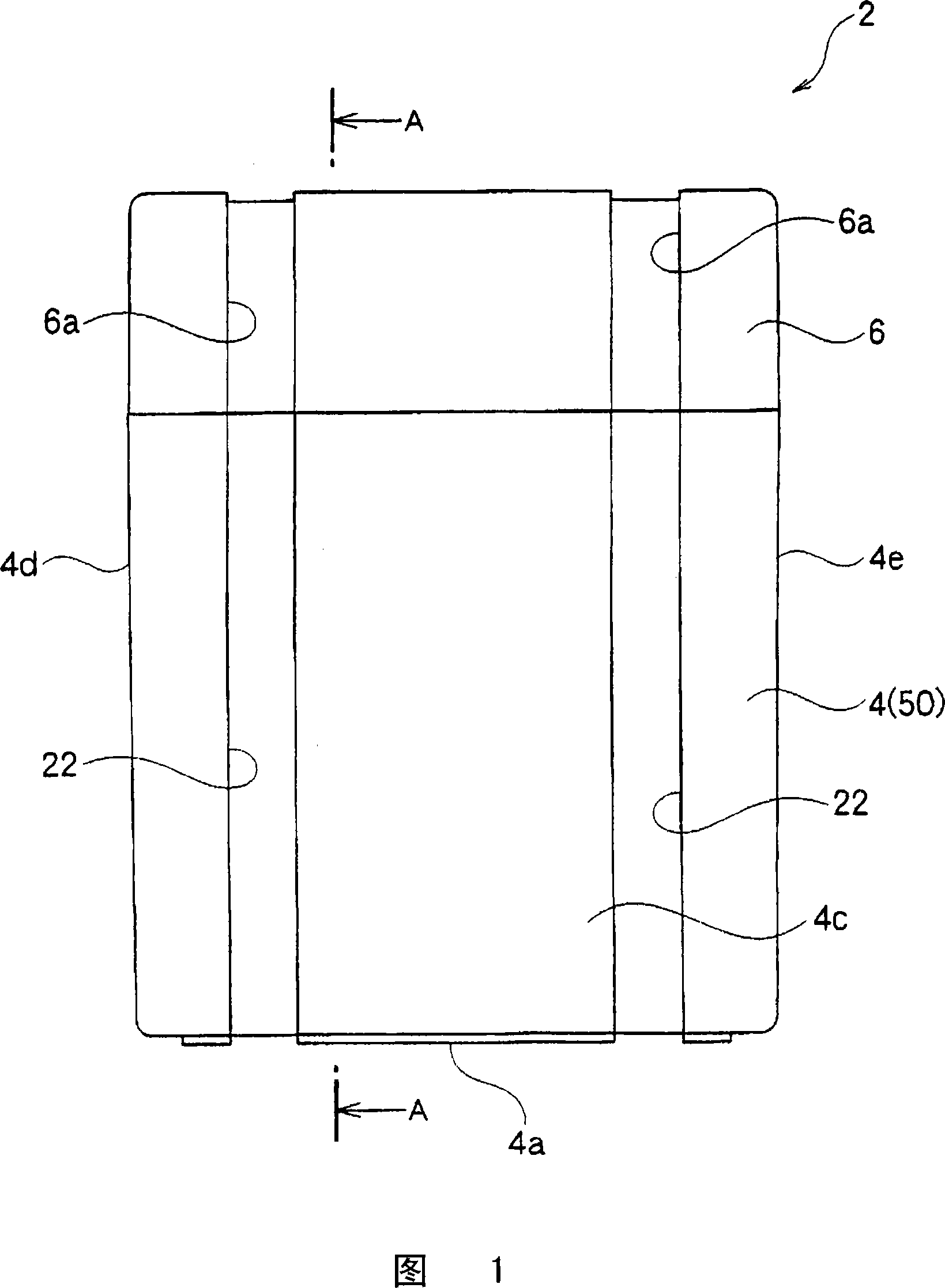

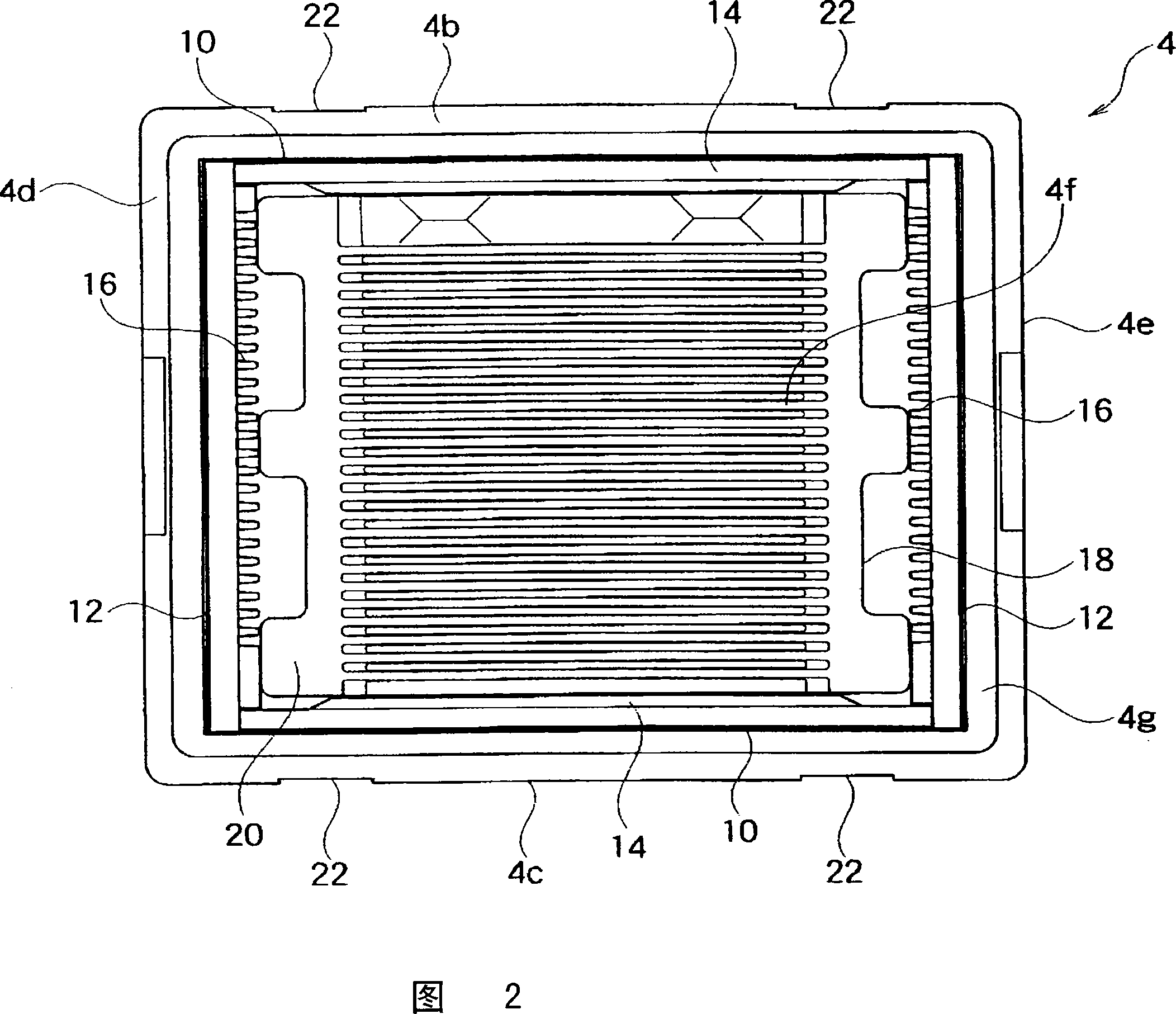

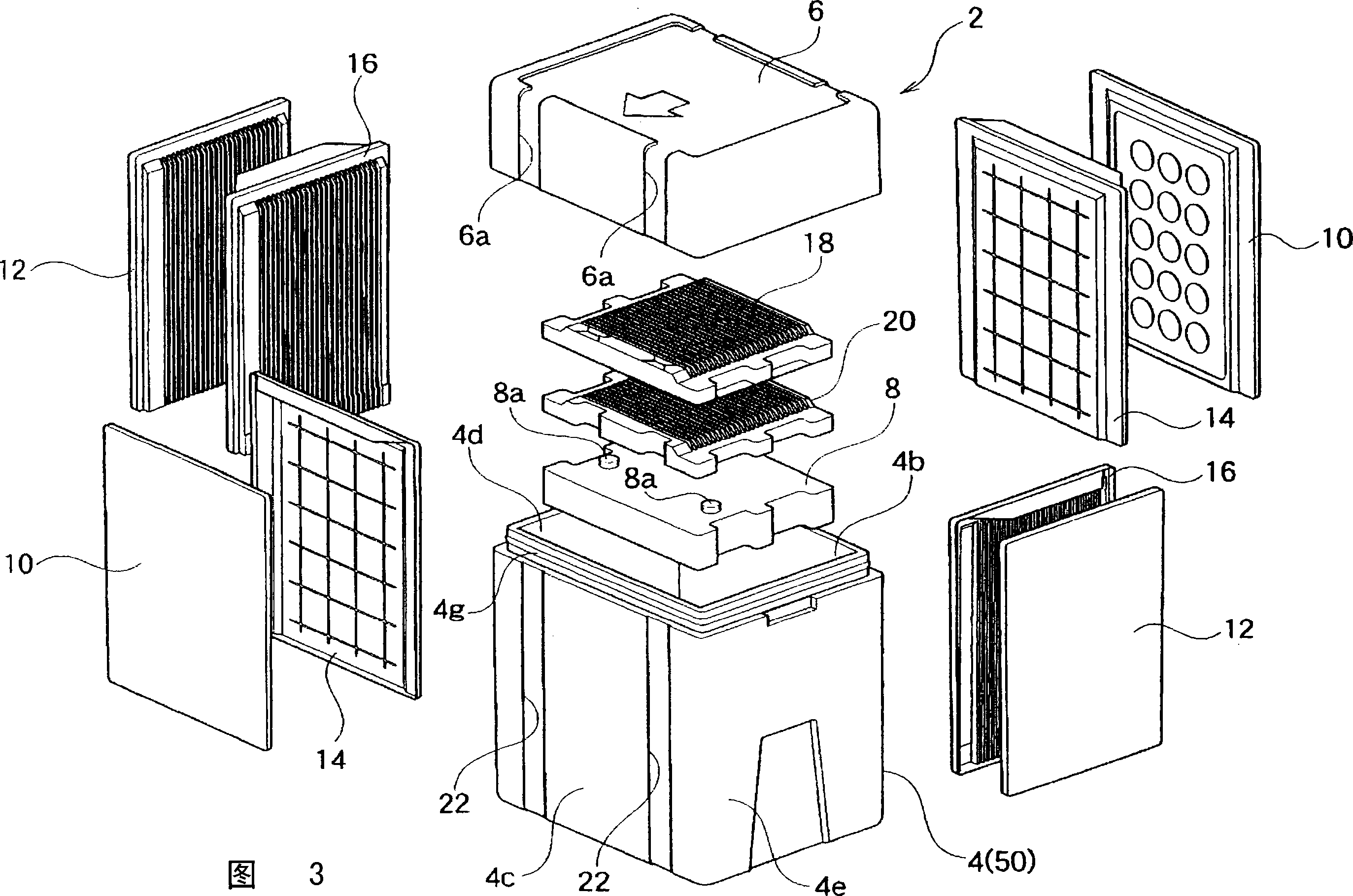

[0149] 1 is a front view of a substrate transfer container according to an embodiment of the present invention, and FIG. 2 is a plan view of a container main body when an upper lid is removed from the substrate transfer container shown in FIG. 1 . 3 is an exploded cross-sectional view of the substrate transfer container shown in FIG. 1 , FIG. 4 is a cross-sectional view of the substrate transfer container in the width direction, and FIG. 5 is a longitudinal cross-sectional view of the substrate transfer container.

[0150] If the substrate transfer container of this embodiment is briefly described, a plate-shaped heat insulator is arranged in a double-layer structure inside the box-shaped outer container formed of foamed synthetic resin, and the entire inside thereof is covered. A resin sheet is placed on the inner surface.

[0151] That is, the substrate transfer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com