Automobile air vent shell fastener press mounting equipment

A technology for air vents and casings, which is applied in the field of press-fitting equipment for car air vent casings, can solve the problems of low labor production efficiency, high labor intensity of workers, easy occurrence of defective products, etc., and achieves simple structure and high processing efficiency. , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

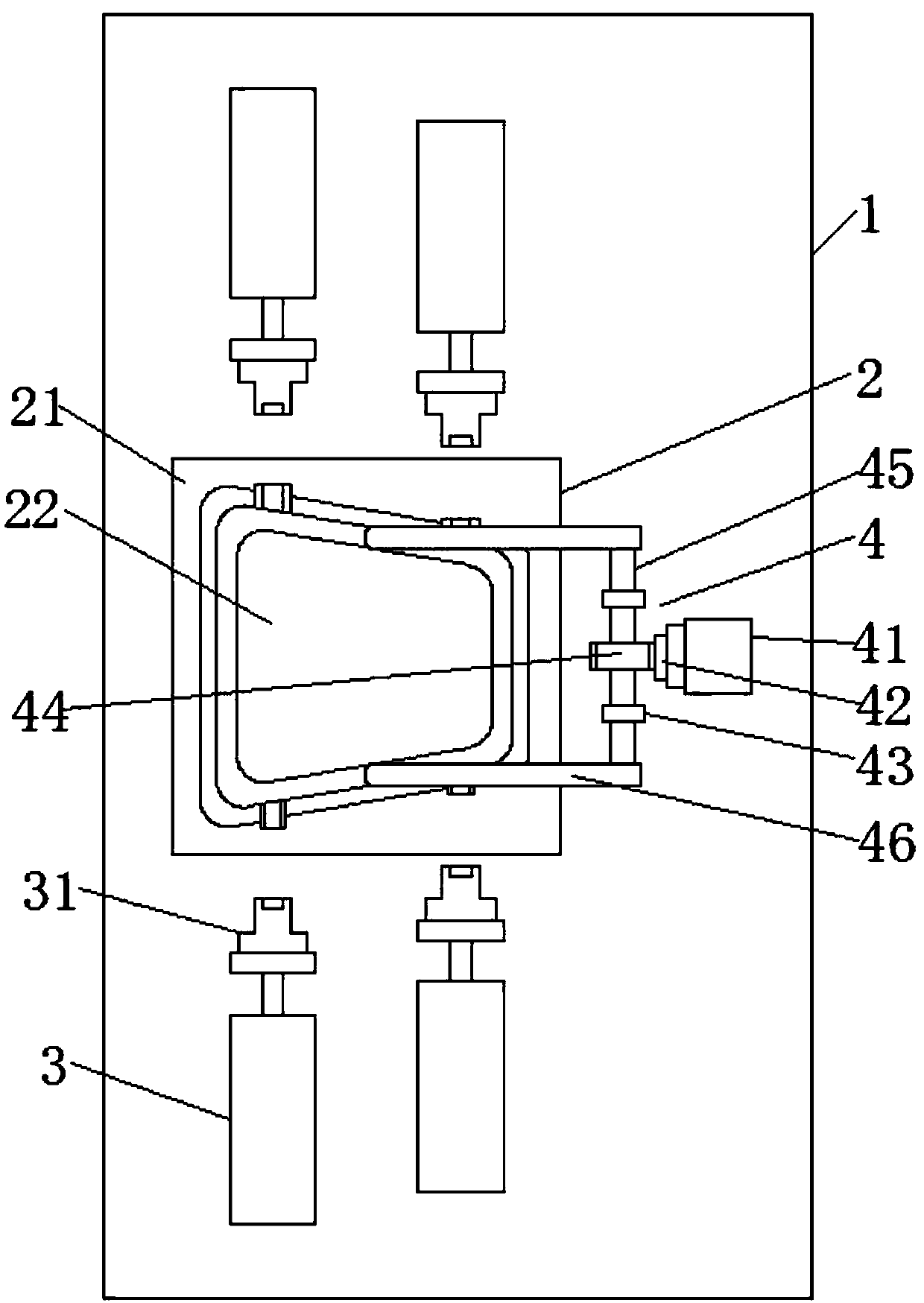

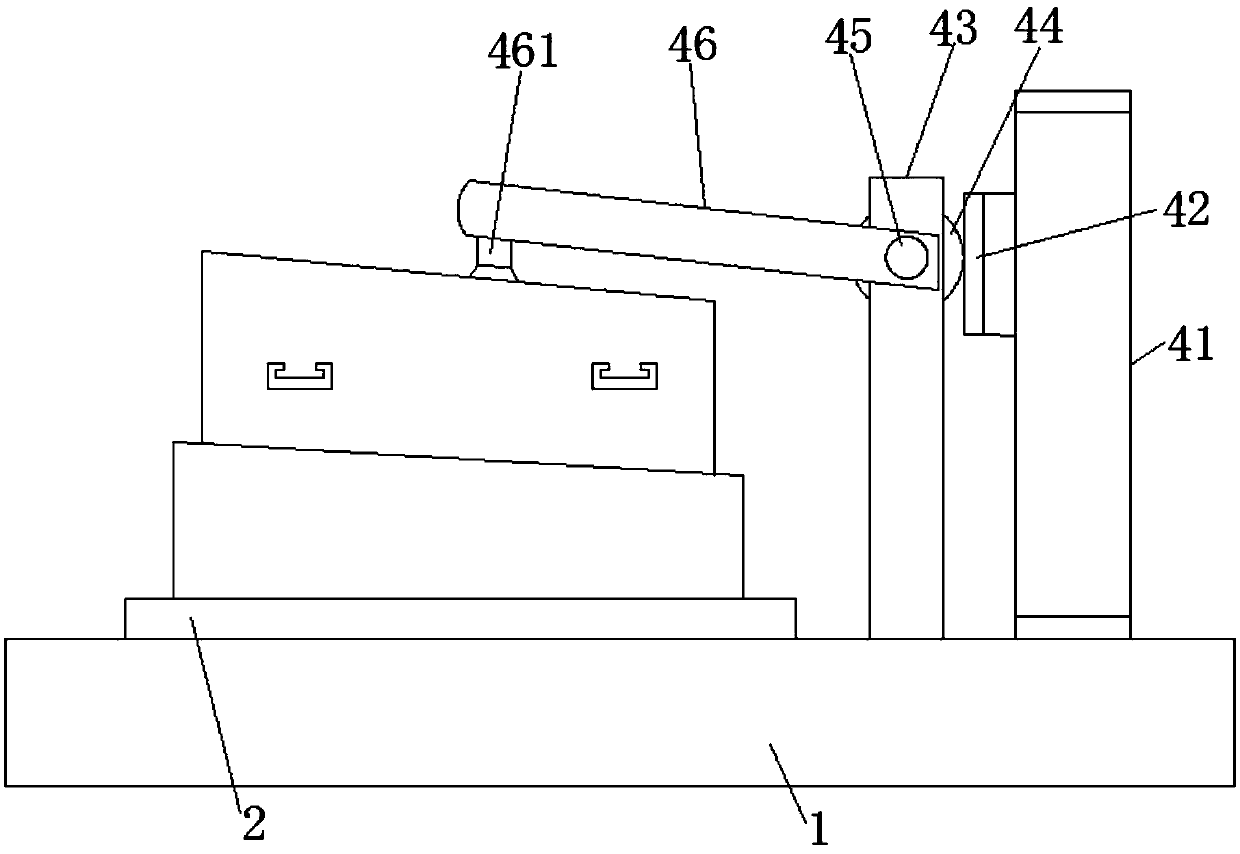

[0030] Example: such as figure 1 and 2 As shown, the automobile air vent shell clip press-fitting equipment of this embodiment is a shell with a hollow interior and openings at both ends, and clip press-fit seats are symmetrically provided on the outer walls of its opposite sides, which is characterized in that : Including workbench 1, press-fitting platform 2, multiple press-fitting mechanisms 3 and workpiece pressing mechanism 4;

[0031] The above-mentioned press-fitting table 2 is installed on the above-mentioned workbench 1 to fix the vent housing to be press-fitted;

[0032] A plurality of the above-mentioned press-fitting mechanisms 3 are respectively installed on the above-mentioned workbench 1 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com