Dental implant with micron-nanometer multi-grade micro-surface structure and preparation method

A dental implant and nanotechnology, applied in dentistry, dental implants, dentures, etc., can solve the problems of insufficient bonding force between the surface structure and the substrate, and achieve the effect of increasing the activity of osteoblasts, accelerating the formation and stabilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) After the titanium specimen leaves the factory, after removing the passivation film on the surface, place it in acetone, 95% ethanol, and deionized water for ultrasonic cleaning for 10 minutes, and then dry it;

[0022] (2) Preparation of electrolyte: concentration of hydrofluoric acid: 7.3mol / L; concentration of hydrochloric acid: 0.5mol / L;

[0023] (3) Electrode setting: the anode is a titanium dental implant, and the cathode is a platinum sheet;

[0024] (4) Processing parameters: solution temperature 12°C, etching time 6min, current density 500mA / cm 2 ;

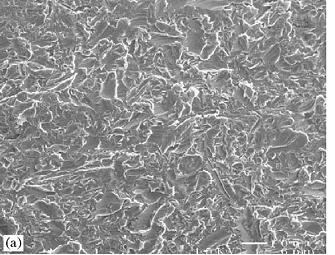

[0025] (5) After the titanium dental implant treated in step (1) was placed in the electrolyte for treatment, it was then placed in acetone, 95% ethanol, and deionized water for ultrasonic cleaning and drying; to form a micron- -Nano-microstructured surface to obtain bowl-shaped micro-concaves on the titanium surface: about 20-50 μm in diameter, micropores: about 2-5 μm in diameter, nano-cavities, nanopores a...

Embodiment 2

[0027] (1) After the titanium specimen leaves the factory, after removing the passivation film on the surface, place it in acetone, 95% ethanol, and deionized water for ultrasonic cleaning for 10 minutes, and then dry it;

[0028] (2) Electrolyte solution prepared in the electrolytic cell: concentration of hydrofluoric acid: 0.2mol / L; concentration of hydrochloric acid: 11.5mol / L;

[0029] (3) Electrode setting: the anode is a titanium dental implant, and the cathode is a platinum sheet;

[0030] (4) Processing parameters: solution temperature 50°C, etching time 1.5min, current density 100mA / cm 2 ;

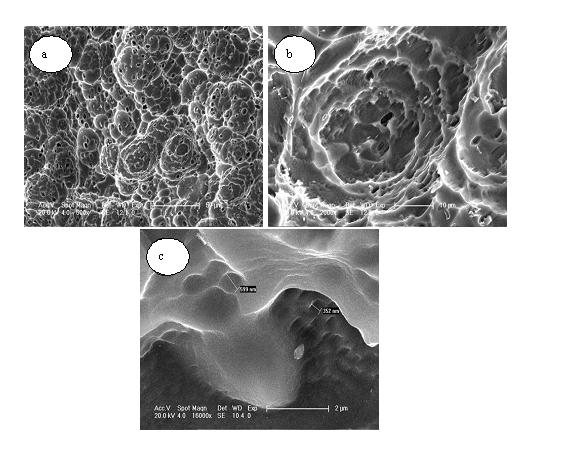

[0031] (5) After the titanium dental implant treated in step (1) was placed in the electrolyte for treatment, it was then placed in acetone, 95% ethanol, and deionized water for ultrasonic cleaning and drying; to make the surface of the specimen form a micron- - Nanostructured surfaces (see figure 2 ).

Embodiment 3

[0033] (1) After the titanium specimen leaves the factory, after removing the passivation film on the surface, place it in acetone, 95% ethanol, and deionized water for ultrasonic cleaning for 10 minutes, and then dry it;

[0034] (2) Electrolyte solution prepared in the electrolytic cell: concentration of hydrofluoric acid: 5.6mol / L; concentration of hydrochloric acid: 5.8mol / L;

[0035] (3) Electrode setting: the anode is a titanium dental implant, and the cathode is a platinum sheet;

[0036] (4) Processing parameters: solution temperature 22°C, etching time 5min, current density 950mA / cm 2 ;

[0037] (5) After the titanium dental implant treated in step (1) was placed in the electrolyte for treatment, it was then placed in acetone, 95% ethanol, and deionized water for ultrasonic cleaning and drying; to make the surface of the specimen form a micron- - Nanostructured surfaces (see figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com