Composite conductive ink-jet ink and preparation method thereof

A technology of composite conductive and inkjet ink, which is applied in the field of ink, can solve problems such as leakage of nano-silver particles, affect printing effect, and discontinuous conductive layer of paper, so as to achieve easy nozzle blockage, increased formation, and good inkjet continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

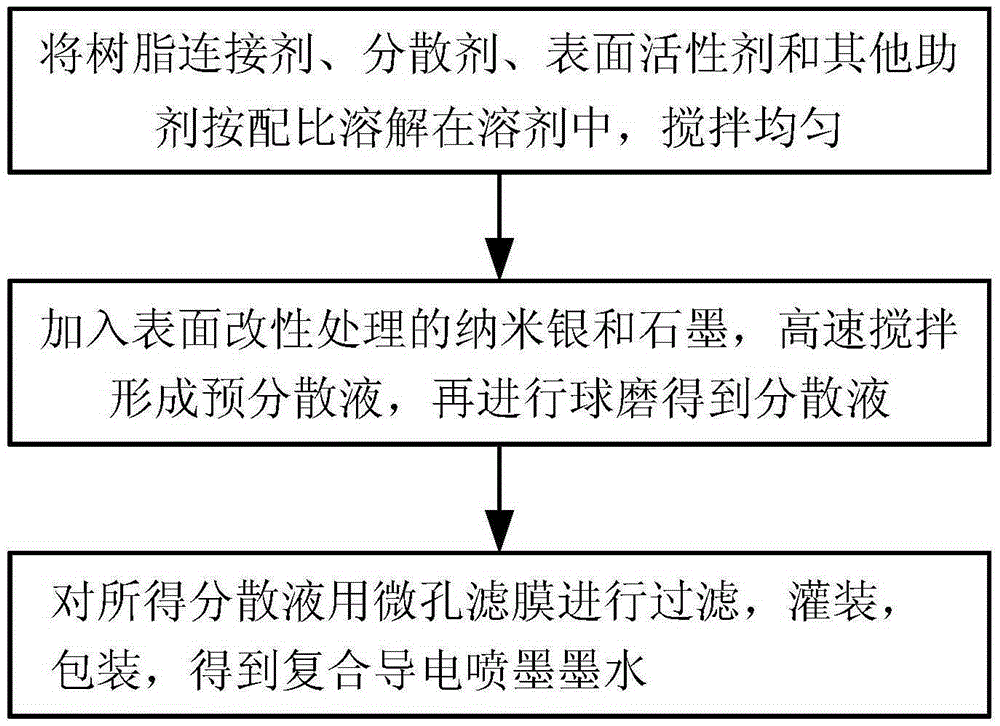

[0037] The preparation method of conductive inkjet ink among the present invention, comprises the following steps:

[0038] Dissolve the resin linking agent, dispersant, surfactant and other additives in the solvent according to the ratio, stir evenly, then add surface-modified nano-silver and graphite, and stir at high speed for 60-240min to form a pre-dispersion. Then transfer the pre-dispersed liquid to a ball mill, ball mill for 2-8 hours, filter the obtained dispersed liquid with a 200-600 nm microporous filter membrane, fill and pack to obtain a composite conductive inkjet ink.

Embodiment 1

[0041] Nano silver: 8g, graphite: 16g, SpredoxD-260: 3g, acrylic resin S-70: 5g, Span 80: 2g, glycerol: 2g, polyether modified silicone defoamer: 0.5g, dioxide Silica sol: 1g, water: 62.5g

[0042] Dissolve in the solvent according to the ratio, stir evenly, then add surface-modified nano-silver and graphite, and stir at high speed for 60 minutes to form a pre-dispersion. Then the pre-dispersed liquid is transferred to the ball mill, ball milled for 4h, and the obtained dispersion liquid is filtered with a 500nm microporous membrane, filled and packaged to obtain a composite conductive inkjet ink. The surface tension of the ink obtained is 49.25mN / m, and the viscosity is 10mpa.s, the conductivity is 8.4μΩ·cm.

Embodiment 2

[0044] Nano silver: 10g, graphite: 10g, SpredoxD-260: 5g, acrylic resin S-70: 5g, Span 80: 2g, glycerol: 2g, polyether modified silicone defoamer: 0.5g, dioxide Silica sol: 1g, water: 64.5g

[0045] Dissolve in the solvent according to the ratio, stir evenly, then add surface-modified nano-silver and graphite, and stir at high speed for 60 minutes to form a pre-dispersion. Then the pre-dispersed liquid is transferred to the ball mill, ball milled for 4h, and the obtained dispersion liquid is filtered with a 500nm microporous membrane, filled and packaged to obtain a composite conductive inkjet ink, the surface tension of the ink is 45.25mN / m, and the viscosity is 9.8mpa.s, sheet resistance is 6.2μΩ·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com