Organic silicone emulsion and production technology thereof

A technology of silicone emulsion and production process, applied in the field of polymer emulsion, can solve problems such as uneven mixing, difficult storage and transportation, unstable silicone emulsion, etc., achieve uniform and stable mixing, improve solubility and viscosity, and enhance mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

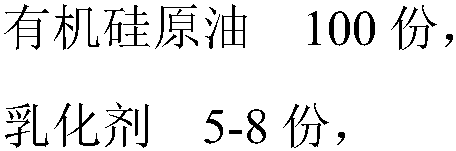

[0036] A kind of organosilicon emulsion, described organosilicon emulsion by weight parts:

[0037]

[0038] A kind of production technology of silicone emulsion as described above, described preparation method is as follows:

[0039] (a) Measure and weigh the silicone crude oil, emulsifier and co-emulsifier respectively for subsequent use;

[0040] (b) adding the organosilicon crude oil, emulsifier and co-emulsifier measured and weighed in the step (1) to the container, and adding the mixture of glacial acetic acid and water dropwise while stirring to obtain the mixture;

[0041] (c) The mixture is stirred at a high speed of 800 r / min for 4 hours, and the finished silicone emulsion is obtained after stirring evenly.

Embodiment 2

[0043] A kind of organosilicon emulsion, described organosilicon emulsion by weight parts:

[0044]

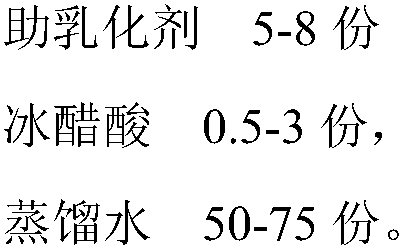

[0045] The preparation method of described epoxy-terminated organosilicon hyperbranched resin is as follows:

[0046] (1) Take a three-necked flask, under the protection of nitrogen, add 100 parts of vinyltrimethoxysilane, 190 parts of dimethylchlorosilane, 100 parts of tetrahydrofuran and 2 parts of ferric chloride, stir and react at 45°C for 3 hours, and then Lower the temperature to room temperature, add 5 parts of activated carbon, filter after stirring for 30 minutes, distill off tetrahydrofuran, and then carry out distillation to obtain tris(dimethylsiloxy)vinylsilane;

[0047] (2) Get a three-necked flask, under nitrogen protection, add 100 parts of tris(dimethylsiloxy)vinylsilane obtained in step (1) and 50 parts of toluene, then add 0.2 part of Castel catalyst, and heat up to 100°C, stirred and reacted for 5 hours to obtain a hydrogen-terminated hyperbranched resi...

Embodiment 3

[0057] A kind of organosilicon emulsion, described organosilicon emulsion by weight parts:

[0058]

[0059] The preparation method of described epoxy-terminated organosilicon hyperbranched resin is as follows:

[0060] (1) Take a three-necked flask, under the protection of nitrogen, add 100 parts of vinyltrimethoxysilane, 190 parts of dimethylchlorosilane, 100 parts of tetrahydrofuran and 2 parts of ferric chloride, stir and react at 45°C for 3 hours, and then Lower the temperature to room temperature, add 5 parts of activated carbon, filter after stirring for 30 minutes, distill off tetrahydrofuran, and then carry out distillation to obtain tris(dimethylsiloxy)vinylsilane;

[0061] (2) Get a three-necked flask, under nitrogen protection, add 100 parts of tris(dimethylsiloxy)vinylsilane obtained in step (1) and 50 parts of toluene, then add 0.2 part of Castel catalyst, and heat up to 100°C, stirred and reacted for 5 hours to obtain a hydrogen-terminated hyperbranched resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com