Composite biological activated carbon and rapid preparation method thereof

A technology of biological activated carbon and raw materials, applied in the field of composite biological activated carbon and its preparation, can solve the problems of poor adsorption capacity of granular carbon, few varieties, and uneven quality, so as to expand the market application space, reduce the cost of carbon production, and shorten the carbonization time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

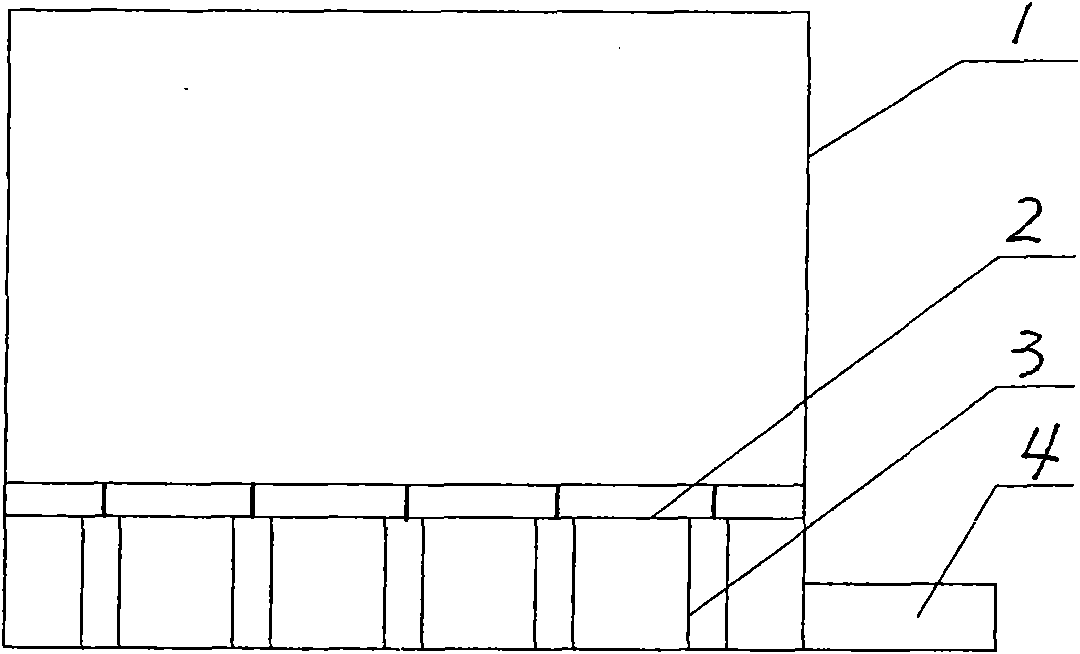

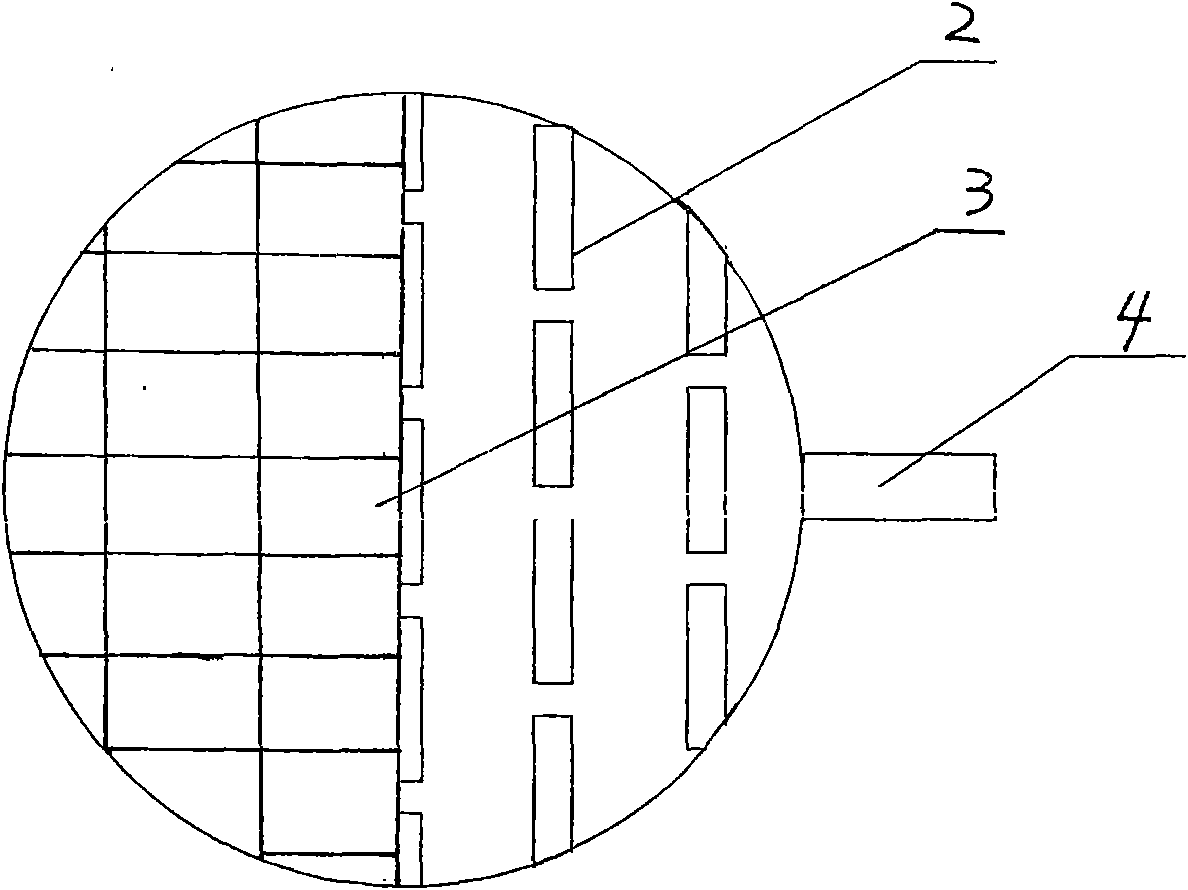

[0015] Such as figure 1 As shown, the furnace body 1 of the carbonization furnace of the present invention is an open cylinder, and several rows of vertical bricks 2 are arranged at the bottom of the furnace. Each row of vertical bricks is arranged at intervals, and two adjacent rows of vertical bricks are arranged alternately to form an air passage. A layer of refractory bricks 3 is tiled above the vertical bricks, and the gap between the refractory bricks is the air-introduction channel, and the air-induction pipe 4 is arranged below the furnace body to communicate with the induced draft fan. The optimum diameter of the furnace body is 1900-2000mm, and the height is about 1000mm. The carbonization time of each furnace for a 0.5 ton carbonization furnace only needs 3-4 hours.

[0016] Take 2 parts of rice husk, 2 parts of sawdust, 2 parts of wheat straw or straw, 2 parts of coconut shell, and 2 parts of bamboo. The water content of each raw material is not higher than 15%, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com