Automation solar energy biogas fermentation method and device

A biogas fermentation, solar energy technology, applied in biological sludge treatment, sludge treatment, waste fuel and other directions, can solve the problems of scrapping, less gas production, no gas production, etc., and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

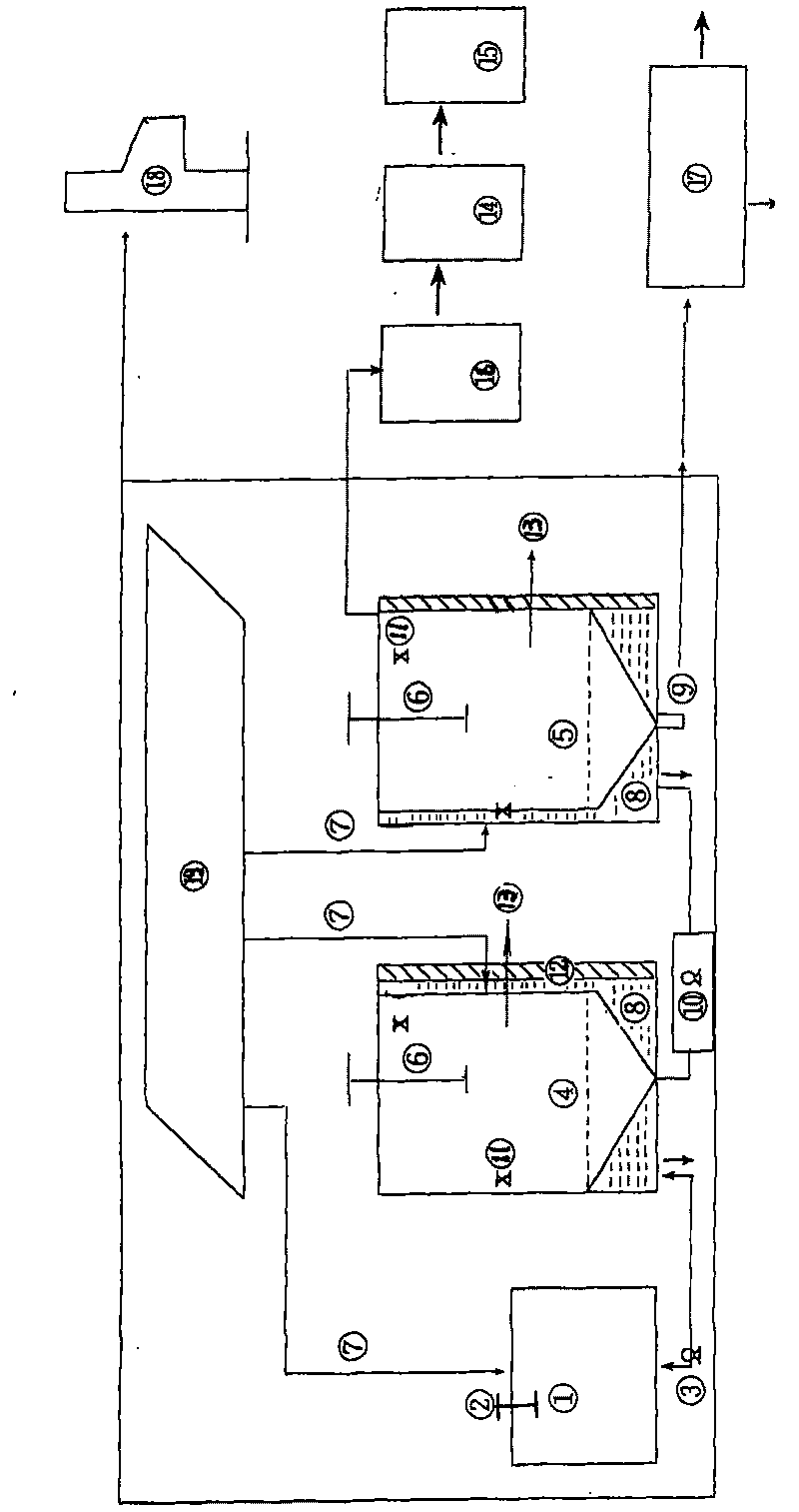

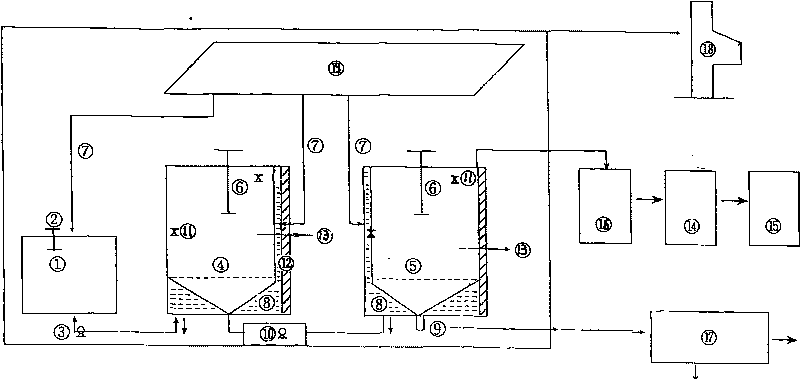

[0027] Concrete steps of the present invention are:

[0028] a, at first the ight soil mixture in the septic tank 1 is sent to the material tank 13 in the hydrolysis acidification treatment tank 4 by the automatic feed delivery pump 3 to carry out hydrolysis and acidification treatment, to reach the fermentation of the ight soil mixture; Stirring by stirrer 2 in pool 1;

[0029] B, the excrement mixture after the hydrolysis and acidification treatment tank 4 is sent into the material tank 13 in the anaerobic digestion tank 5 through the automatic feeding pump 10, and stirred and fermented in the anaerobic digestion tank 5;

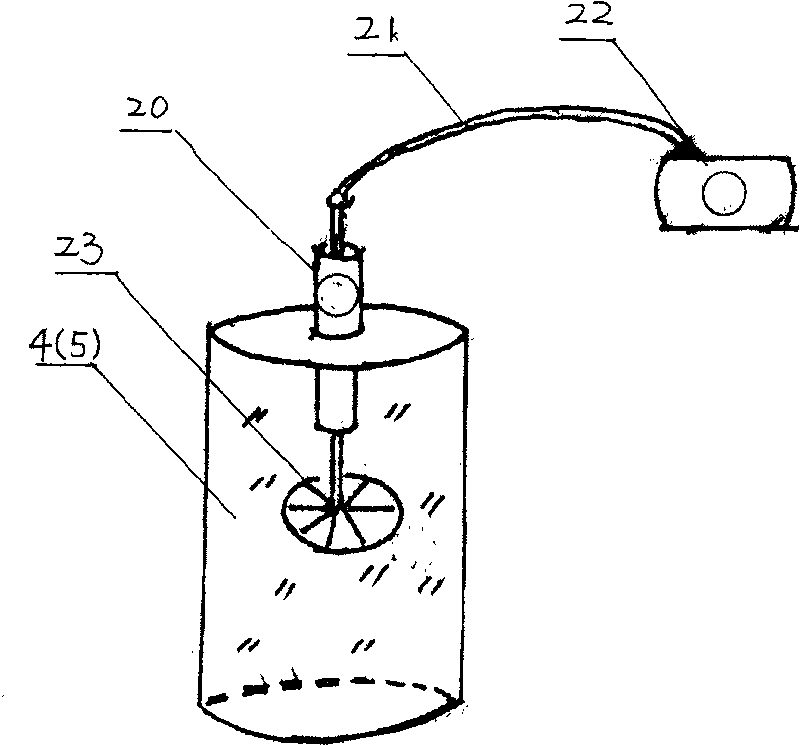

[0030] c, the agitator 6 is installed on the hydrolytic acidification treatment tank 4 and the anaerobic digestion tank 5;

[0031] d, the solar heat collector 19 sends hot water into the water collection interlayer 8 of the hydrolysis acidification treatment tank 4 and the anaerobic digestion tank 5 through the temperature control pump and the solar hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com