Concept for slurry separation and biogas production

A technology of biogas and biogas fermentation, which is used in products, educts, biological sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

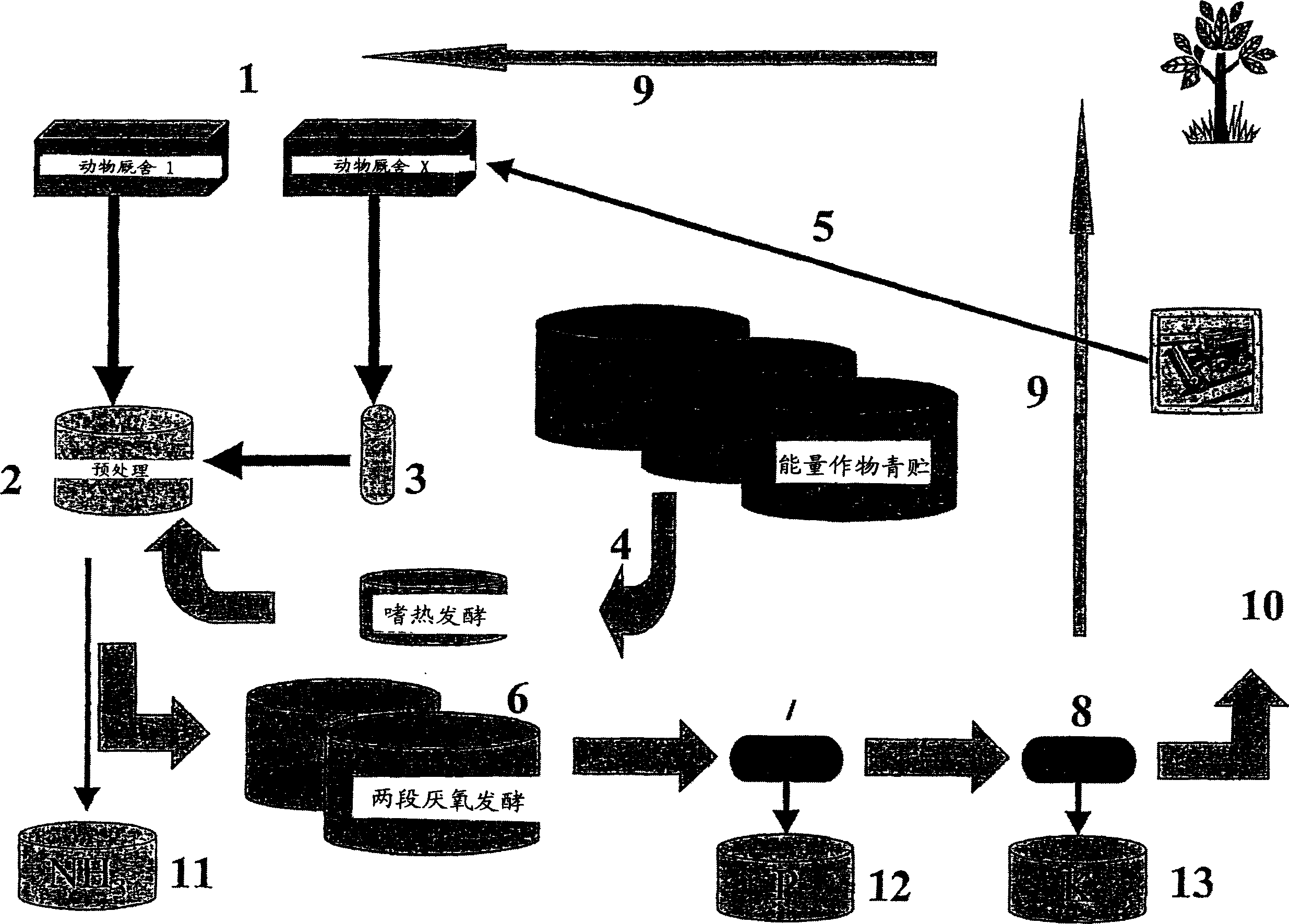

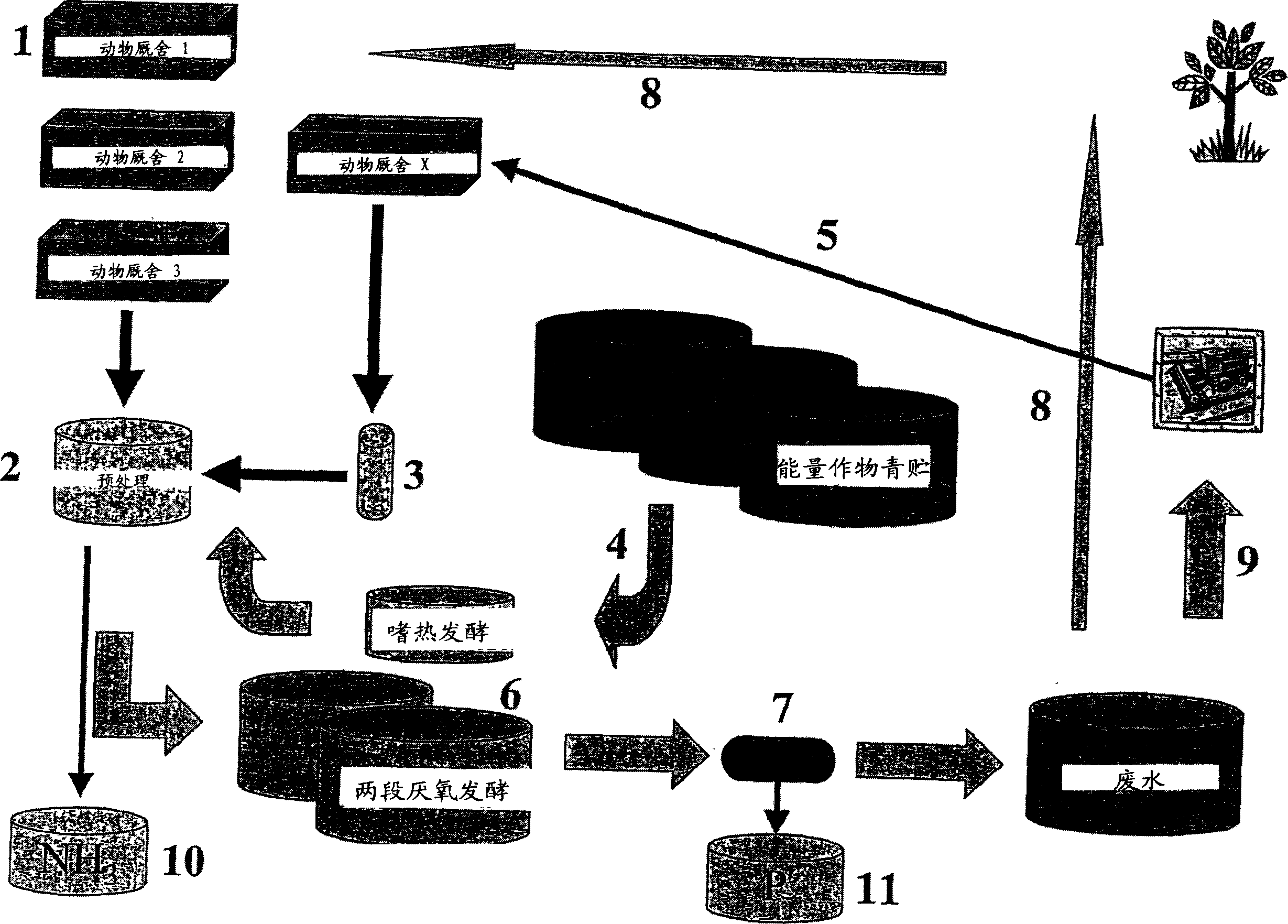

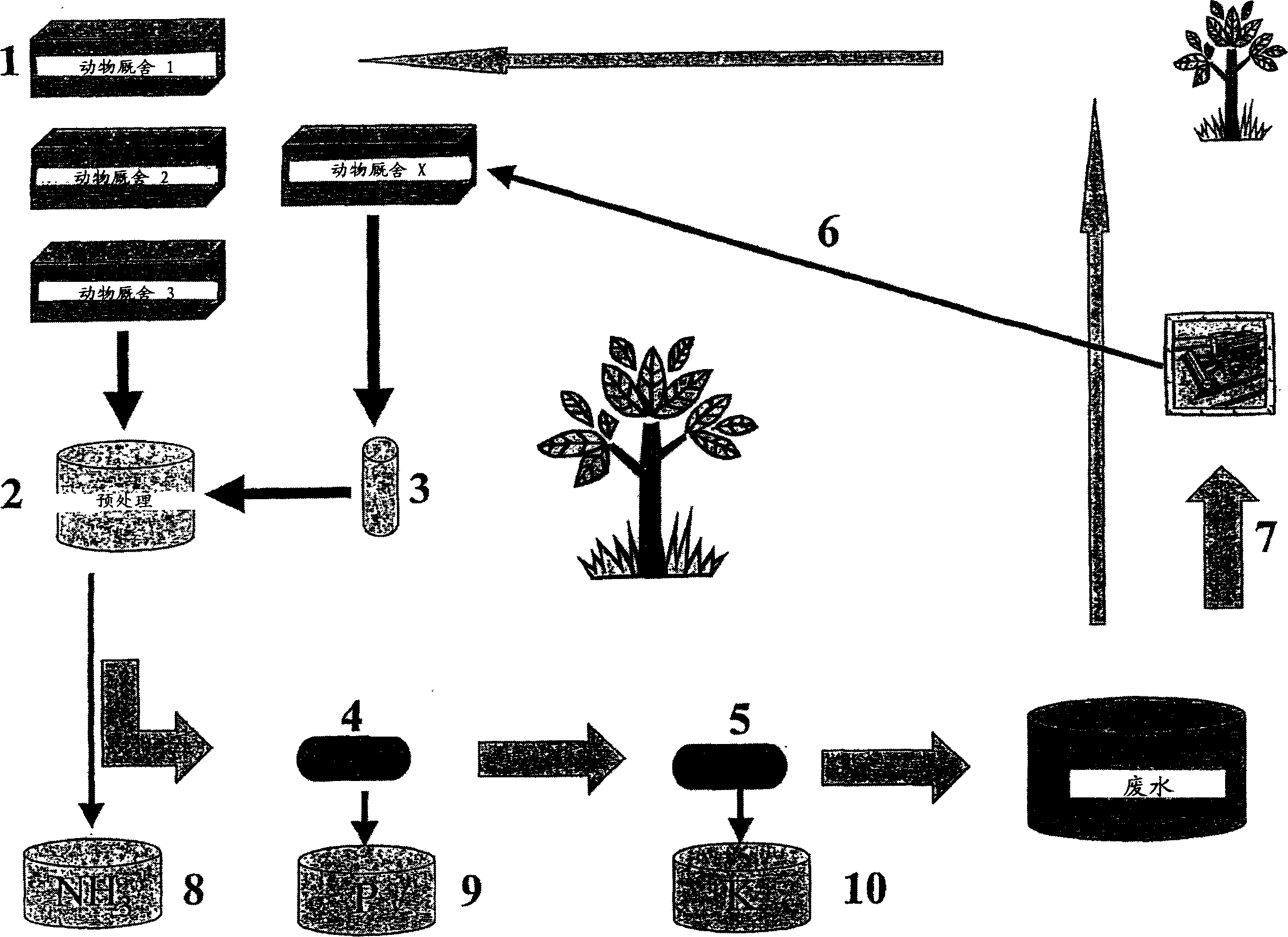

[0195] The invention relates to a number of independent aspects as described below.

[0196] The first aspect (disinfection)

[0197] The first aspect includes a system consisting of a first device, a stable or stall for housing animals including livestock such as pigs and cattle, and / or a second device primarily for stripping ammonia and pretreating substrates. device and / or a third device consisting primarily of an energy device for improving energy production from a substrate.

[0198] The system preferably consists of an animal stable, a stripping tank and a biogas reactor. Other components may include for adding CaO or Ca(OH) to the slurry 2 plants, absorption towers operating on eg sulfuric acid, storage tanks for ammonia concentrate and storage tanks for digested slurries.

[0199] The biogas produced can ideally be used to generate electricity and heat in gas engines and generators, preferably to sell the electricity to the grid, and preferably use the heat to heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com