Plug flow type bioleaching process and apparatus for sludge treatment

A bioleaching and plug-flow technology, applied in the field of environmental engineering, can solve problems such as poor sanitation, easy corruption, and small size, and achieve low investment and operating costs, improved flocculation and dehydration performance, and stable production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Continuous push-flow bioleaching method for treating tannery sludge

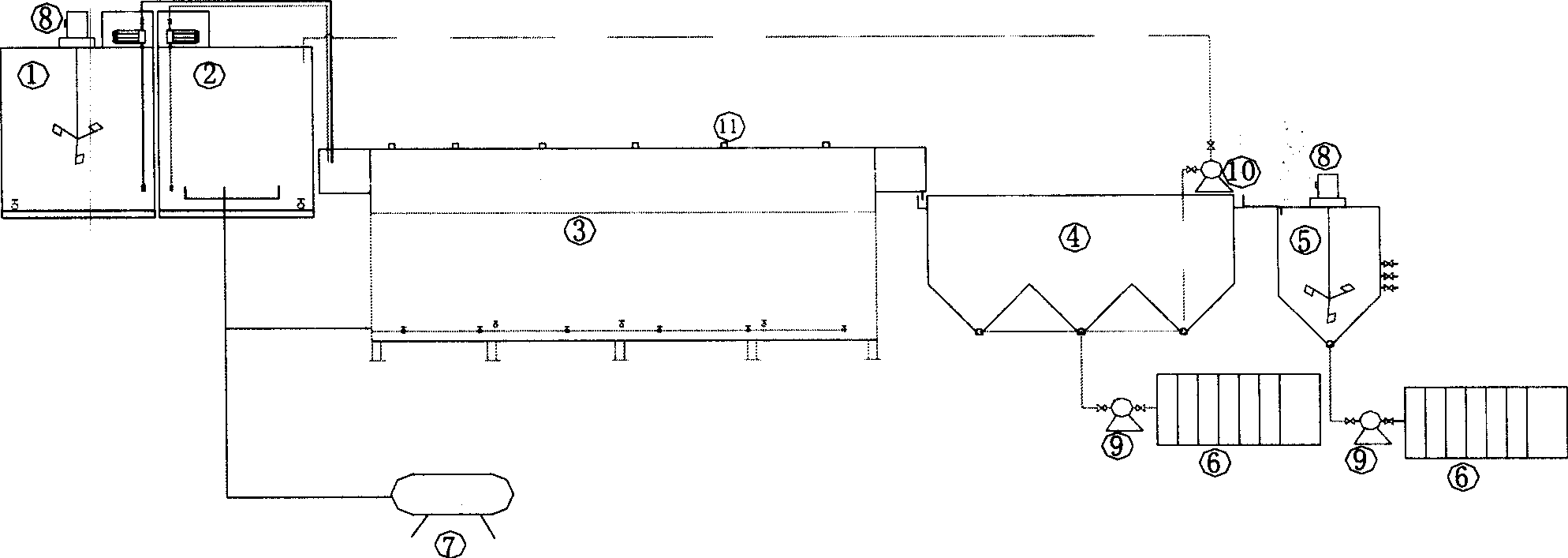

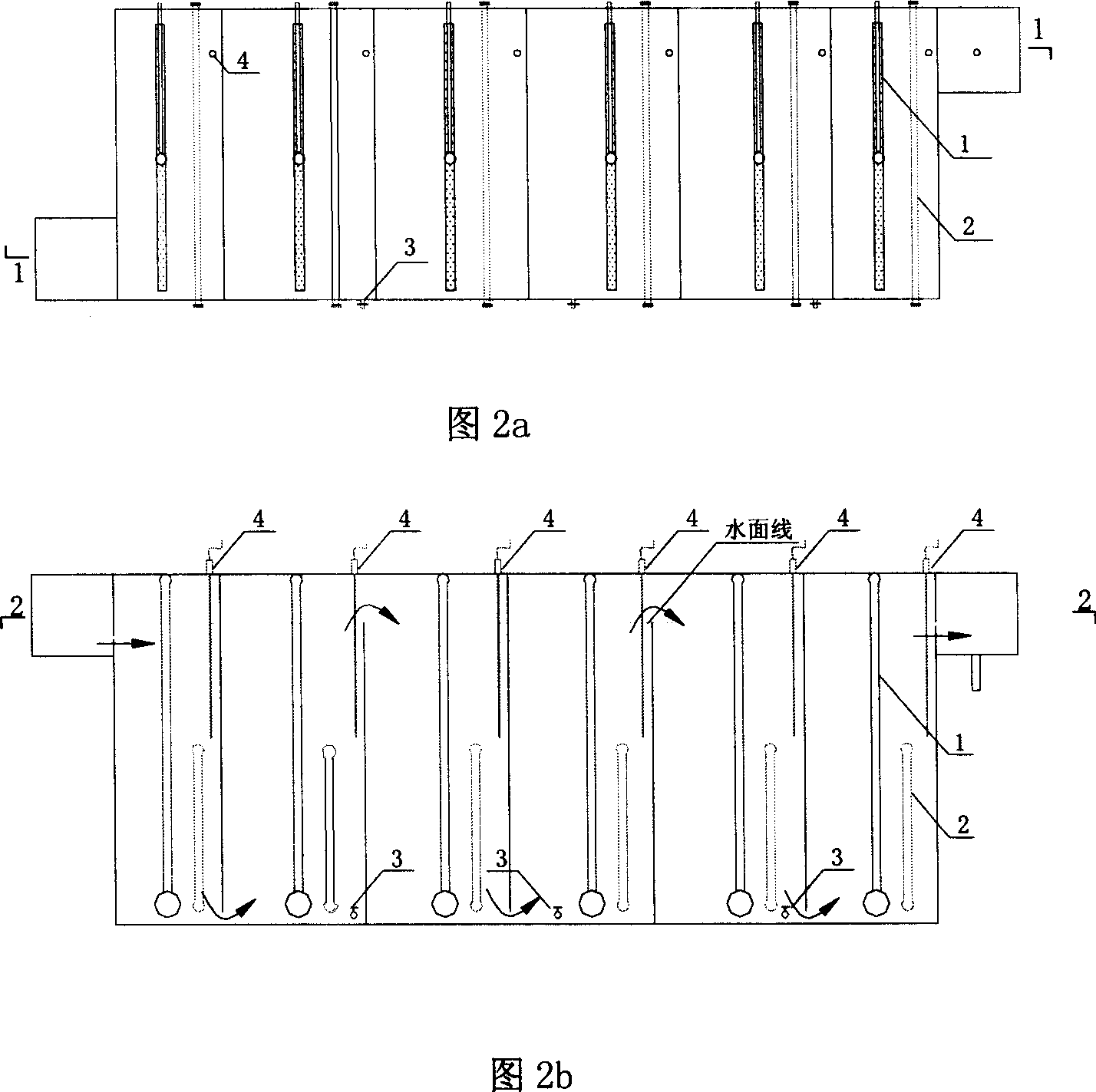

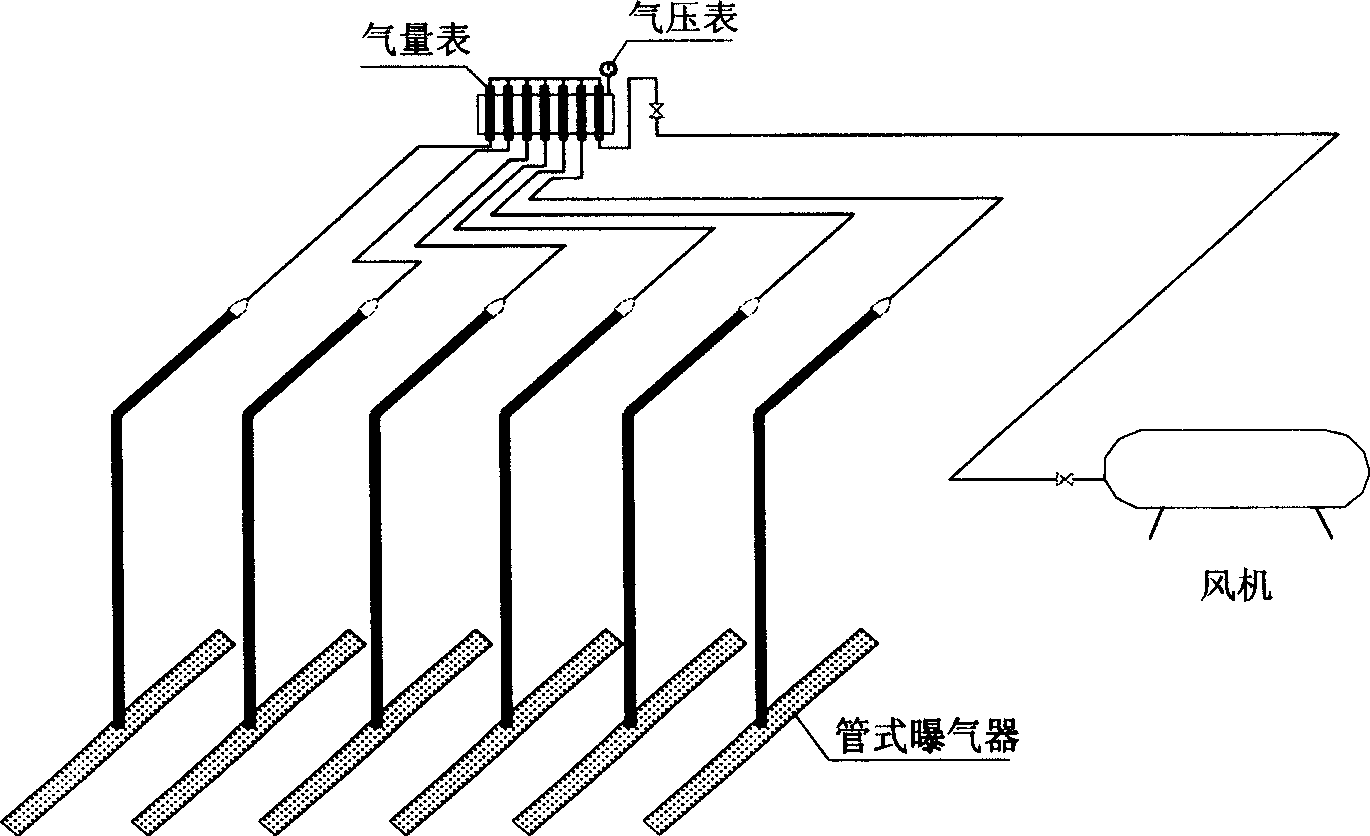

[0031] According to the technique and equipment mentioned in the present invention, a set of continuous plug-flow bioleaching method is designed to process the technological process and equipment of sewage (silt) mud (see attached figure 1 ). In this project, the sewage (silt) sludge adjustment pond is 30m 3 , working volume of plug-flow bioleaching reactor is 100m 3 , advection concentration pool 10m 3 , recovery pool 20m 3 , activation pool 10m 3 , Roots blower power 5.5KW, wind pressure 39kpa, air volume 6m 3 / min; the dehydrator is a box-type filter press dehydrator (model XMG80 / 1000-U), with a filtration area of 80m 2 .

[0032] The organic waste for treatment is tannery sludge with a solid content of 2%-4% and a chromium content of 18000-31000mg / kg dry sludge. In the bioleach reactor, raw sludge is 3 / d amount into the reactor, press 5-10M at the same time 3 / d into the rec...

Embodiment 2

[0034] Example 2 Continuous push-flow bioleaching method for treating municipal sludge

[0035] Process flow and equipment facility are identical with embodiment 1. The organic waste for treatment is sludge from urban sewage treatment plants, the solid content is about 2-3%, and the heavy metal Cu content reaches 4500mg / kg dry mud, Zn2800mg / kg, Ni525mg / kg, Cd25mg / kg, Cr625mg / kg. In the bioleach reactor, raw sludge is 3 / d amount into the reactor, press 5-10M at the same time 3 / d into the reflux activated sludge after bioleaching, the sludge residence time in the reactor is 2-3 days, the pH of the bioleaching sludge at the sludge outlet drops below 2, and most of the heavy metals in the sludge are dissolved. After the sludge treated by bioleaching is further concentrated by gravity (with a water content of 93%), it is dehydrated with a chamber filter press (without adding any flocculant) to a water content of less than 65%. After this treatment, the removal rate of the abov...

Embodiment 3

[0036] Example 3 Treatment of livestock and poultry manure by continuous plug-flow bioleaching

[0037] Process flow and equipment facility are identical with embodiment 1. The organic waste for treatment is flushing livestock and poultry manure from large-scale pig farms, with a solid content of about 7-8%, heavy metal Cu content of 800mg / kg dry mud, Zn 544mg / kg, Cr 85mg / kg. For the convenience of treatment, before entering the bioleach reactor, the original flushing livestock and poultry manure is diluted in the adjustment tank to a solid content of less than 4%, and then press 10M 3 / d amount into the reactor, press 3-5M at the same time 3 / d into the reflux activated sludge after bioleaching treatment, the residence time of the livestock and poultry manure sludge in the reactor is 2 days, the pH of the bioleached manure at the sludge outlet drops below 3, and most of the heavy metals in the livestock and poultry manure Dissolution. After the manure treated by bioleachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com