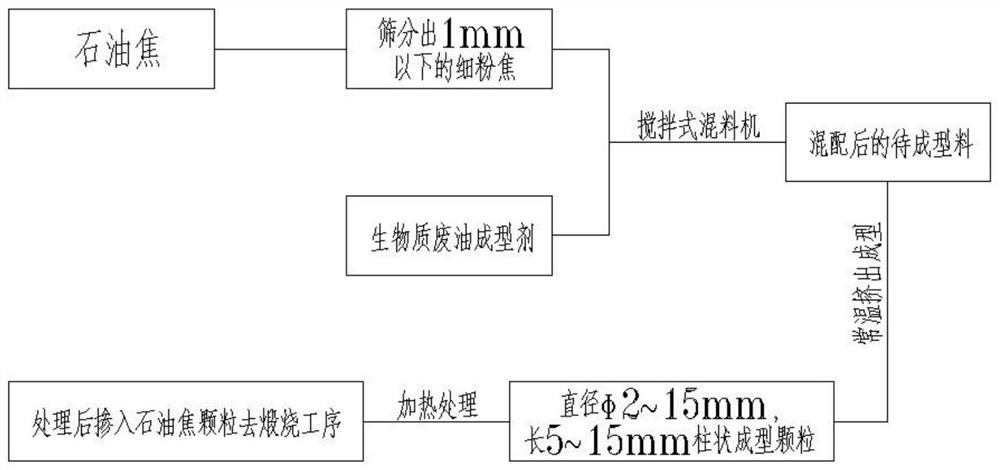

Petroleum coke fine powder coke forming process

A molding process and technology of petroleum coke, which is applied in the preparation/purification of carbon, etc., can solve the problems of increasing the amount of fine powder coke and biomass waste oil, and achieve the problem of solving subsequent processing problems, reducing time consumption and increasing the actual yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

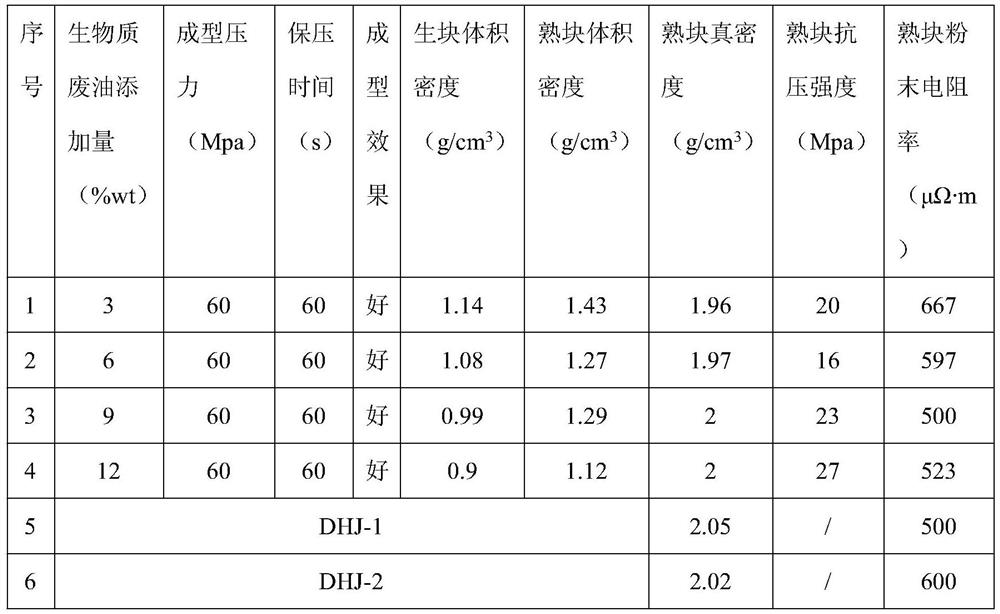

Embodiment 1

[0025] (1) Weigh 100g of petroleum coke fine powder coke (particle size<1mm) and 3.1g of molding agent (biomass waste oil), and fully mix with a stirring mixer at normal temperature to obtain the material to be molded;

[0026] (2) Place the material to be molded in a twin-screw extrusion granulator, and obtain a columnar pellet with a diameter of Φ2 mm and a length of 5 mm under an extrusion pressure of 10 MPa;

[0027] (3) Put the shaped pellets into a sintering furnace and heat them up to 200°C at a heating rate of 20°C / min, keep the temperature for 1 hour, and cool down naturally to obtain finished pellets.

Embodiment 2

[0029] (1) Weigh 100g of petroleum coke fine powder coke (particle size<1mm) and 13.5g of molding agent (biomass waste oil), fully mix with a stirring mixer at normal temperature, and obtain the material to be molded;

[0030] (2) Place the material to be molded in a twin-screw extrusion granulator, and obtain a diameter of Φ15mm and a columnar pellet with a length of 15mm under an extrusion pressure of 30MPa;

[0031] (3) Put the shaped pellets into a sintering furnace and heat them up to 300°C at a heating rate of 30°C / min, keep them warm for 0.5h, and cool down naturally to obtain finished pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com