Method for treatment of waste emulsion

A waste emulsion and treatment method technology, applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of high operating cost and increased investment, and achieve low operating cost, small footprint, Obvious operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

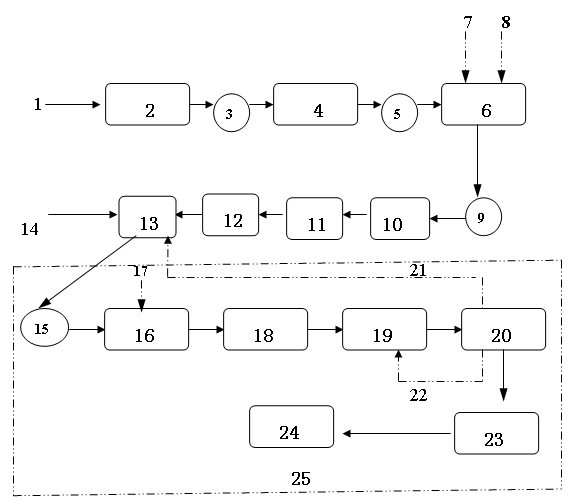

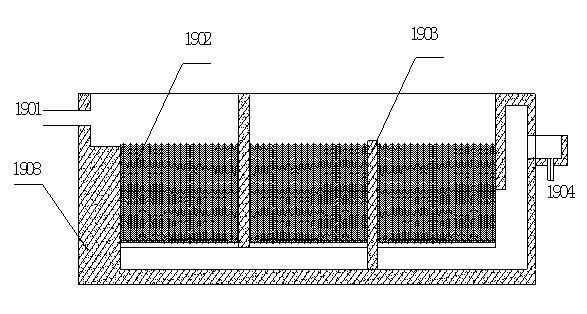

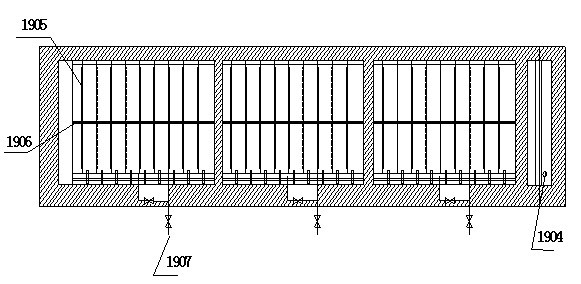

Method used

Image

Examples

Embodiment 1

[0064] The waste emulsion from a steel pipe processing plant contains a large amount of iron filings, surfactants, and 1.5% oil, and its COD value is 80,000-100,000 mg / L. The method of the present invention and The device treats the waste emulsion, adding demulsifier CaCl 2 and Al 2 (SO 4 ) 3 The dosage is 4kg / m 3 and 5kg / m 3 , the temperature is controlled at 70-80°C, stirred for 2 hours, demulsified and settled for 15 hours, and the treatment capacity is 10 tons. After being treated by the sewage treatment station, the COD value in the effluent quality is 40-100mg / L, and the petroleum content is 1-5mg. / L, fully meet the "National Sewage Comprehensive Discharge Standard" GB8978-1996 Class I standard, the waste oil collected during disposal is regenerated and refined to produce the patented product - protective grease.

Embodiment 2

[0066] The waste emulsion from a mechanical processing factory contains 5% waste oil, surfactant and water, and its COD value is 40000-80000 mg / L. The method and device of the present invention are used to process the waste emulsion Treatment, add demulsifier CaCl 2 and Al 2 (SO 4 ) 3 The dosage is 3kg / m 3 and 4kg / m 3 , the temperature is controlled at 70-80°C, stirred for 2 hours, demulsified and settled for 15 hours, and the treatment capacity is 10 tons. After being treated by the sewage treatment station, the COD value in the effluent quality is 40-100mg / L, and the petroleum content is 1-5mg. / L, fully meet the "National Sewage Comprehensive Discharge Standard" GB8978-1996 Class I standard, the waste oil collected during disposal is regenerated and refined to produce the patented product - protective grease.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com