Acid and alkali free quick regeneration method for waste oil

A fast, acid-base technology, applied in the multi-stage series refining process treatment, lubricating composition, etc., can solve the problems of poor working environment for waste oil regeneration, long time for waste oil regeneration, and high labor intensity of workers, etc. No acid, alkali and sulfur dioxide odor, low cost and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

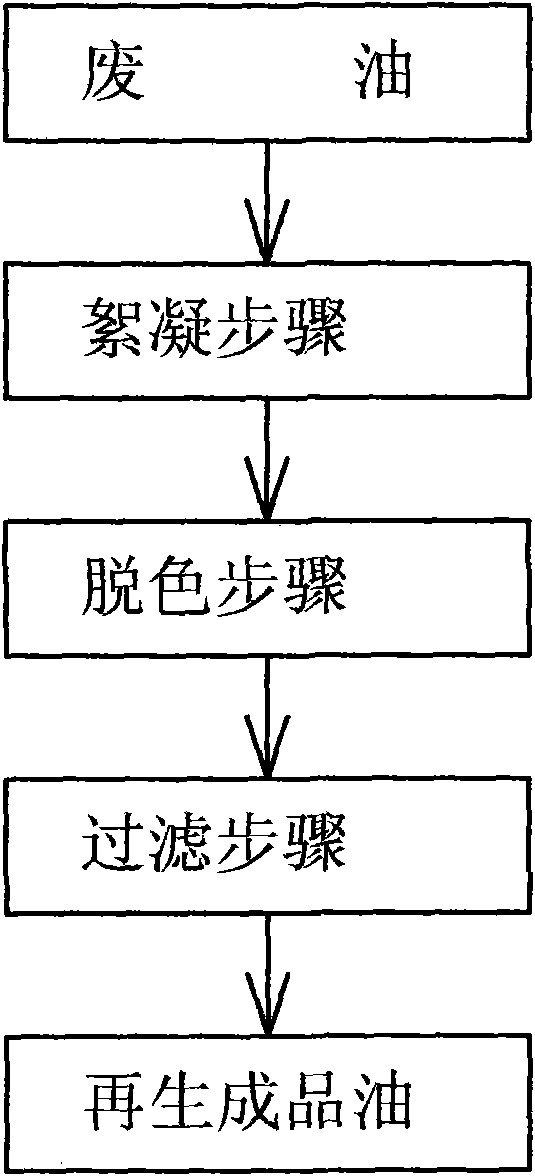

[0031] refer to figure 1 , Figure 4 , an acid-base rapid regeneration method for waste oil, comprising the following steps:

[0032] a), flocculation step

[0033]Will waste oil be joined in the reaction kettle 7 from oil inlet 12, add the activated clay of 1.5% of oil weight and the cationic polyacrylamide of 0.5% of oil weight, stir for 25 minutes, stop stirring, stand and settle for 120 minutes, from The bottom of reactor 7 gets rid of oxidation residue and sediment;

[0034] b), decolorization step

[0035] The oil after the flocculation is in the reaction kettle 7, adds the active clay of oil weight 8%, stirs 20 minutes;

[0036] c), filtering step

[0037] The decolorized oil is sucked into the filter 8 by the gear pump 10 and filtered to obtain the regenerated refined oil.

[0038] During the regeneration process of waste oil, the waste oil flow line is: oil inlet 12—reaction kettle 7—gear pump 10—filter 8—oil outlet 9. As long as the waste fuel oil is liquid, t...

Embodiment 2

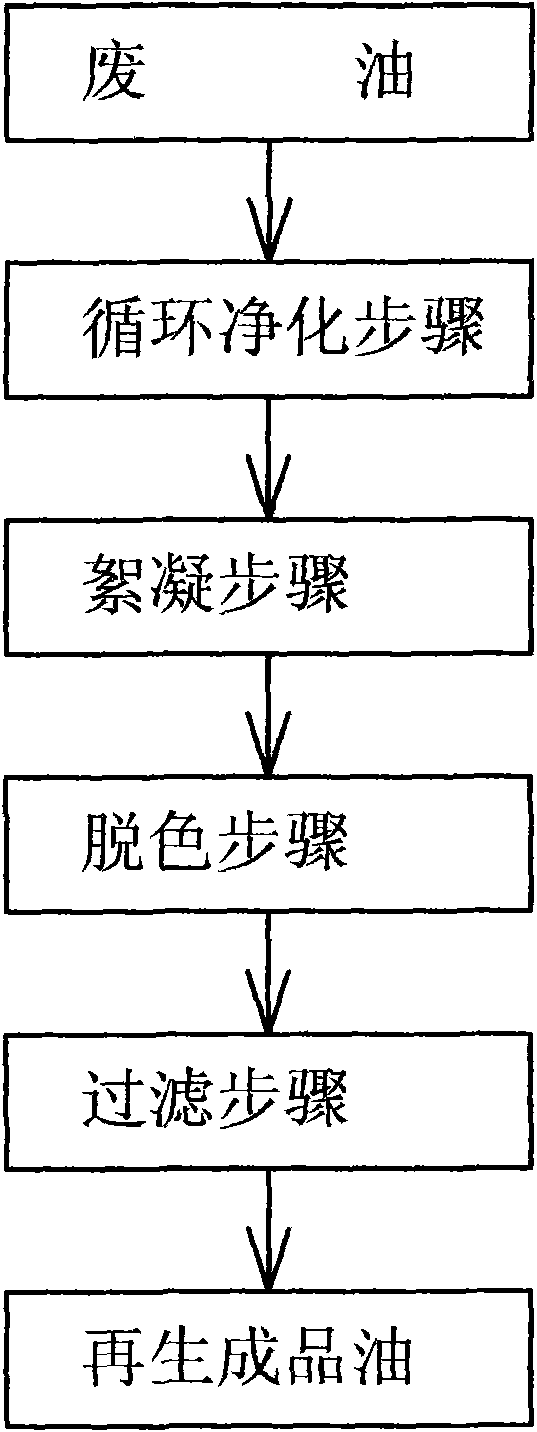

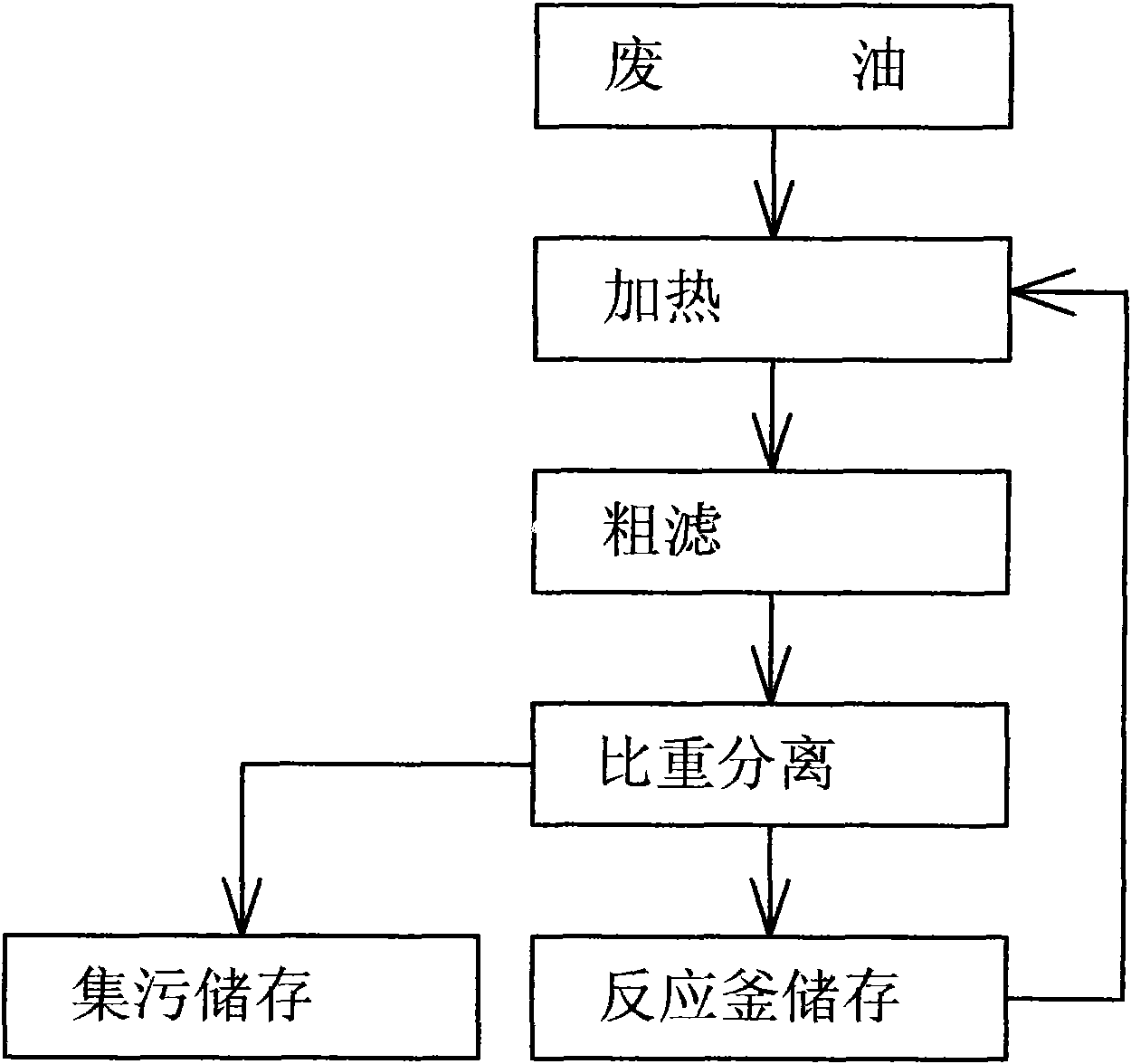

[0041] refer to figure 2 , image 3 , Figure 4 , an acid-base rapid regeneration method for waste oil, comprising the following steps:

[0042] In the cycle purification step, firstly, waste lubricating oil is added to the heater 1 from the oil inlet 12 and heated to 95±2°C; the heated waste oil is transferred to the coarse filter 6 for coarse filtration; The oil is transferred to the specific gravity separation device 13 for decompression separation, and the light oil and water in the head are extracted by the vacuum pump 4 to the sewage collection device 3 for condensation storage, and the oil after the specific gravity separation is stored in the reactor 7; When the amount of oil in the reactor 7 is close to 70% of the volume ratio of the reactor 7, the oil inlet 12 is closed, and then the oil outlet valve at the bottom of the reactor 7 is opened, and the oil in the reactor 7 is input into the heater 1 for circulation and purification. Cycle purification at least twice...

Embodiment 3

[0050] refer to figure 2 , image 3 , Figure 4 , an acid-base rapid regeneration method for waste oil, when the waste oil is a mixed oil of waste lubricating oil and waste fuel oil, it comprises the following steps:

[0051] Circulation purification step, first add the waste oil to the heater 1 and heat it to 30±2°C; transfer the heated waste oil to the coarse filter 6 for coarse filtration; then transfer the coarse filtered oil to the specific gravity separation device In 13, decompression separation is carried out, and the light oil and water in the head are pumped by the vacuum pump to the sewage collection device 3 for condensation storage, and the oil after the specific gravity separation is stored in the reactor 7; the amount of oil in the reactor 7 is close to the reaction When the volume ratio of the kettle 7 is 70%, close the oil inlet 12, then open the oil outlet valve at the bottom of the reactor 7, and input the oil in the reactor 7 into the heater 1, and perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com