Technical method for preparing biodiesel using reactive separation process coupling technique

A technology of biodiesel and separation process, which is applied in the field of chemical technology to avoid the problem of subsequent treatment of catalysts and improve the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

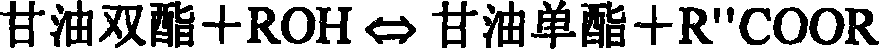

Problems solved by technology

Method used

Image

Examples

Embodiment 1

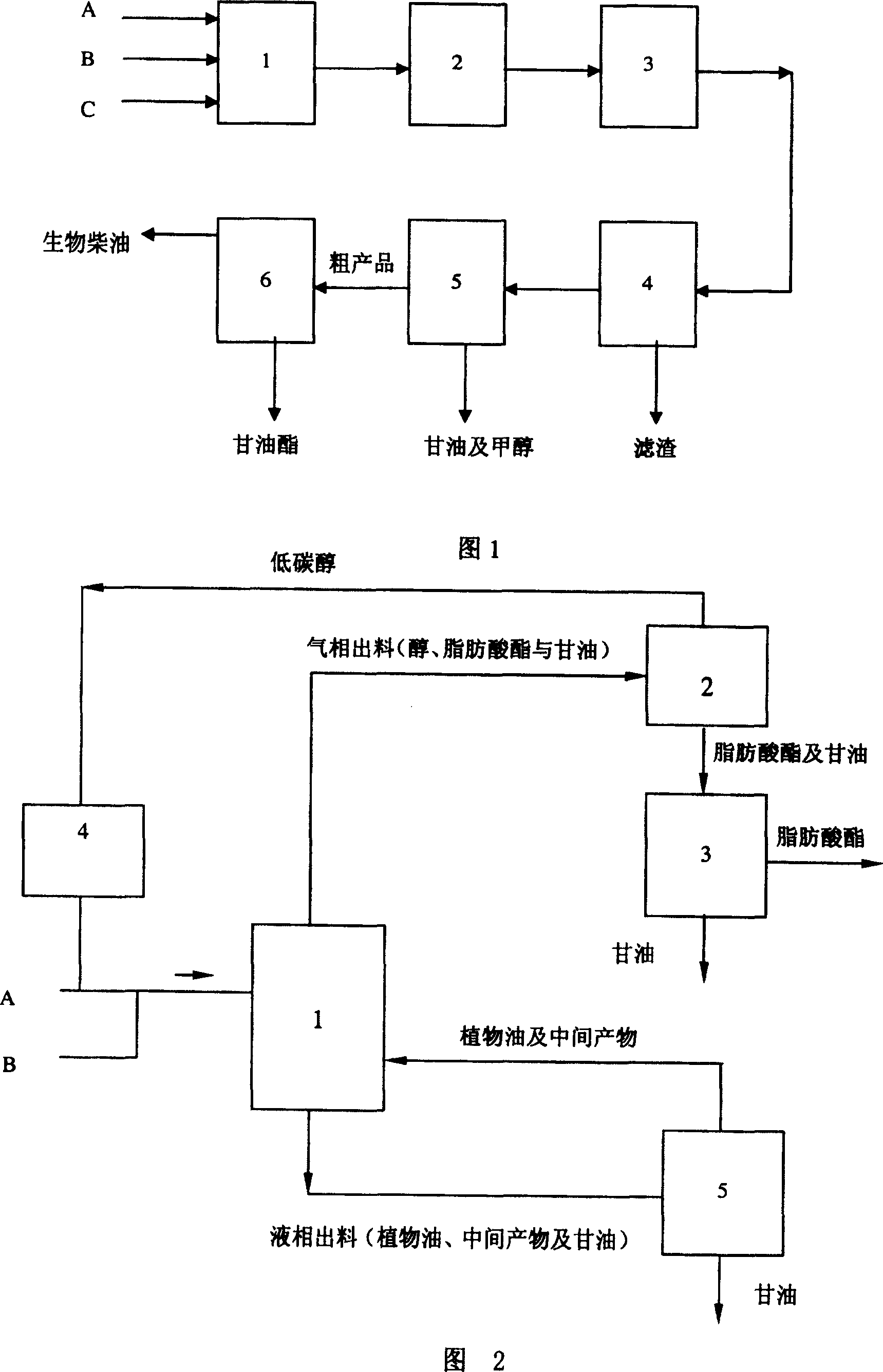

[0038] Example 1 Method for preparing biodiesel from methanol and cottonseed oil using reaction separation process coupling technology

[0039] (1) The reaction between the raw material low-carbon alcohol and cottonseed oil;

[0040] The raw material low-carbon alcohol (methanol) and cottonseed oil at a molar ratio of 6:1 are fed into the reactor 1 through a pump, and the reaction is carried out under the action of a catalyst and maintained at a temperature of 230°C. At this temperature, low-boiling methanol circulates at a space velocity of 0.6L / (hr*gcal.) and is discharged as a gas through the gas phase outlet; the space velocity of the feed oil is 0.025L / (hr*gcal.);

[0041] (2) Separate the product obtained in the first step reaction;

[0042] While the methanol is circulating in a large amount, the product biodiesel and glycerin are taken out of the reactor 1 and enter the distillation tower 2

[0043] The glycerin and mixed oil in the reactor 1 are discharged from the bottom...

Embodiment 2

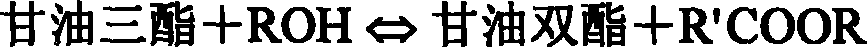

[0049] Example 2 Method for preparing biodiesel by coupling technology of reaction separation process with low-carbon alcohol and animal fat

[0050] (1) Reaction of raw material low-carbon alcohol and animal fat

[0051] According to the molar ratio of animal oil to low-carbon alcohol (ethanol) of 3:1, the catalyst and raw material animal fat and low-carbon alcohol (ethanol) are added to the reactor 1, and the amount of the catalyst is 1wt% of the raw material fat in the reactor; The temperature is maintained at 170°C; the space velocity of the circulating lower alcohol is 0.5L / (hr*gcal.); the space velocity of the raw oil is 0.02L / (hr*gcal.); the reaction is carried out;

[0052] (2) Separate the products obtained in the first step of the reaction

[0053] Separate the products of the first step transesterification reaction to separate biodiesel and glycerin from the reaction system;

[0054] Keep the reaction temperature at 170°C, make the low-boiling low-carbon alcohol flow ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com