Detection imaging method and apparatus of strip surface flaw

A strip surface and defect detection technology, which is applied in the direction of optical detection of defects/defects, can solve problems such as poor real-time performance, complex dual-field imaging structure, high cost, and missed detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

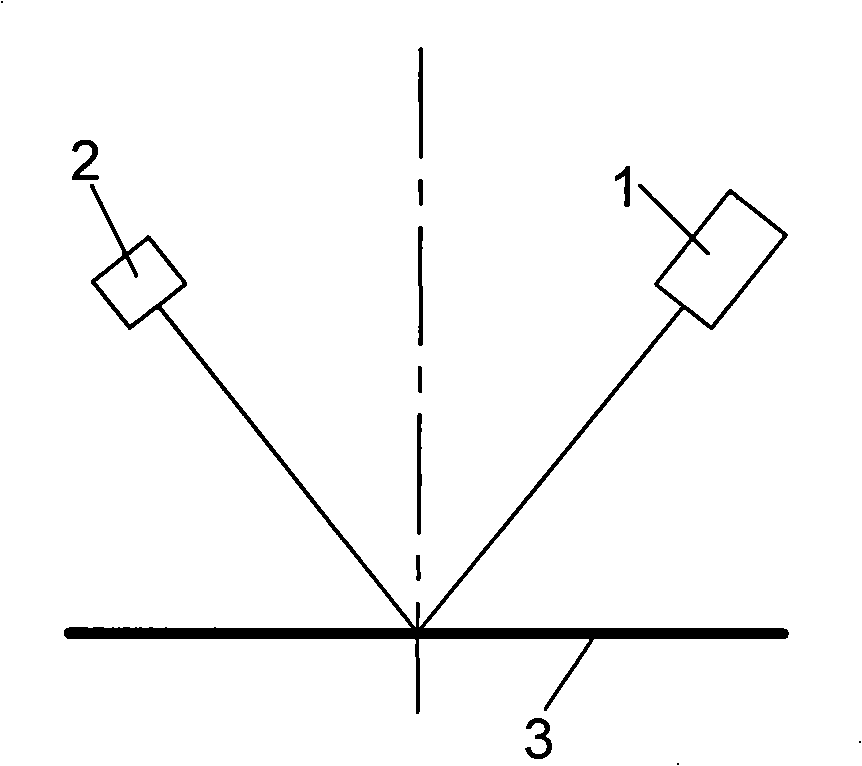

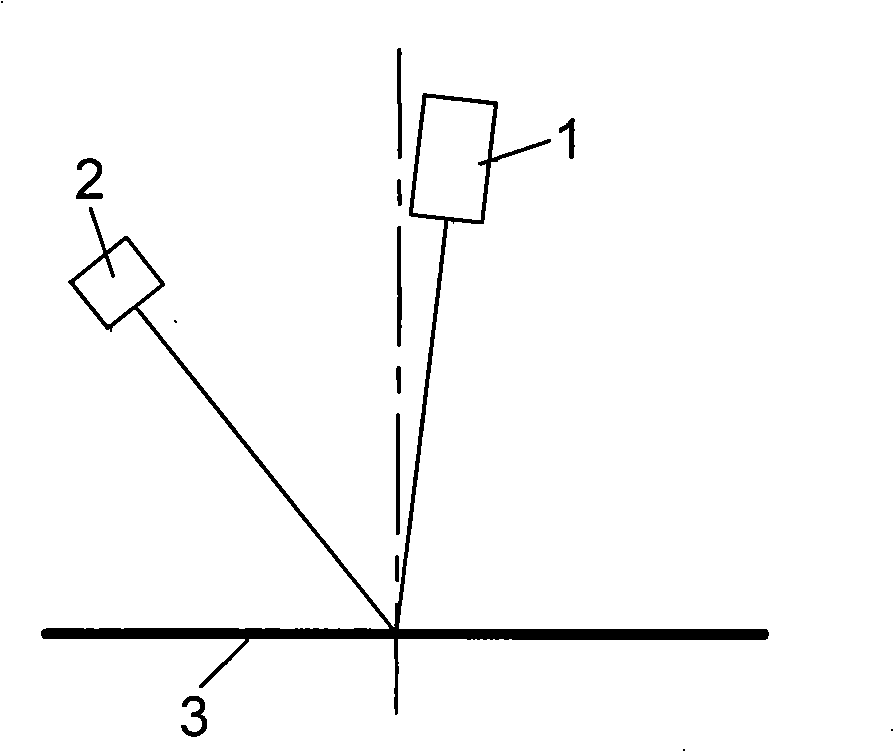

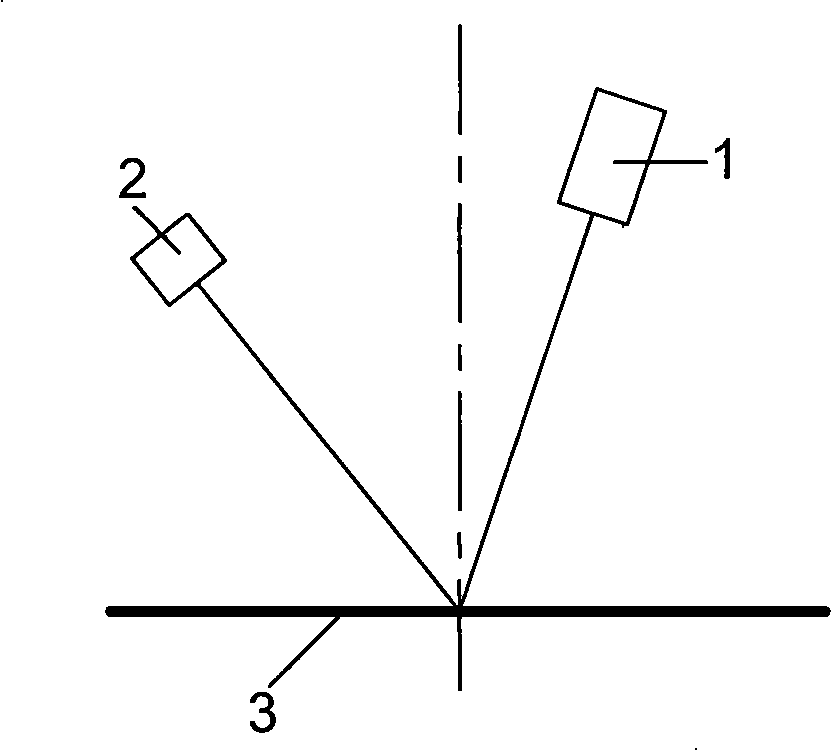

[0037] see Image 6 As shown, the specific steps of the strip surface defect detection and imaging method of the present invention are: first set up a synchronous signal generating unit and generate a synchronous signal, and synchronously control the switching unit and the camera unit; then set up a switching unit, use the switching unit The following two light sources are switched and controlled; then the two light sources are used to alternately illuminate the surface of the strip, and respectively form a single-field imaging with the camera unit, thereby forming the scanning imaging of the strip surface by the camera unit. Among them, the synchronization signal can be directly generated by the synchronization signal generator, or depending on the specific situation, first use the synchronization signal generator to send the original synchronization signal; then use the filter to filter the original synchronization signal; The signal is shaped; finally, the frequency modulat...

Embodiment 2

[0039] see Figure 7As shown, the strip surface defect detection imaging device 10 of the present invention includes a synchronous signal generating unit 11, which is connected to the switching unit 12 and the camera unit 13 respectively, and the synchronous signal generating unit 11 sends a synchronous signal and controls the switching unit 12 and the synchronization of the camera unit 13; the switching unit 12 is connected to two light sources 14a, 14b respectively, and controls the switching of the two light sources 14a, 14b; the two light sources 14a, 14b alternately carry out lighting, and form a single-field imaging with the imaging unit 13, so that the imaging unit 13 can scan and image the strip surface 3. As shown in FIG. 8 , the synchronization signal generating unit 11 is a single synchronization signal generator. When a larger synchronous signal is needed, the synchronous signal generating unit can also be made to include a synchronous signal generator, a filter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com