A method for flue gas carbon fixation seawater decalcification

A flue gas and seawater technology, applied in seawater treatment, separation methods, water softening, etc., can solve the problem of high cost of decalcification, and achieve the effect of strong operability, reduced treatment cost, and favorable industrialization implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

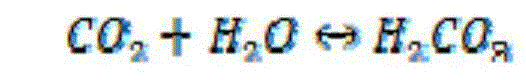

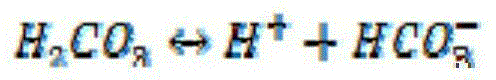

Method used

Image

Examples

Embodiment 1

[0030] Set the calcium content to 0.87kg / m 3 The brine is introduced into the pre-mixing tank by the pump, and the alkali source is added to the brine. The type of alkali source is white mud produced after decalcification and magnesium pretreatment in the brine refining process of the soda plant, and the content of magnesium hydroxide in the white mud is 10. %, the mass content of calcium carbonate is 50%, the mass content of calcium sulfate is 20%, and the mass content of calcium chloride is 10%. And the molar ratio of the total magnesium content in the added alkali source to the calcium content in the total brine is 3:1, stir for 20 minutes to fully mix the brine and the alkali source. Use the pump to make the brine mixed with the alkali source 10m 3 The flow rate of / h enters the decalcification tank, and at the same time, the flue gas is introduced into the decalcification tank through the aeration head through the Roots blower, wherein the carbon dioxide content of the c...

Embodiment 2

[0031] Set the calcium content to 1.20kg / m 3 The brine is introduced into the pre-mixing tank by the pump, and the alkali source is added to the brine. The type of alkali source is white mud produced after decalcification and magnesium pretreatment in the brine refining process of the soda plant. The content of magnesium hydroxide in the white mud is 15 %, the mass content of calcium carbonate is 40%, the mass content of calcium sulfate is 15%, and the mass content of calcium chloride is 14%. And the molar ratio of the total magnesium content in the added alkali source to the calcium content in the total brine is 4:1, stir for 30 minutes, so that the brine and the alkali source are fully mixed. Use the pump to make the brine mixed with alkali source 20m 3 / h flow into the decalcification tank, at the same time, the flue gas is introduced into the decalcification tank through the aeration head through the Roots blower, wherein the carbon dioxide volume content of carbon dioxid...

Embodiment 3

[0033] Set the calcium content to 0.89kg / m 3 The concentrated seawater is introduced into the pre-mixing tank by the pump, and the alkali source is added to the brine. The type of alkali source is white mud produced after decalcification and magnesium pretreatment in the brine refining process of the soda plant, and the content of magnesium hydroxide in the white mud is 12%, the mass content of calcium carbonate is 55%, the mass content of calcium sulfate is 3%, and the mass content of calcium chloride is 12%. And the molar ratio of the total magnesium content in the added alkali source to the calcium content in the total brine is 2.5:1, and stirred for 30 minutes to fully mix the brine and the alkali source. Use the pump to make the brine mixed with alkali source 15m 3 / h flow into the decalcification tank, at the same time, the flue gas is introduced into the decalcification tank through the aeration head through the Roots blower, wherein the carbon dioxide volume content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com