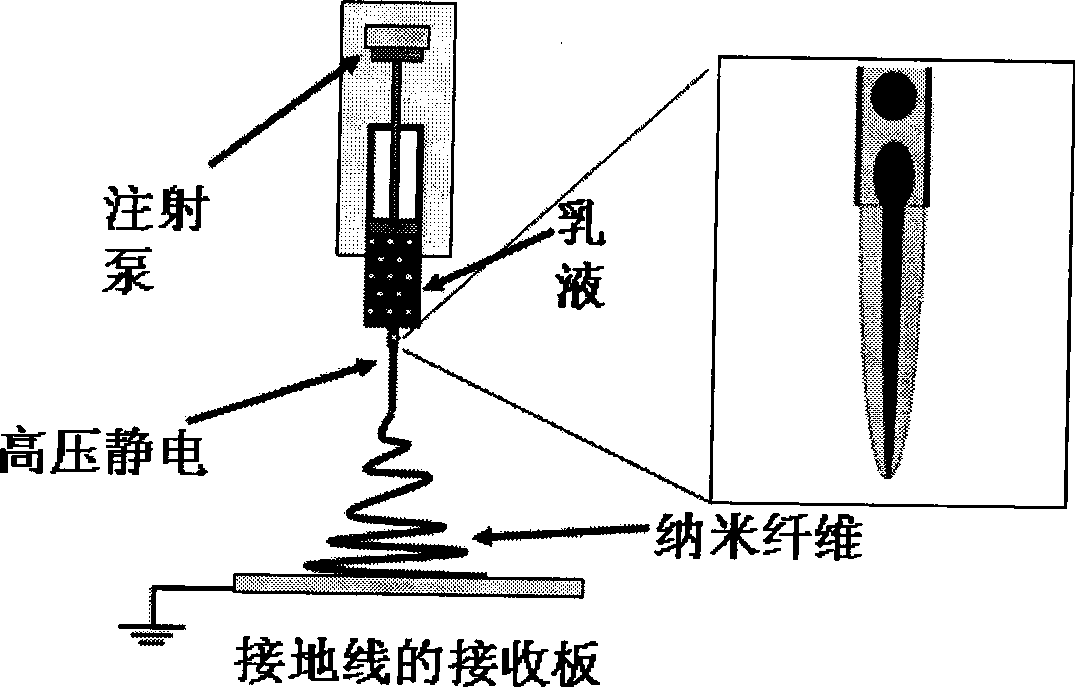

Method for producing shell-core structure medicament nano-fibre with emulsion electrostatic spinning technology

An electrospinning technology and nanofiber technology are applied in the field of preparing shell-core structure drug nanofibers by emulsion electrospinning technology, and achieve the effects of good economic benefits, mild reaction conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 0.5g BSA with an electronic balance, and dissolve it in 10mL ultrapure water, stir and oscillate to dissolve completely to obtain an aqueous phase solution;

[0030] Weigh 0.8g polylactic acid-caprolactone P(LLA-CL)[75:25], 0.05g rhodamine B, and 0.05g SPAN-80 respectively with an electronic balance, dissolve them in 10mL of dichloromethane, stir and oscillate until dissolved Completely, an oil phase solution is obtained;

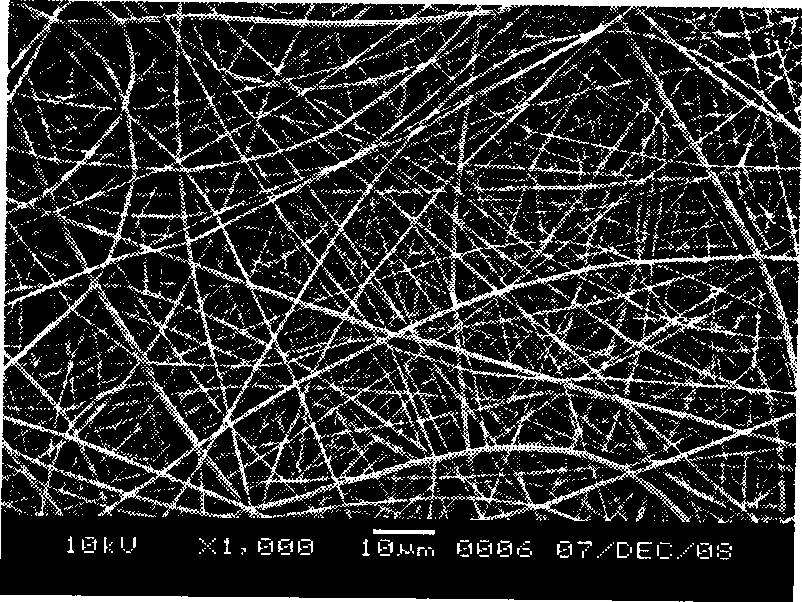

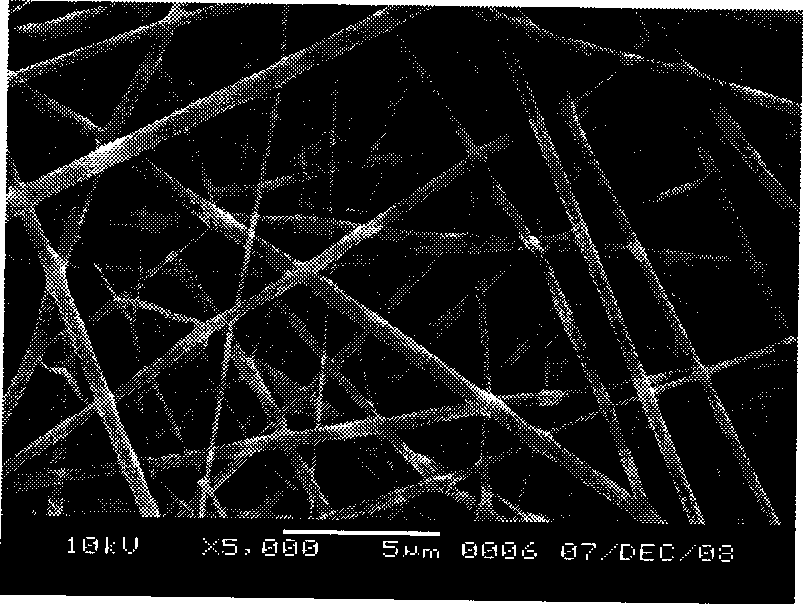

[0031] Under the condition of stirring, 0.5 mL of aqueous solution was added dropwise to the oil phase solution, and the stirring was continued until a uniform emulsion was obtained. Electrospinning was performed on the obtained emulsion, the applied voltage was 20kv, the receiving distance was 15cm, the spinning speed was 1.0mL / h, and the diameter of the spinneret was 0.9mm. The diameter of the obtained nanofiber is between 200nm and 1500nm.

Embodiment 2

[0033] Weigh 0.3g tetracycline hydrochloride with an electronic balance, dissolve it in 10mL ultrapure water, stir and oscillate to dissolve completely to obtain an aqueous phase solution;

[0034] Weigh 0.8g of polylactic acid-caprolactone P(LLA-CL) [50:50], 0.3g of griseofulvin, and 0.05g of sodium dodecylsulfonate with an electronic balance, and dissolve them in 10mL of chloroform , stirred and oscillated until completely dissolved to obtain an oil phase solution;

[0035] Under the condition of stirring, 0.5 mL of aqueous solution was added dropwise to the oil phase solution, and the stirring was continued until a uniform emulsion was obtained. Electrospinning was performed on the obtained emulsion, the applied voltage was 20kv, the receiving distance was 15cm, the spinning speed was 1.0mL / h, and the diameter of the spinneret was 0.9mm. The diameter of the obtained nanofiber is between 300nm and 1000nm.

Embodiment 3

[0037] Weigh 0.5g doxorubicin with an electronic balance, dissolve it in 10mL ultrapure water, stir and oscillate to dissolve completely to obtain an aqueous phase solution;

[0038] Weigh 0.8g polylactic acid PLLA, 0.05g paclitaxel, and 0.05g glycerol monooleate respectively with an electronic balance, dissolve them in 10mL of chloroform, stir and oscillate until completely dissolved, and obtain an oil phase solution;

[0039]Under the condition of stirring, 0.5 mL of aqueous solution was added dropwise to the oil phase solution, and the stirring was continued until a uniform emulsion was obtained. Electrospinning was performed on the obtained emulsion, the applied voltage was 20kv, the receiving distance was 15cm, the spinning speed was 1.0mL / h, and the diameter of the spinneret was 0.9mm. The diameter of the obtained nanofiber is between 200nm and 1200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com