Rock joint direct shear test system suitable for CT three-dimensional real-time scanning

A rock joint and shear test technology, which is applied in the field of geotechnical engineering, can solve problems such as poor stability and incapability of three-dimensional imaging, and achieve the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

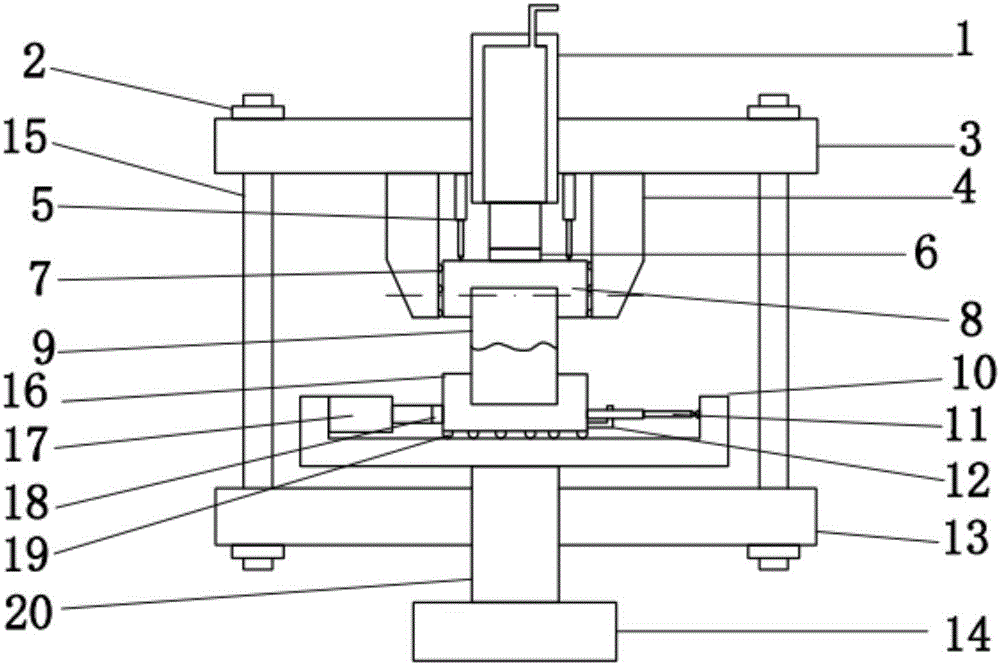

[0025] refer to Figure 1 ~ Figure 4 , a rock joint direct shear test system suitable for CT three-dimensional real-time scanning, including a main frame for carrying a shear instrument, an upper shear box for loading a rock joint test piece, a lower shear box, and a An upper shearing box, a lower shearing box, a rotating device that rotates together with a lateral loading device, and a CT scanning device for realizing three-dimensional CT scanning.

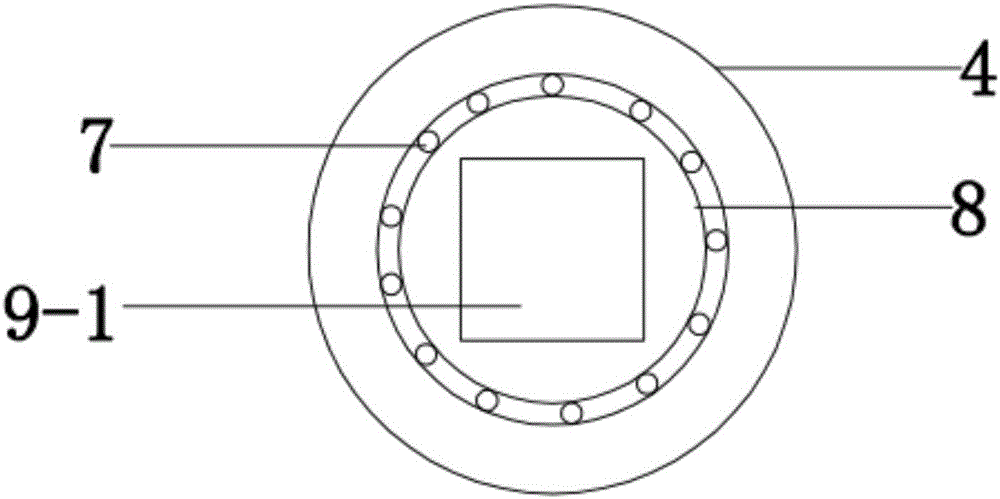

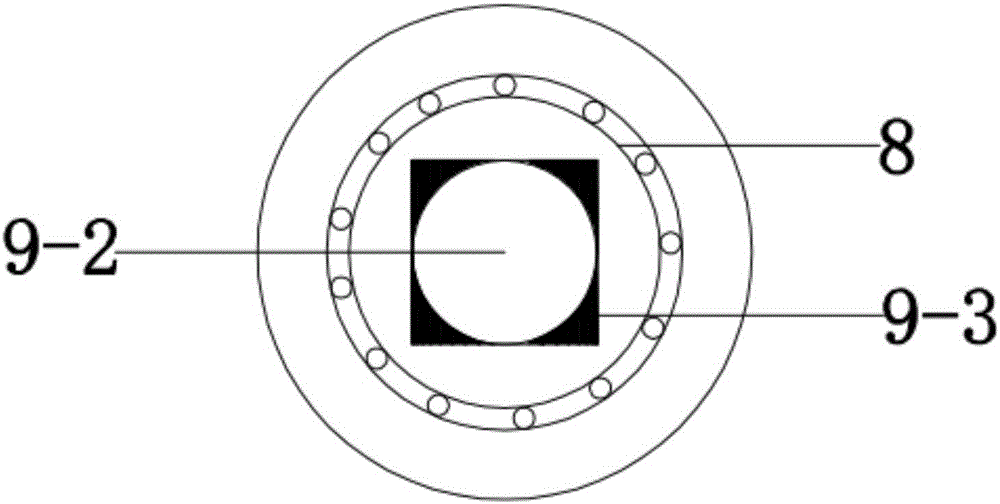

[0026] The rock joint test piece 9 is placed between the upper shear box 8 and the lower shear box 16, and the upper part of the upper shear box 8 is connected to the rotating gasket 6, and the rotating gasket 6 is connected to the normal loading device 1 The action end is connected; the upper shear box 8 is placed in the fixed sleeve 4 used to limit the lateral movement of the upper shear box, and is connected by the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com