Paclitaxel loaded sustained release nano fiber and preparation method and use thereof

A technology of nanofibers and paclitaxel, which is applied in the fields of fiber chemical characteristics, wet spinning method, and pharmaceutical formulations, can solve the problems of side effects, adverse effects of paclitaxel, and reduced drug efficacy, and achieve the effect of reducing toxic and side effects and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) preparation polylactic acid (PLA) concentration is the solution of 0.06 g / ml, solvent used is the mixed solvent of hexafluoroisopropanol, trifluoroethanol or chloroform and acetone;

[0029] (2) preparing paclitaxel concentration is the solution of 10 mg / ml, the solvent used is trifluoroethanol;

[0030] (3) Add a 2.5ml outer syringe to the (1) solution, add a 2.5ml inner syringe to the (2) solution, and adjust the inner and outer layer speeds to 0.2 ml / hour and 0.4 ml / hour respectively, using a No. 9 needle The right-angled flat opening is used as the inner spinneret, the outer spinneret is 10mm, the applied voltage is 15KV, and the fiber is received at a place 10cm directly below the needle tip with a grounded aluminum foil.

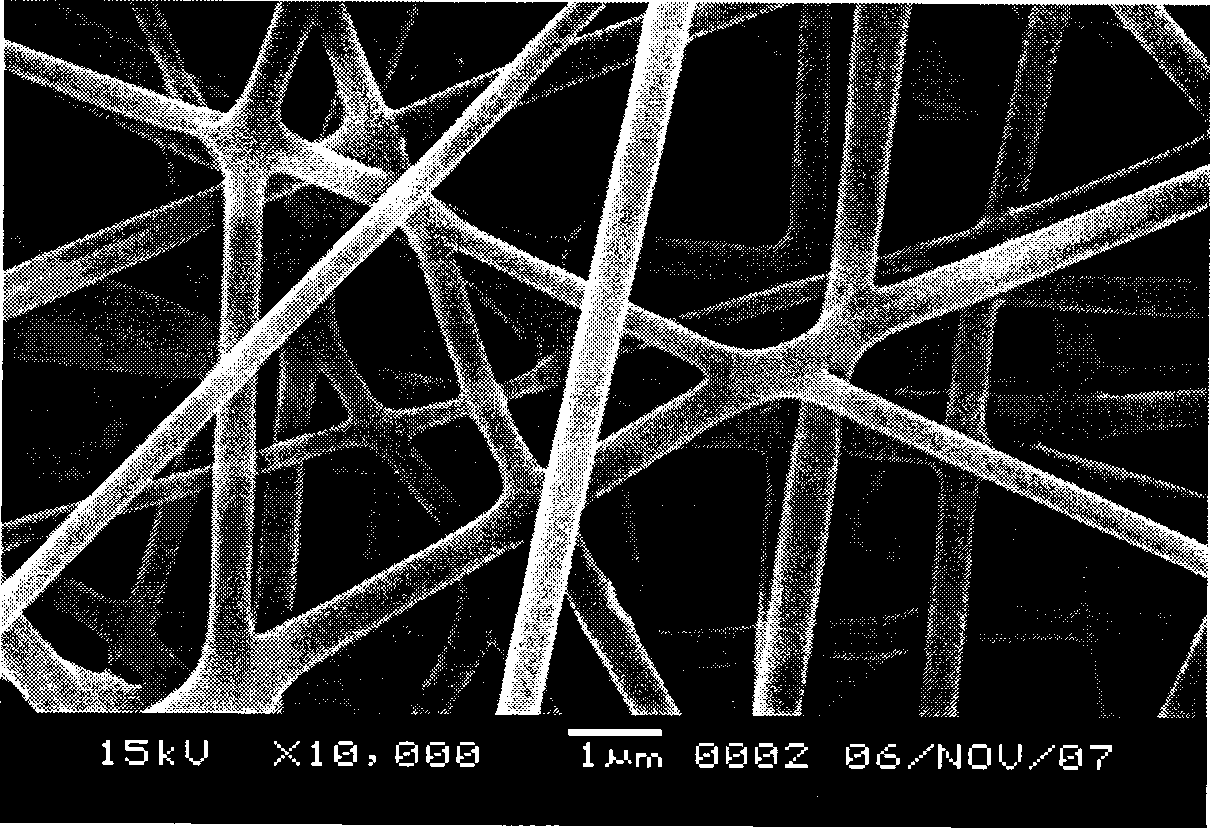

[0031] The average diameter of gained drug-loaded fiber is 175mm, see figure 1 .

Embodiment 2

[0033] (1) preparation polyε-caprolactone (PCL) concentration is the solution of 0.04 g / ml, solvent used is the mixed solvent of hexafluoroisopropanol, trifluoroethanol or chloroform and acetone;

[0034] (2) preparing paclitaxel concentration is the solution of 10 mg / ml, the solvent used is trifluoroethanol;

[0035] (3) Add a 2.5ml outer syringe to the (1) solution, add a 2.5ml inner syringe to the (2) solution, adjust the speed of the inner and outer layers to 0.3ml / hour and 0.5ml / hour respectively, and use a No. 9 needle system The right-angled flat opening is used as the inner spinneret, the outer spinneret is 10mm, the applied voltage is 12KV, and the fiber is received at a place 15cm directly below the needle tip with a grounded aluminum foil.

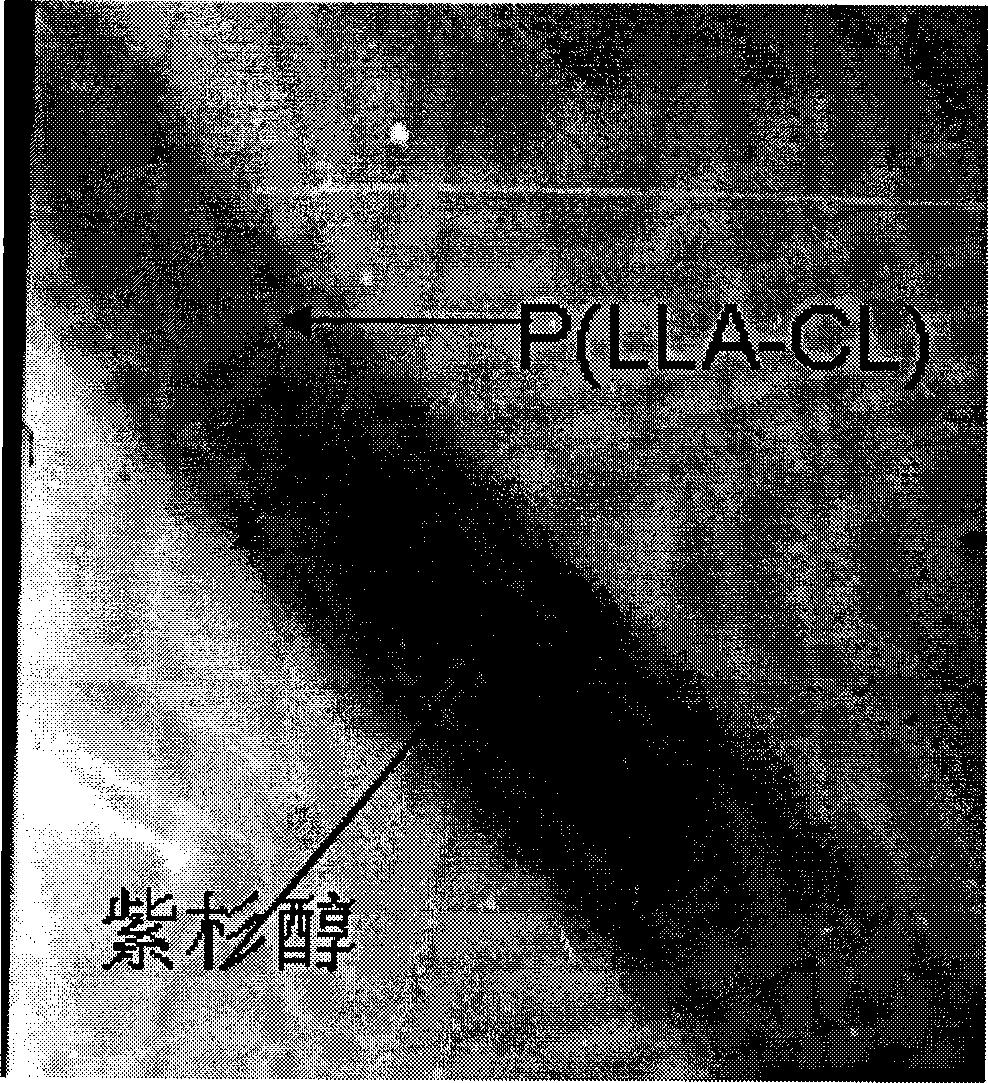

[0036] The average diameter of the obtained drug-loaded fiber is 90nm, and the transmission electron microscope (TEM) test results are shown in figure 2 .

Embodiment 3

[0038] (1) preparation of lactide and caprolactone copolymer [P(LLA-CL)] is a solution of 0.08 g / ml, and the solvent used is a mixed solvent of hexafluoroisopropanol, trifluoroethanol or chloroform and acetone;

[0039] (2) preparing paclitaxel concentration is the solution of 19 mg / ml, the solvent used is trifluoroethanol;

[0040] (3) Add a 2.5ml outer syringe to the (1) solution, add a 2.5ml inner syringe to the (2) solution, and adjust the inner and outer layer speeds to be 0.4 ml / hour and 1.2 ml / hour respectively. The right-angled flat opening is used as the inner spinneret, the outer spinneret is 10mm, the applied voltage is 20KV, and the fiber filament is received at 19cm directly below the needle tip with a grounded aluminum foil.

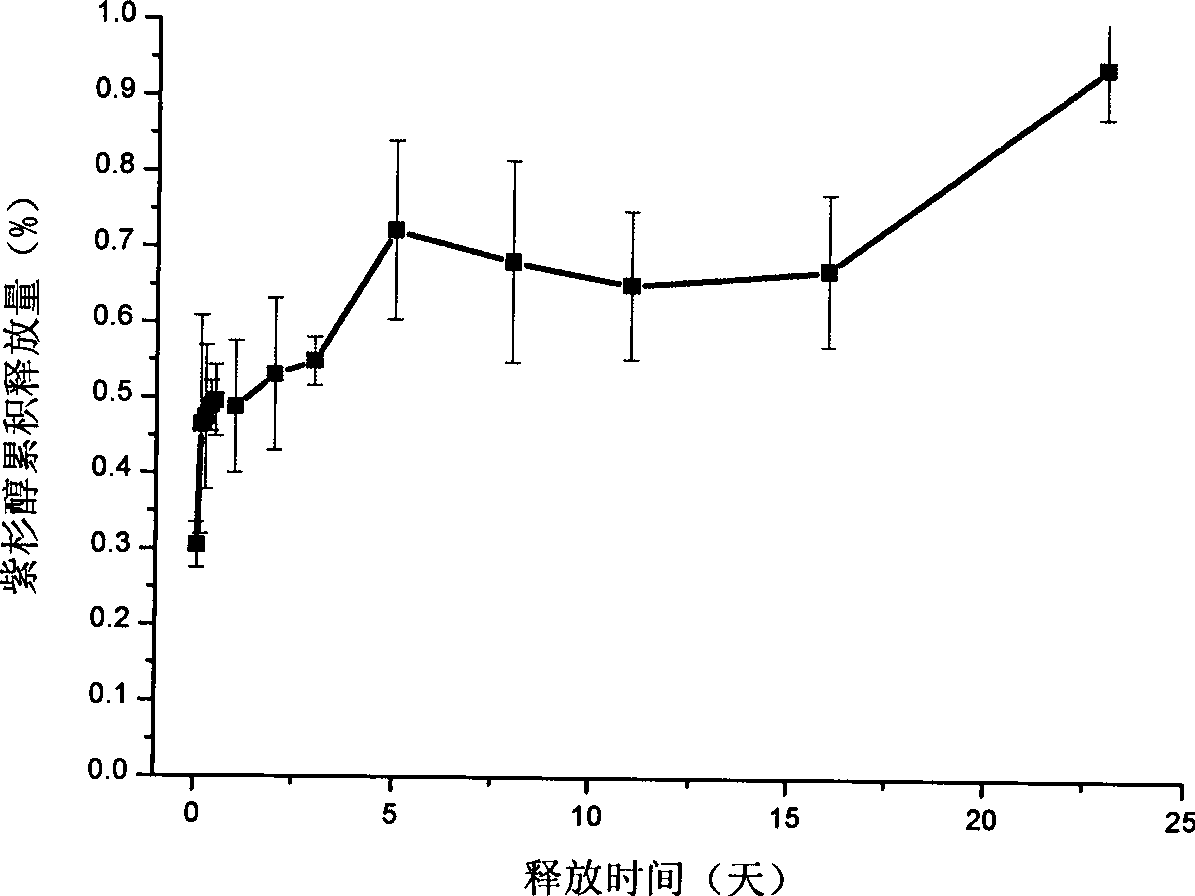

[0041] The average diameter of the obtained drug-loaded fiber is 1.43 μm, the drug-loaded amount of the prepared drug-loaded fiber is 7%, and the encapsulation efficiency is 96.9%. The sustained-release behavior of the prepared drug-loaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com