Coated replacement-resistance type feed additive as well as preparation method and application thereof

A feed additive and coating technology, which is applied in the field of coating-replacement-type feed additive and its preparation, can solve the problems of loss of acidification, poor palatability, large addition amount, etc., and achieves reduced irritation and corrosion, easy control, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

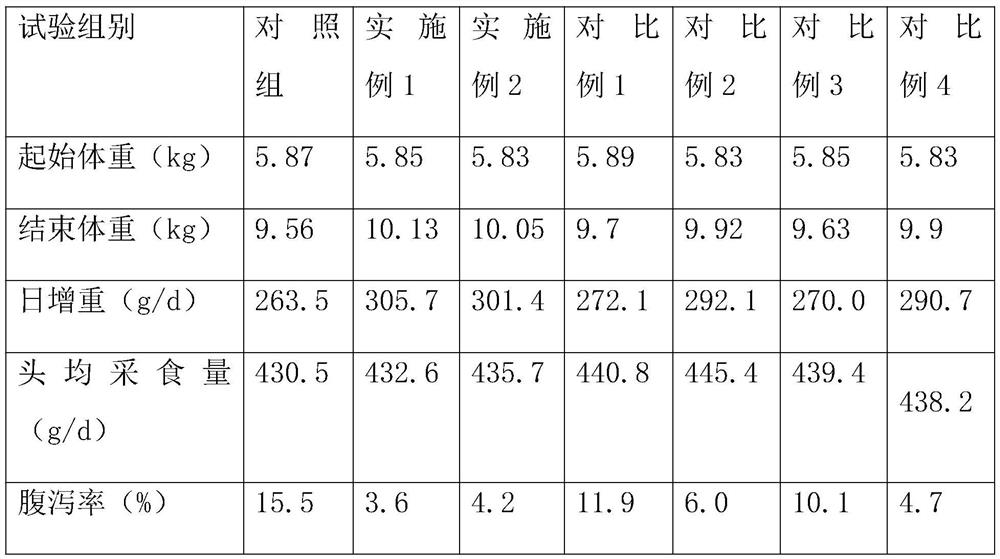

Examples

Embodiment 1

[0026] In the core material of this example, the acidifying agent is a mixture of phosphoric acid, benzoic acid and zinc benzoate in a mass ratio of 1:5:2, the carrier is porous silica with a diameter of 1 μm, and the mass ratio of the acidifying agent to the carrier is 1 : 0.2. The first capsule wall is sodium alginate, the second capsule wall is hypromellose phthalate, and the mass ratio of the core material, the first capsule wall and the second capsule wall is 1:0.02:0.06.

[0027] The preparation method of this embodiment is as follows: load the acidifying agent on the carrier, for example, by simply mixing or drying the solution after mixing, and the carrier will agglomerate during the mixing process to obtain a core material; the natural polymer material Disperse in water to form a wall material dispersion, spray the wall material dispersion on the floating core material, spray for 3 minutes at 25°C, and then float and dry at 60°C to form a primary coating feed additive...

Embodiment 2

[0029] In the core material of this example, the acidifying agent is a mixture of phosphoric acid, benzoic acid and zinc benzoate in a mass ratio of 1:3:1, the carrier is porous silica with a diameter of 5 μm, and the mass ratio of the acidifying agent to the carrier is 1 : 0.2. The first capsule wall is protein, the second capsule wall is polyvinyl alcohol phthalate, and the mass ratio of the core material, the first capsule wall and the second capsule wall is 1:0.05:0.1.

[0030] The preparation method of this embodiment is as follows: load the acidifying agent on the carrier, for example, by simply mixing or drying the solution after mixing on the carrier to obtain a core material; disperse the natural polymer material in water to form a wall material Dispersion, spray the wall material dispersion to the floating core material, spray at 15°C for 5min, then float and dry at 50°C to form a primary coated feed additive; disperse polyvinyl alcohol phthalate in water and Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com