Water-based primer-topcoat coating and preparation method thereof

A bottom surface, water-based technology, applied in the direction of coating, etc., can solve the problems of poor compatibility of coating system, complicated process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

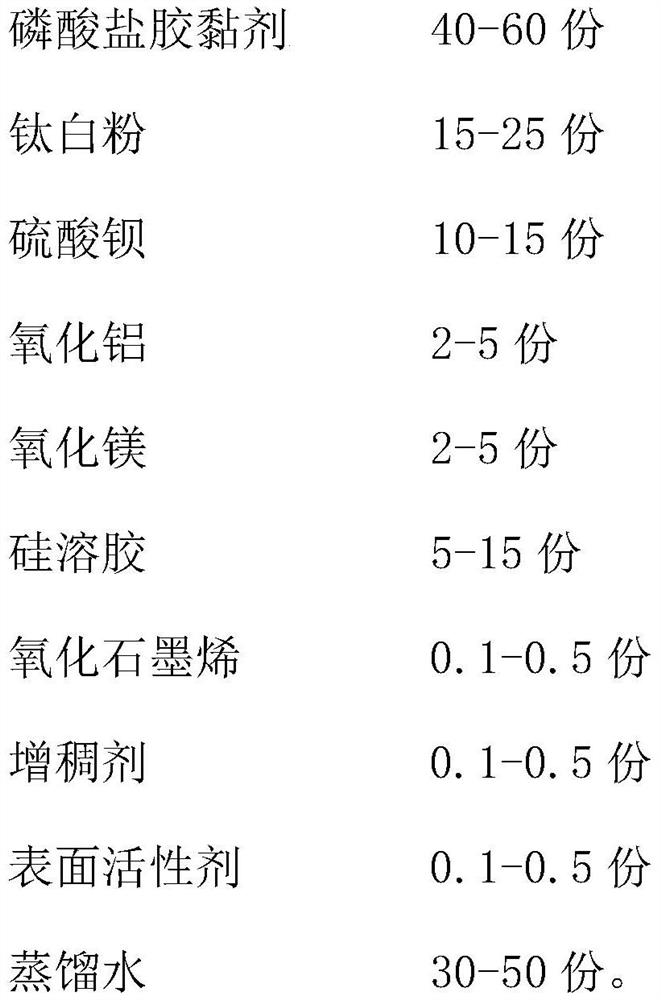

[0039] A water-based bottom surface-in-one coating comprises the following weight components (unit: g):

[0040]

[0041]

[0042] Its preparation method comprises the following steps:

[0043] Step 1, mixing phosphate adhesive, titanium dioxide, barium sulfate, alumina, ultrafine silicon dioxide, silica sol 5g and distilled water 25g to form component A, and ultrasonically dispersing component A;

[0044] In step 2, 3 g of magnesium oxide and 5 g of silica sol are first gelled and mixed by ball milling, and then mixed with other remaining components to form component B;

[0045] Step 3: Add component A and component B into a magnetic stirrer respectively and stir for 30 minutes, the reaction temperature is 50°C, and then ultrasonically disperse to obtain a water-based bottom surface integrated coating.

Embodiment 2

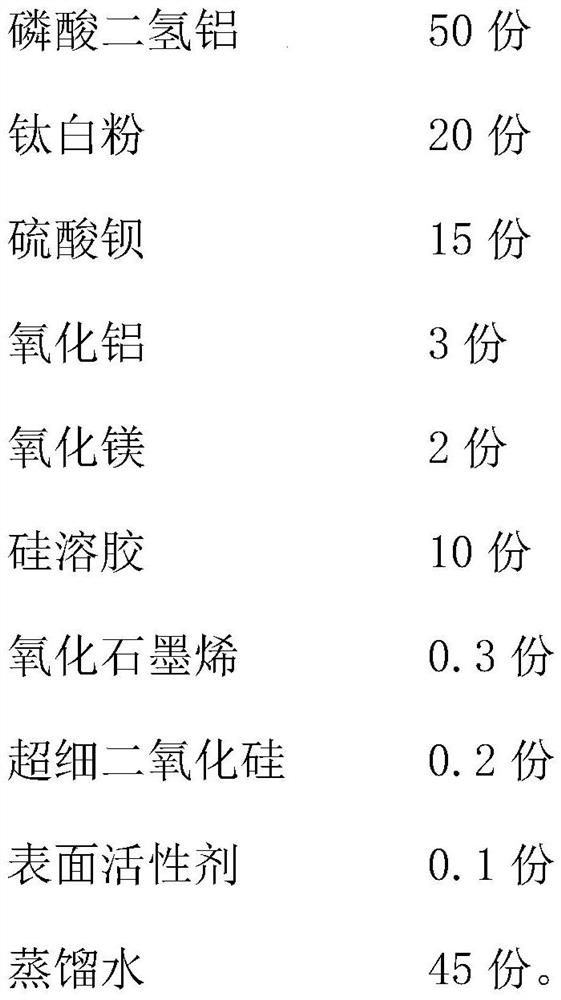

[0047] A water-based bottom surface-in-one coating comprises the following weight components (unit: g):

[0048]

[0049]

[0050] Its preparation method comprises the following steps:

[0051] Step 1, mixing phosphate adhesive, titanium dioxide, barium sulfate, alumina, ultrafine silicon dioxide, silica sol 5g and distilled water 25g to form component A, and ultrasonically dispersing component A;

[0052] In step 2, 5g of magnesium oxide and silica sol are firstly gelatinized and mixed by ball milling, and then mixed with other remaining components to form component B;

[0053] Step 3: Add component A and component B into a magnetic stirrer respectively and stir for 25 minutes, the reaction temperature is 70° C., and then ultrasonically disperse to obtain a water-based bottom surface integrated coating.

Embodiment 3

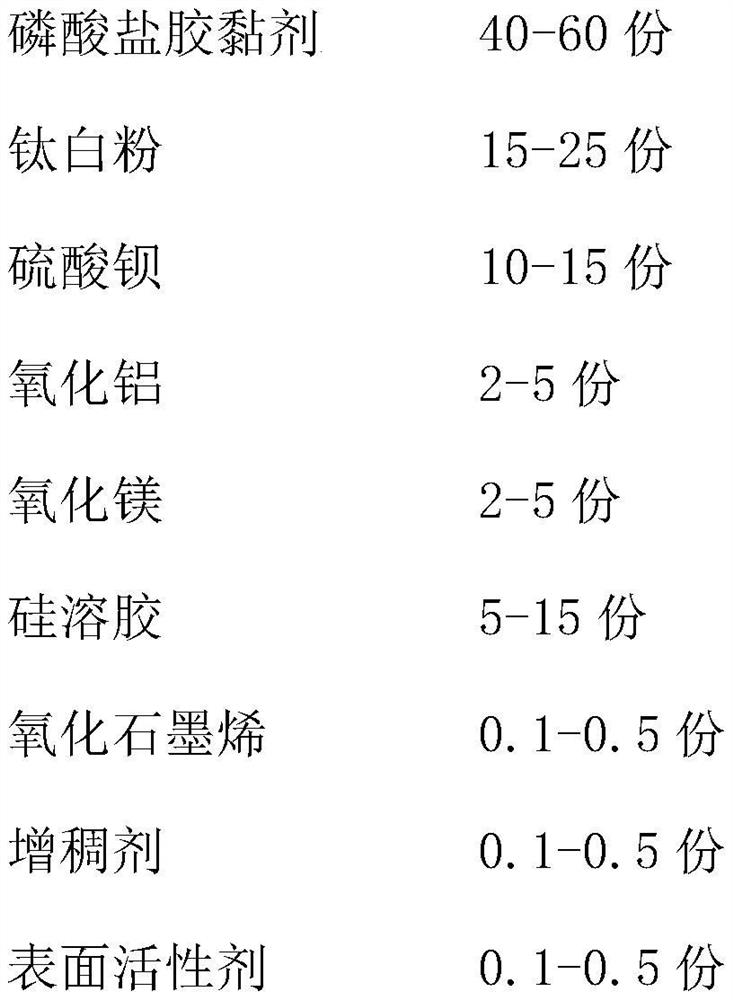

[0055] A water-based bottom surface-in-one coating comprises the following weight components (unit: g):

[0056]

[0057]

[0058] Its preparation method comprises the following steps:

[0059] Step 1. Mix phosphate adhesive, titanium dioxide, barium sulfate, alumina, ultrafine silicon dioxide, silica sol and 25 g of distilled water to form component A, and ultrasonically disperse component A;

[0060] In step 2, 5g of magnesium oxide and silica sol are firstly gelatinized and mixed by ball milling, and then mixed with other remaining components to form component B;

[0061]Step 3: Add component A and component B into a magnetic stirrer respectively and stir for 30 minutes, the reaction temperature is 60° C., and then ultrasonically disperse to obtain a water-based bottom surface integrated coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com