Patents

Literature

34results about How to "Solve refractory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

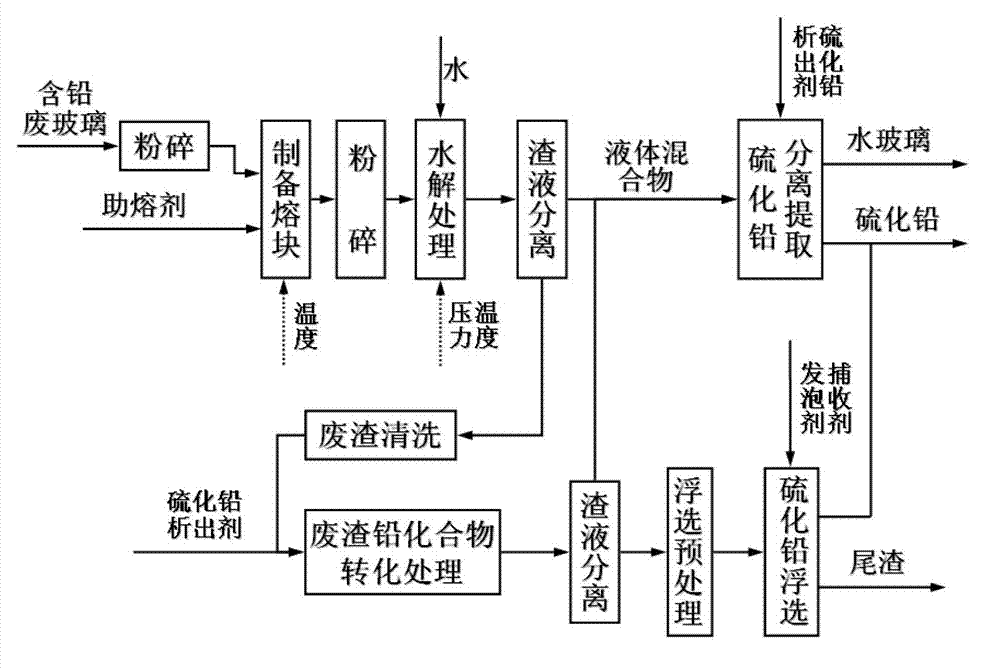

Method for preparing water glass by utilizing waste lead-containing glass and separating lead-containing compound

ActiveCN102826562ASolve refractoryLower melting temperatureAlkali metal silicatesLead sulfidesLead smeltingInorganic Chemical

The invention relates to a method for preparing water glass by utilizing waste lead-containing glass and separating a lead-containing compound. The method comprises the following steps of: firstly, making the lead-containing glass of an abandoned cathode-ray tube (CRT) into water glass fusion cake, hydrolyzing the fusion cake, and separating hydrolysate to obtain a water glass solution; then adding an additive to convert lead dissolved in the water glass into lead sulphide, separating and collecting lead sulphide sediment to obtain a lead-free potassium or sodium water glass solution, further treating dissolved residue to convert the lead-containing compound in the residue into lead sulphide, and recycling lead sulphide in the hydrolysis residue by adopting a floatation method. The method disclosed by the invention has the advantages that silicon, potassium and sodium ingredients in the lead-containing glass of the abandoned CRT can be converted into the water glass, recycling of the lead-containing compound is solved; the water glass is a basic inorganic chemical industry product with wide application range; and recycling of the lead-containing compound is solved, the recycled lead-containing compound can be taken as a raw material for lead smelting, and recycling of lead resource is realized.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Smelting method of chromium-molybdenum-copper-nickel-tin-antimony low-alloy wear-resistant cast iron

InactiveCN104178684AGuaranteed elemental compositionGuaranteed Concurrent Eligibility RequirementsWear resistantManganese

The invention discloses a smelting method of a chromium-molybdenum-copper-nickel-tin-antimony low-alloy wear-resistant cast iron, which comprises the following steps: raw material weighing: preparing and weighing raw materials and alloys according to the prescribed material specifications and weight proportion; smelting: sequentially adding the materials according to the technical charging sequence, and melting, wherein refractory molybdenum iron, chromium iron and pure nickel are added in the middle of the pig iron batch charging process, and scrap steel is added; component adjustment: adding silicon iron and manganese iron to adjust to acceptable components, heating, and adding a copper block which can be easily damaged by fire; and late inoculation in casting ladle: before tapping and after preheating the casting ladle, adding a tin block (accounting for 0.05% of the raw materials) and an antimony block (accounting for 0.01% of the raw materials) to the bottom of the ladle, and adding late inoculation silicon granules into the molten iron in the ladle in the casting process. The method solves the problem that the high-melting alloy added after all the iron liquid is completely molten is refractory, is capable of shortening the melting time and enhancing the smelting efficiency, promotes the formation of the fine lamellar pearlite, and ensures the element components, mechanical properties and metallurgical structure of the casting to simultaneously satisfy the requirements.

Owner:HEBEI FENGWEI MACHINERY

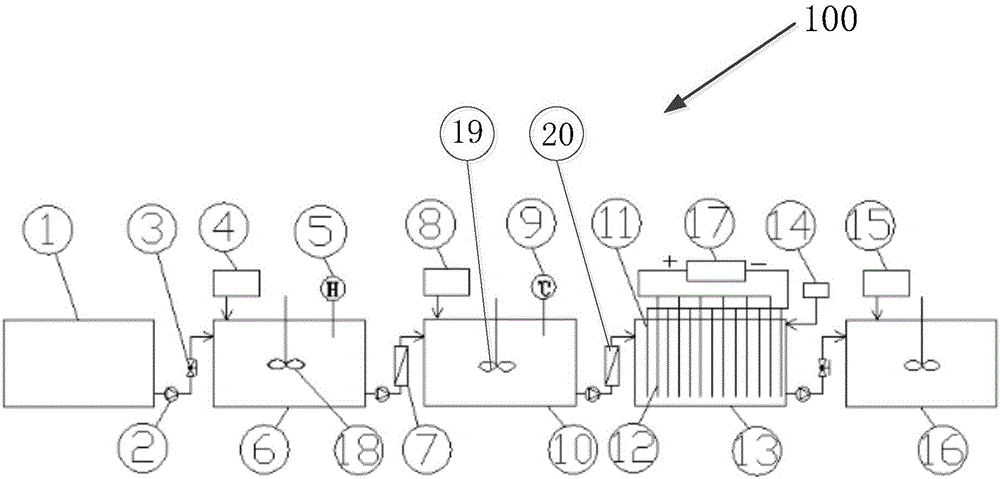

Brown waste liquid treatment device and brown waste liquid treatment method

InactiveCN106115991AHigh purityAvoid complexationTreatment involving filtrationMultistage water/sewage treatmentLiquid wasteElectrolysis

The invention is applicable to the field of waste water treatment, and provides a brown waste liquid treatment device. The brown waste liquid treatment device comprises a storage device for storing brown waste liquid, an electrolyzer used for electrolytic treatment of the brown waste liquid, and a COD (chemical oxygen demand) degradation device for oxidizing the brown waste liquid. The COD degradation device is connected between the storage device and the electrolyzer. The invention further provides a brown waste liquid treatment method. The brown waste liquid treatment device has the advantages that the COD degradation device is used for oxidizing the brown waste liquid before electrolytic treatment, and copper type slow-release agents such as 1H-benzotriazole in the brown waste liquid can be oxidized, so that bright blocky high-quality copper with high purity can be obtained.

Owner:SHENZHEN JECH TECH

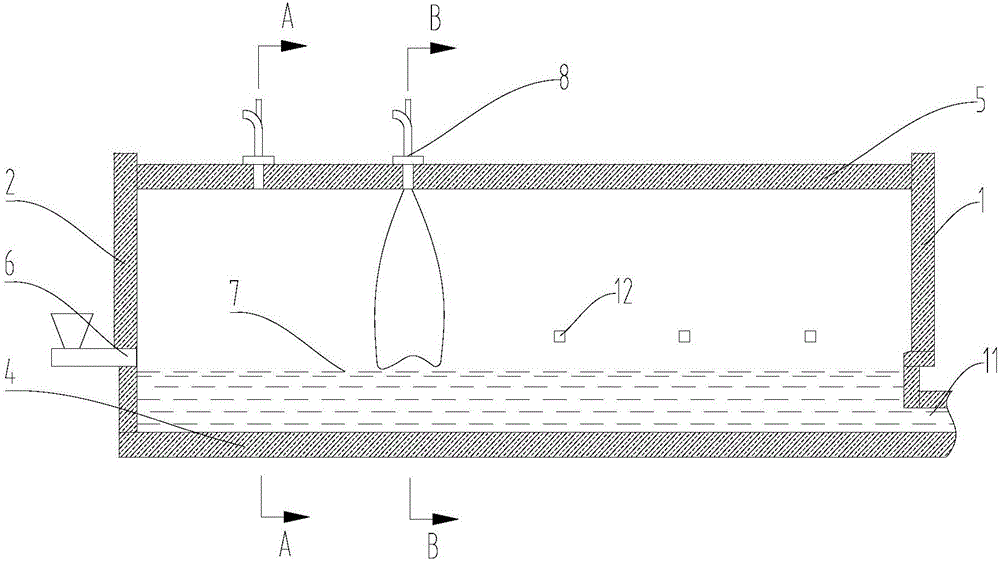

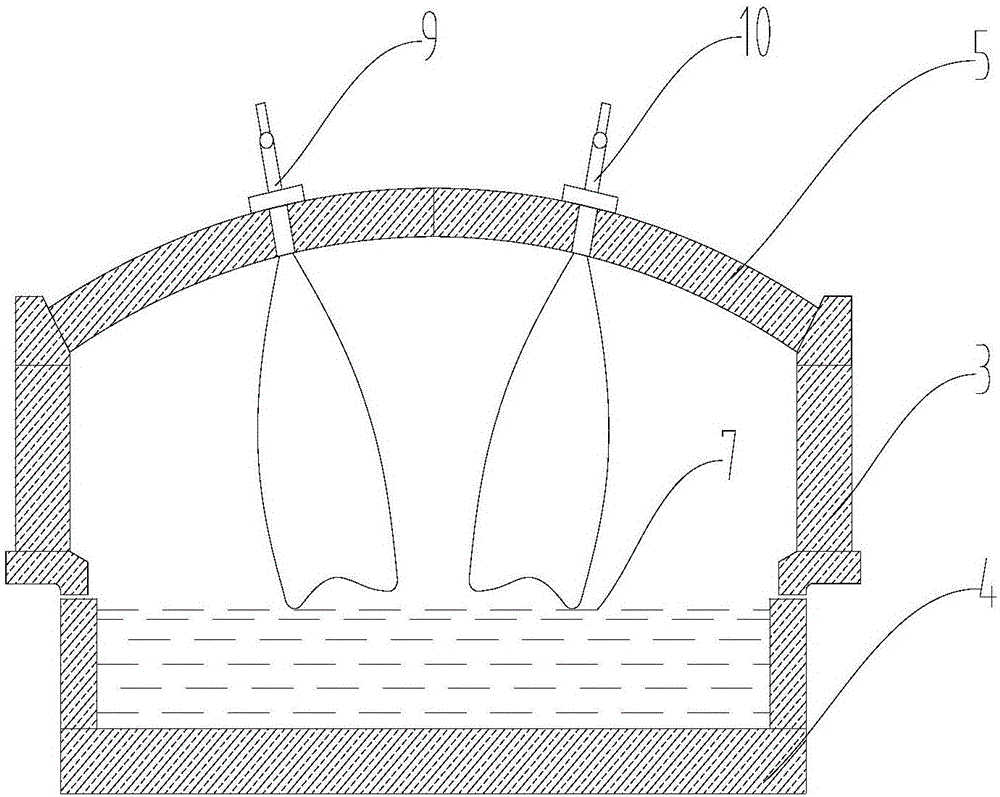

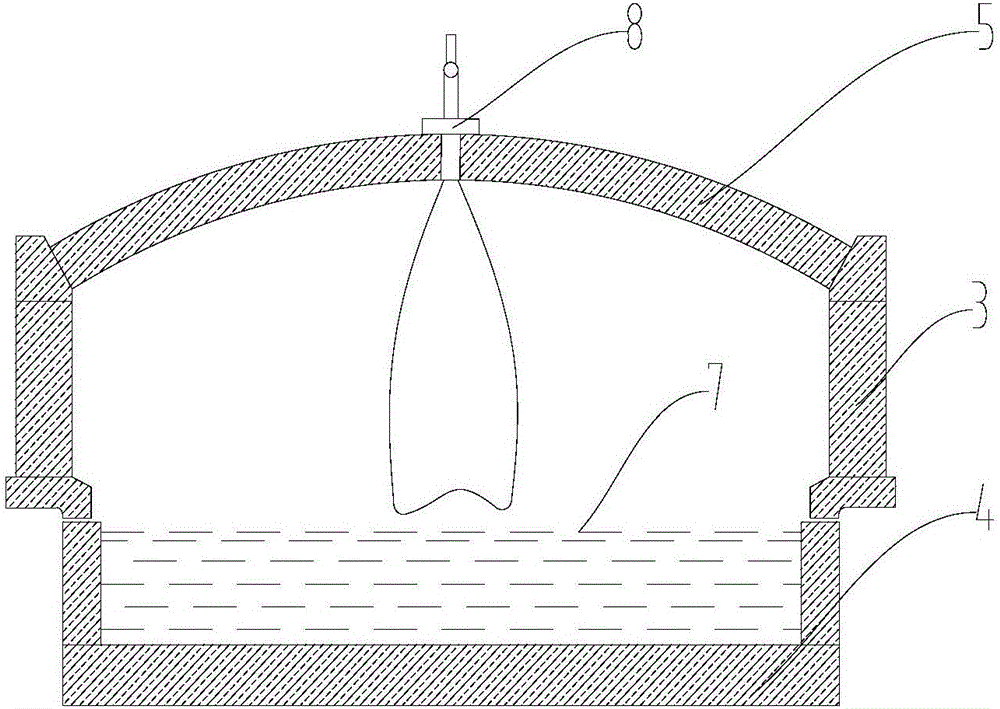

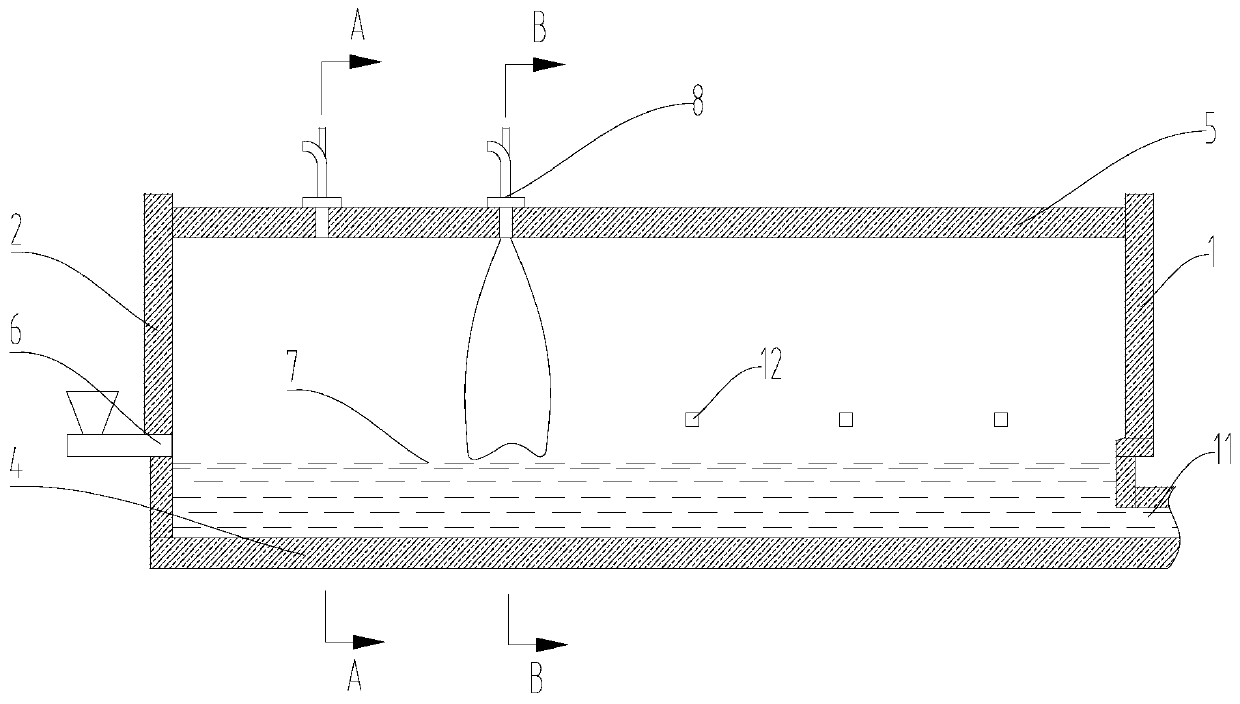

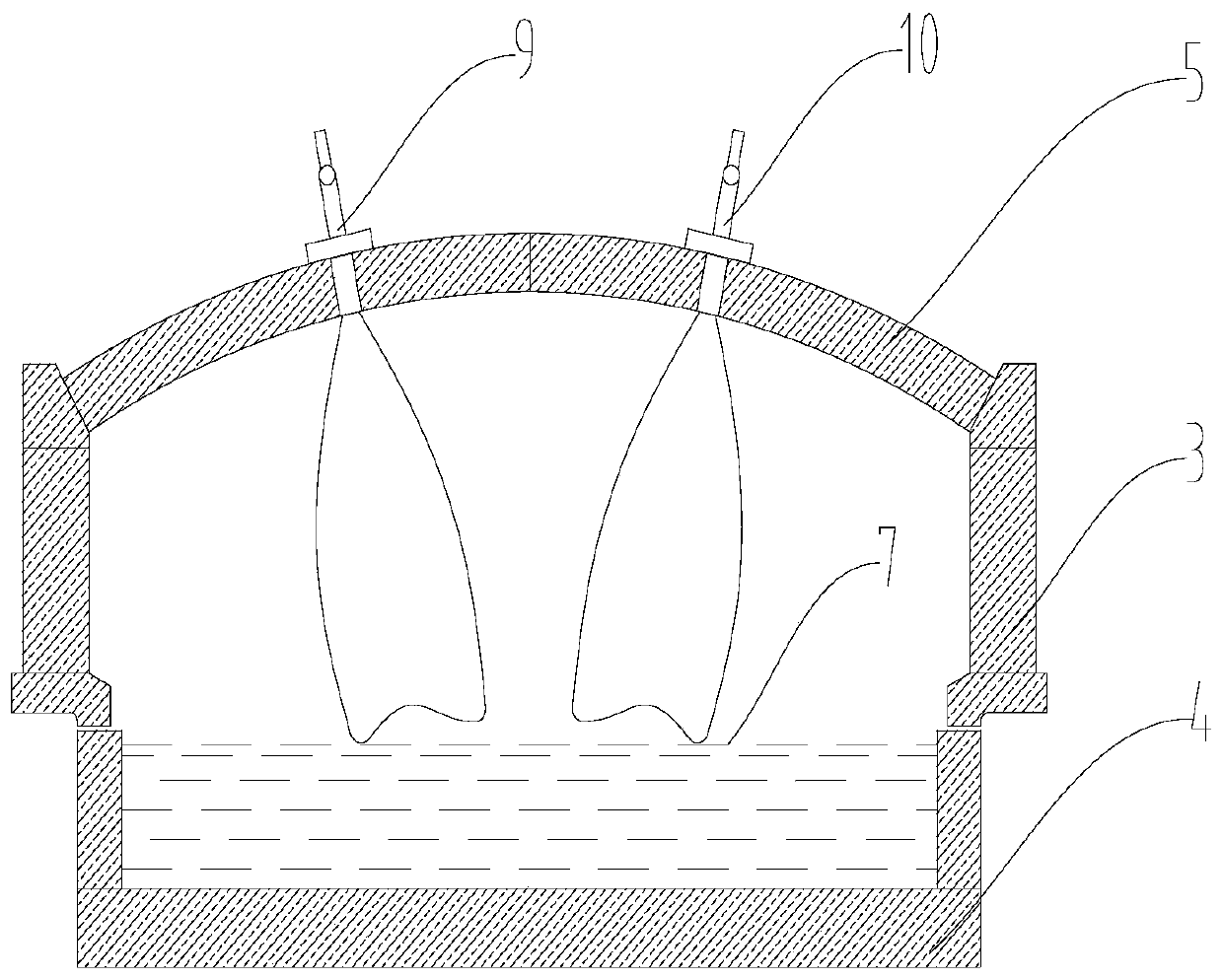

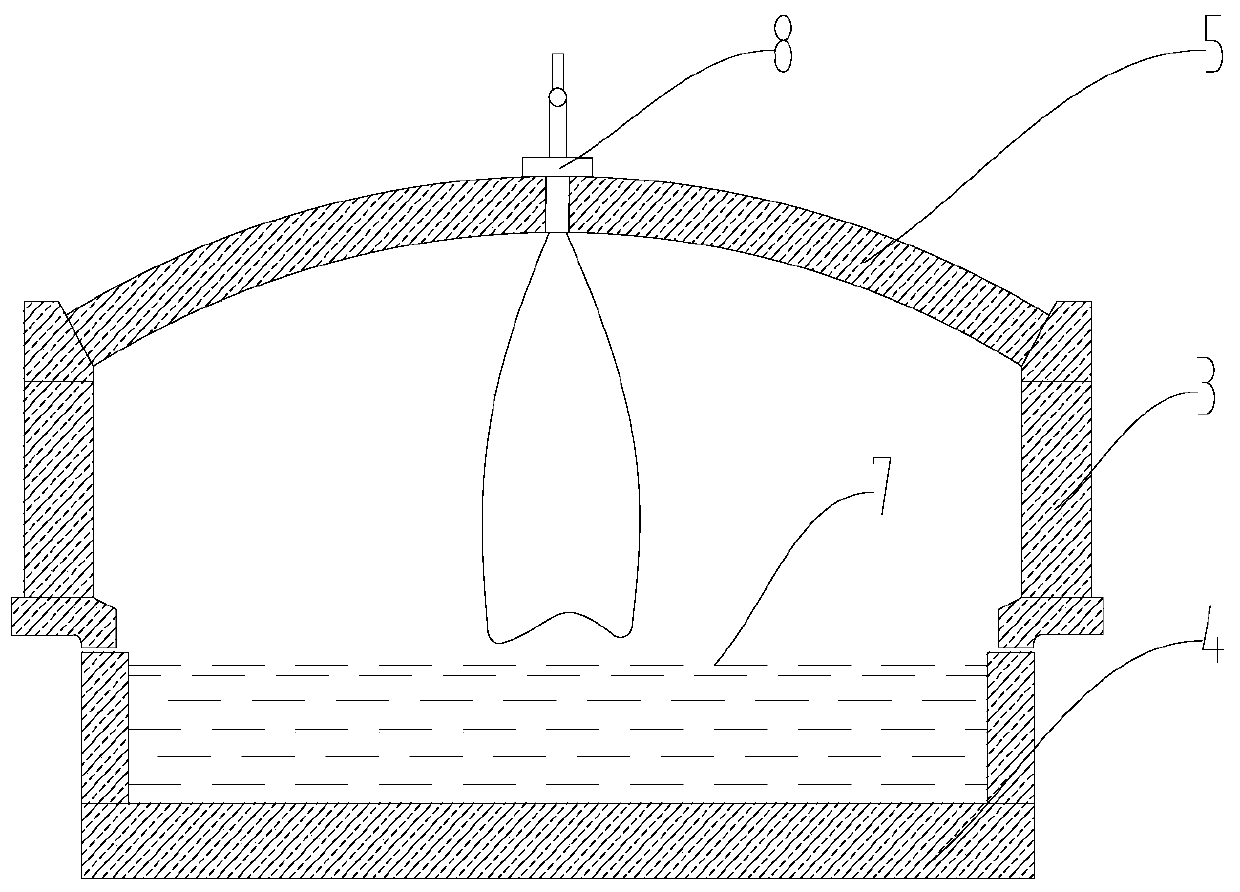

Glass kiln

ActiveCN106746501ASpeed up heat transferIncrease heat radiationGlass furnace apparatusMelting tankCombustion

The invention relates to a glass kiln. The glass kiln comprises a melting tank and an arch (5), wherein the melting tank is defined by a front end wall (1), a rear end wall (2), a side wall (3) and a bottom wall (4), and the arch (5) is located at the top of the melting tank; and a feeding hole (6) is formed in the rear end wall (2), and a first combustion device capable of ejecting flame to a glass liquid level (7) is arranged at one end, close to the feeding hole (6), of the arch (5). The first combustion device is arranged at the region close to a glass liquid inlet hole and is capable of directly ejecting the flame to the glass liquid level, the glass liquid is directly heated through the convection current generated by the thermal radiation and hot flue gas of the flame, the heat transfer and thermal radiation of a glass batch can be reinforced, and the heat transfer caused by the heat to the glass liquid is maximized, so that the problem that partial part of powder is difficulty melted is solved. Besides, the glass liquid is directly subjected to the thermal radiation and the heat transfer by the vertical combustion flame on the arch, so that the burning of the side wall can be avoided.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Recyclable coating material and preparation method thereof

The invention relates to a coating material and a preparation method thereof, particularly a recyclable coating material and a preparation method thereof. The coating material is composed of the following components in parts by weight: 100 parts of corn starch, 8-16 parts of carboxyethyl cellulose, 3-8 parts of alkyd resin, 12-20 parts of low density polyethylene resin, 3-8 parts of glycerol, 4-10 parts of calcium stearate, 1-5 parts of liquid paraffin, 1.0-1.6 parts of calcium propionate, 1.2-1.8 parts of titanium white, 0.5-0.8 part of reinforced modifier, 0.1-0.5 part of stabilizer and 0.2-0.6 part of initiator. The coating material solves the problem of low degradability of the coating material in the prior art, implements recycling, protects the environment and saves the resources.

Owner:ANHUI ZHONGCAI PRINTING

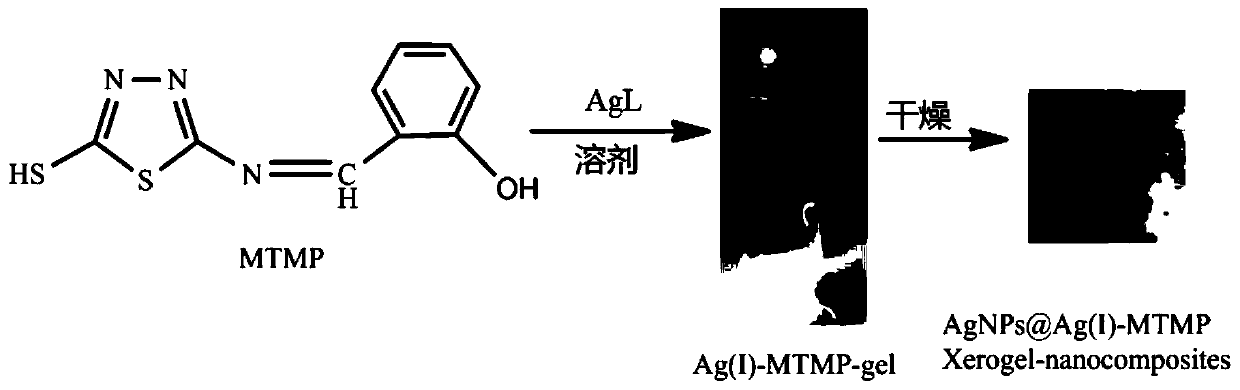

Double-function mercapto Schiff base metal organogel-nanometer composite material, and preparation method and applications thereof

The invention discloses a double-function mercapto Schiff base metal organogel-nanometer composite material, and a preparation method and applications thereof. The double-function mercapto Schiff basemetal organogel-nanometer composite material AgNPs@Ag(I)-MTMP contains silver nanometer particle AgNPs, Ag(I)-MTMP, and a solvent; AgNPs is adsorbed by Ag(I)-MTMP, and the solvent is coated by Ag(I)-MTMP through hydrogen bonds and molecular effect; the chemical structure of Ag(I)-MTMP is [Ag(MTMP)]n(L)n, [Ag(MTMP)]n<n+> structure is represented by formula I, wherein L is used for representing a minus monovalence negative ion, n is used for representing a positive integer, MTMP is 2-((5-mercapto-1, 3, 4-thiadiazole-2-imino)methyl)phenol. The double composite material is capable of removing acidic organic dye molecular through high efficiency adsorption, and possesses antibacterial function.

Owner:ANHUI NORMAL UNIV

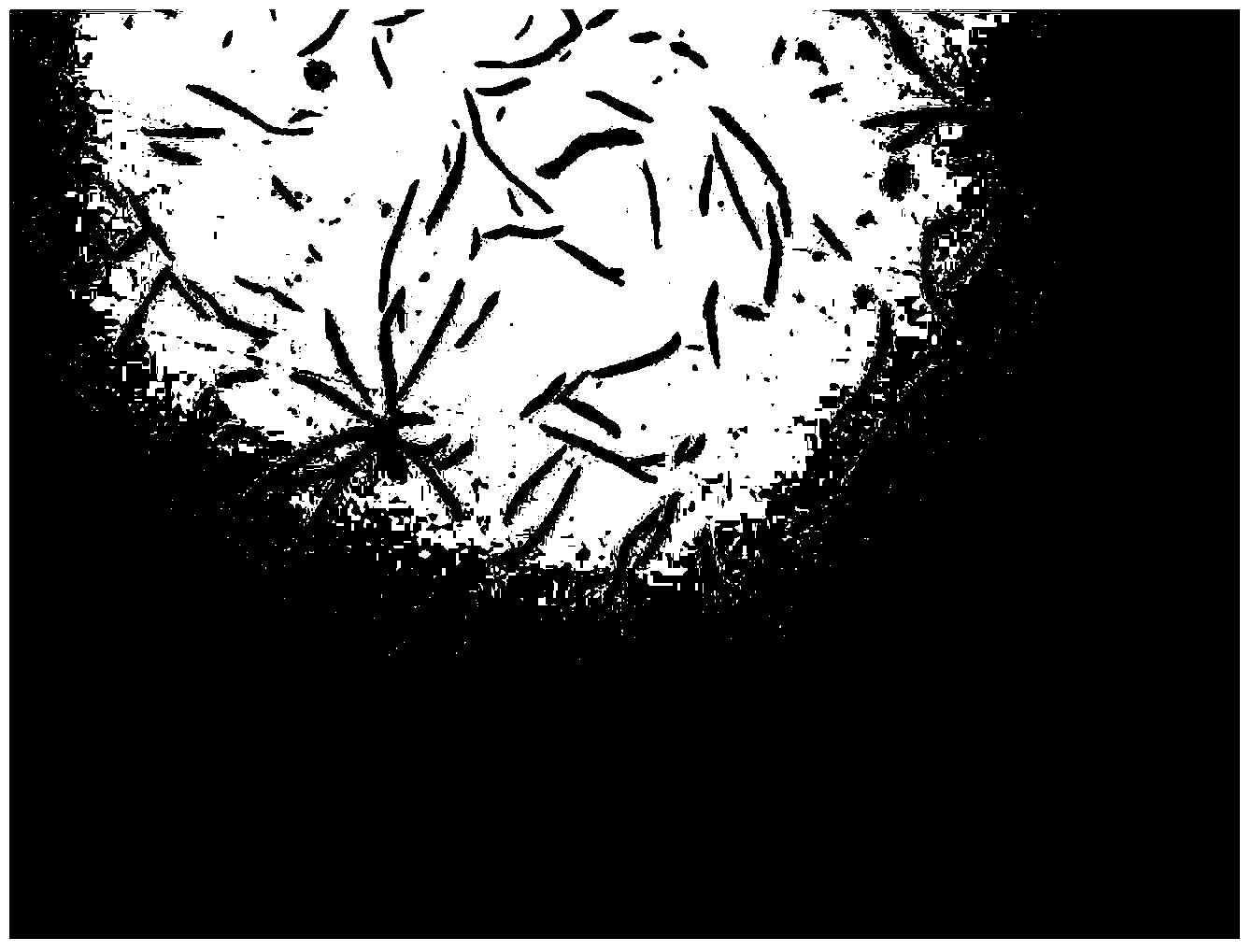

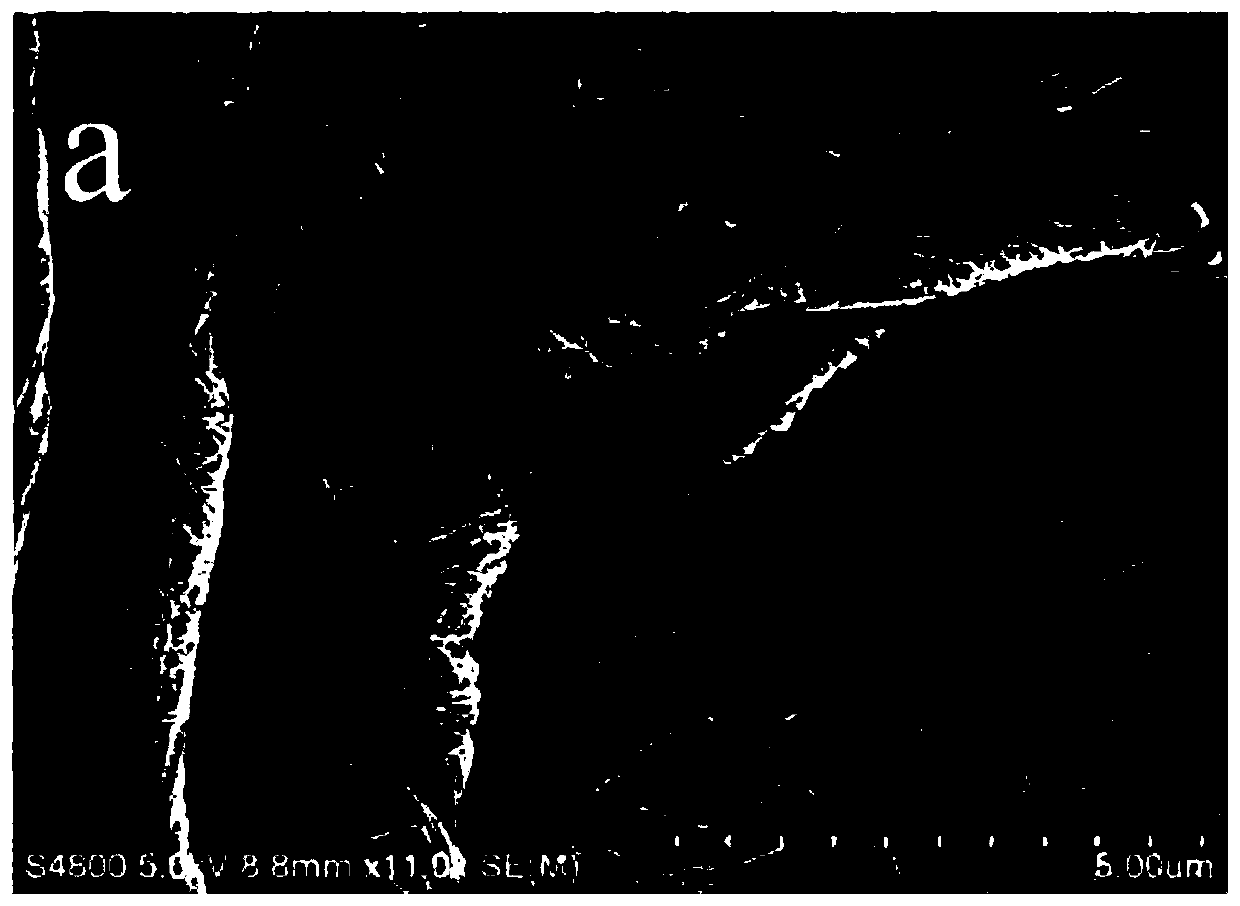

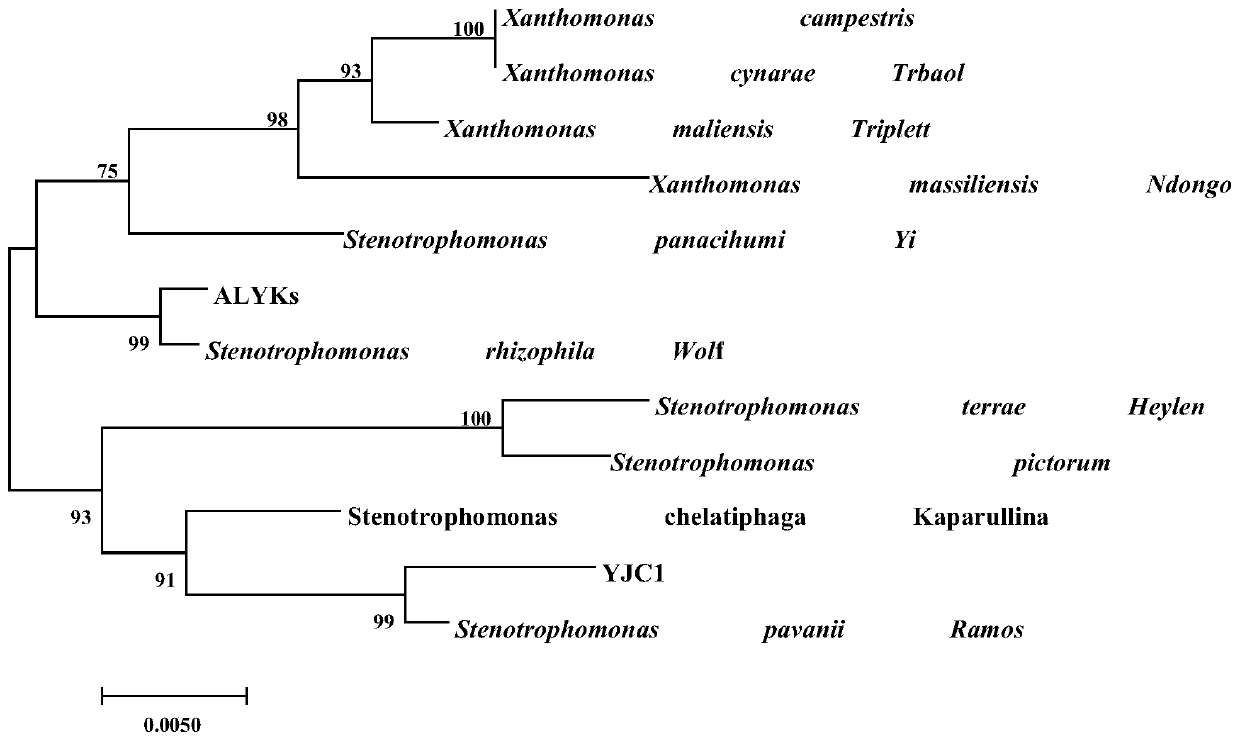

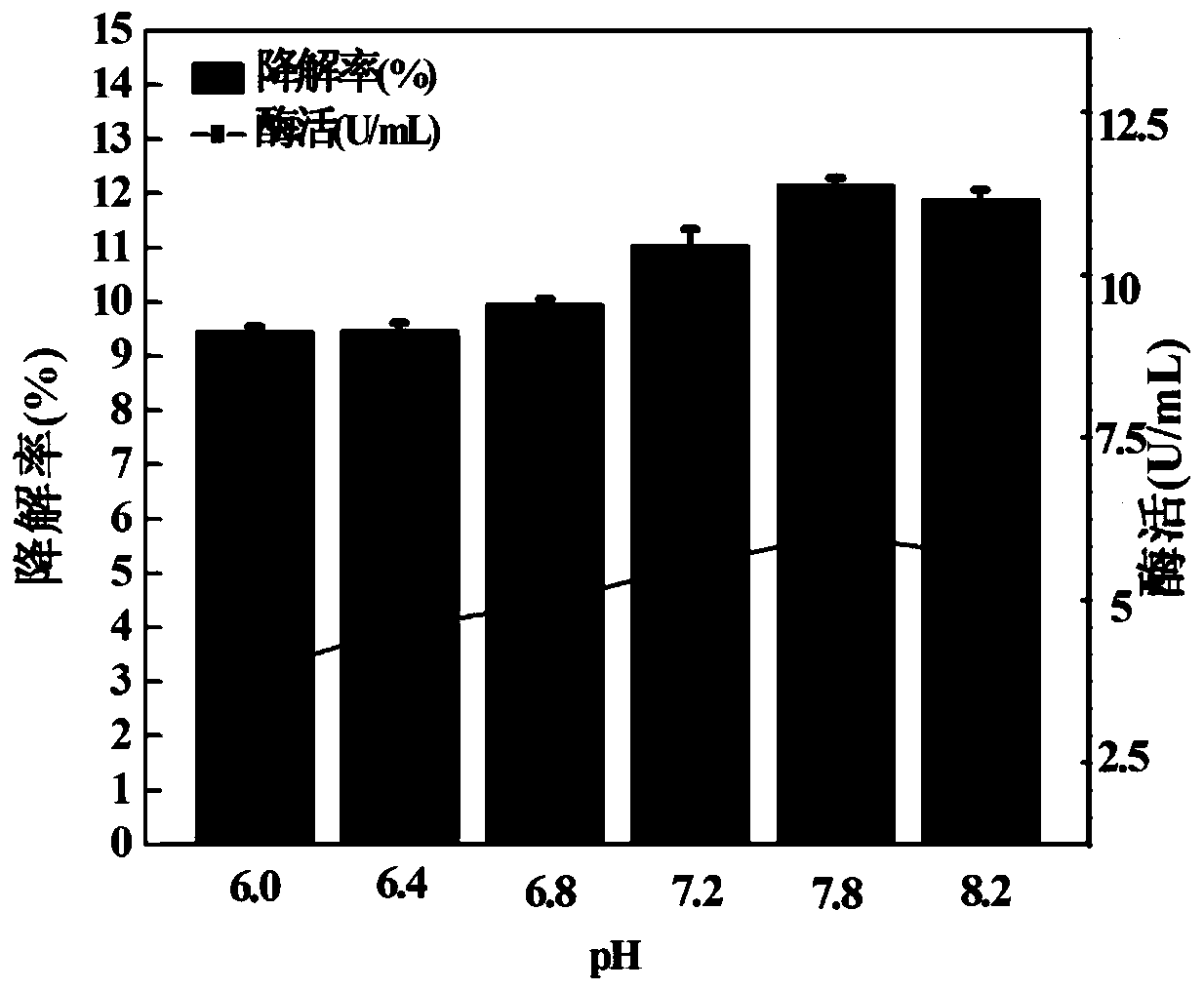

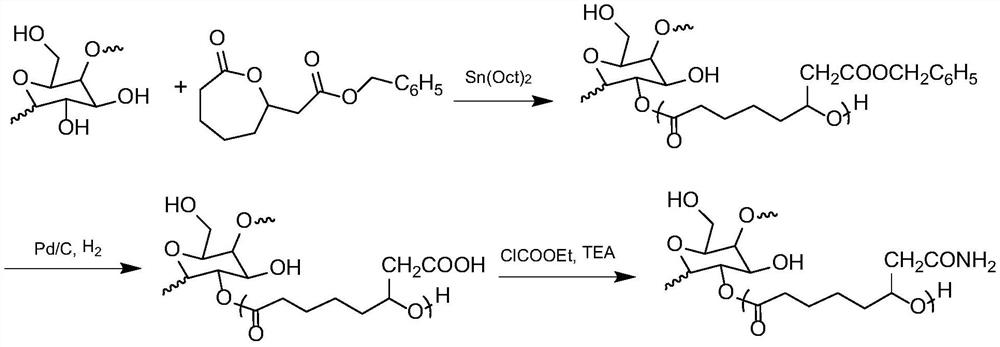

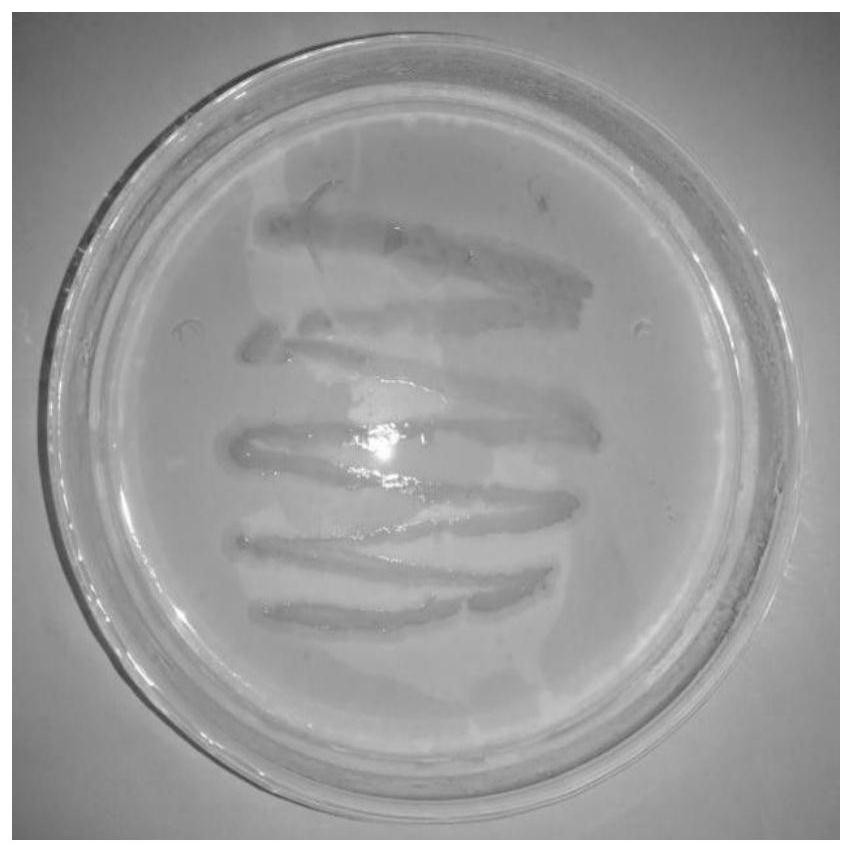

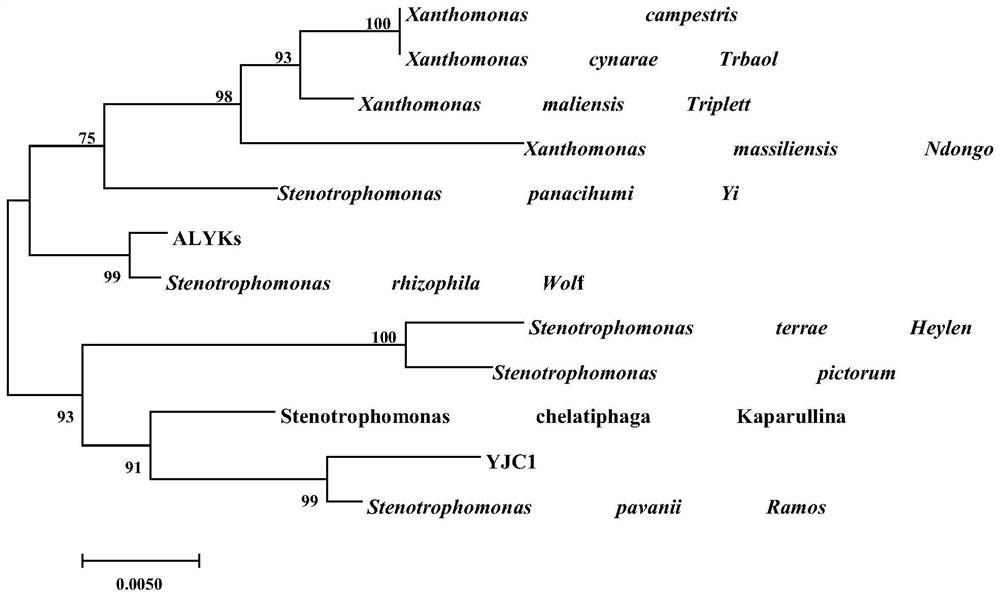

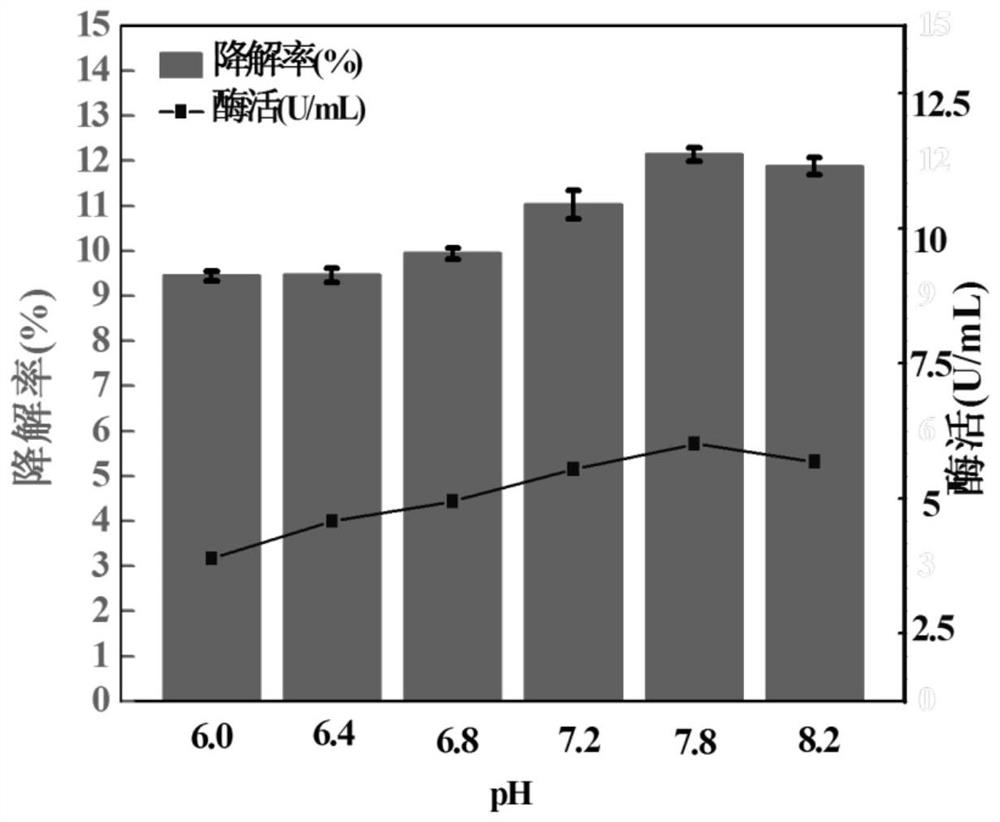

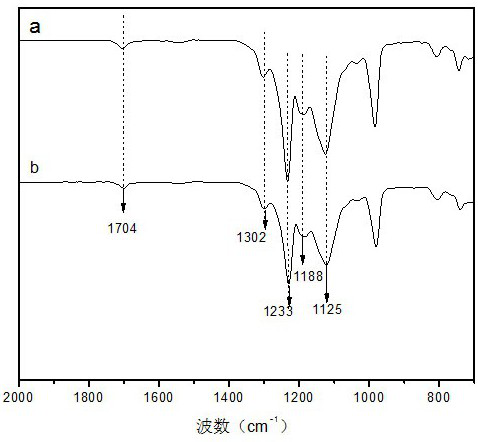

Stenotrophomonas for efficiently degrading poly(butylene adipate-co-terephthalate) and application thereof

The invention provides stenotrophomonas for efficiently degrading poly(butylene adipate-co-terephthalate) and application thereof. A strain of poly(butylene adipate-co-terephthalate) (PBAT) degradingbacteria capable of secreting lipase is separated and screened out of the soil in Yanxia town, Liquan county, Shanxi province, and the stenotrophomonas is named as Stenotrophomonas sp.strain YCJ1, ispreserved in China Center For Type Culture Collection and has the preservation number of CGMCC 18059. The stenotrophomonas has the advantages that the stenotrophomonas can secret lipase and efficiently degrade PBAT, the stenotrophomonas has a more excellent degrading effect under the slightly alkaline conditions, and the stenotrophomonas and the lipase thereof can be applied as enzymic preparations, biological bactericides and biological enhancers to the environment repairing of PBAT and PBAT-base biodegradable materials in the slightly alkaline environment and have high application value.

Owner:SHAANXI UNIV OF SCI & TECH

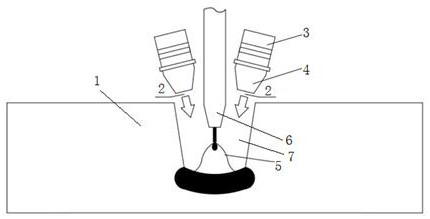

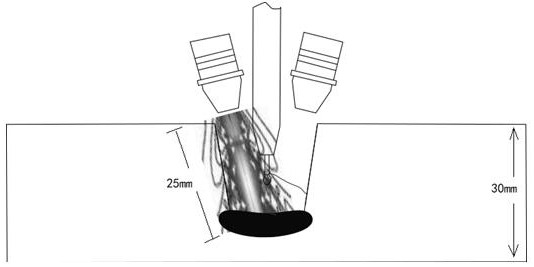

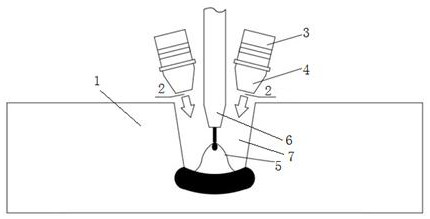

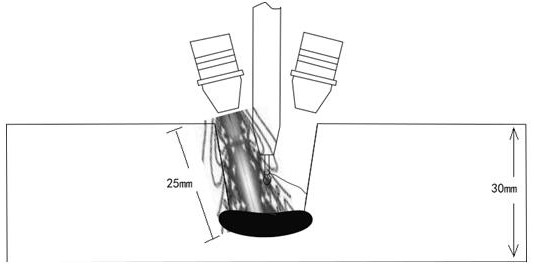

Alternating ultrasonic field assisted narrow gap welding method

ActiveCN113070595AIncrease energy densityStrong penetrating powerWelding apparatusEngineeringArc energy

The invention discloses an alternating ultrasonic field assisted narrow gap welding method. The alternating ultrasonic field assisted narrow gap welding method comprises the following steps of 1) placing a machined welded workpiece on a welding platform, beveling the welded workpiece, pressing four corners, correspondingly placing an ultrasonic device on each of the two sides above a groove, correspondingly pointing the lower ends of ultrasonic generators to the other opposite side of the groove, and arranging an electrode between the two ultrasonic devices; 2) welding, specifically, enabling the left and right ultrasonic devices to alternately work to promote the electric arc to swing left and right; (3) in a welding process, adjusting power and frequency parameters of the ultrasonic devices, changing arc deflection amplitude, and enabling arc parameters to reasonably match with the ultrasonic parameters; and (4) after completing welding, closing the system, air-cooling to room temperature, wiping cleanly, and completing welding. According to the alternating ultrasonic field assisted narrow gap welding method, it is guaranteed that an ultrasonic field can effectively control arc deflection, the arc is compressed, arc energy is enhanced, and the key problem that the side wall of the narrow gap is difficult to melt is effectively solved.

Owner:YANTAI UNIV

glass furnace

ActiveCN106746501BSpeed up heat transferIncrease heat radiationGlass furnace apparatusGlass furnaceDirect heating

The disclosure relates to a glass furnace, comprising a melting pool surrounded by a front end wall (1), a rear end wall (2), a side wall (3) and a bottom wall (4), and a slab located above the melting pool The top (5), the rear end wall (2) is provided with a material inlet (6), and one end of the roof (5) close to the material inlet (6) is provided with a device capable of facing the glass liquid surface ( 7) First combustion means for injecting flame. The first combustion device is installed in the area close to the glass liquid inlet, which directly sprays flames towards the glass liquid surface. The heat radiation of the flame and the hot smoke convection directly heat the glass liquid, which can strengthen the heat transfer and heat transfer of the glass batch materials. Radiation maximizes the heat transfer of heat to the molten glass, thereby solving the problem of some powder refractory. In addition, the burning flame of the dome directly radiates and transfers heat to the molten glass, and the flame is vertical, which can avoid burning the side wall.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

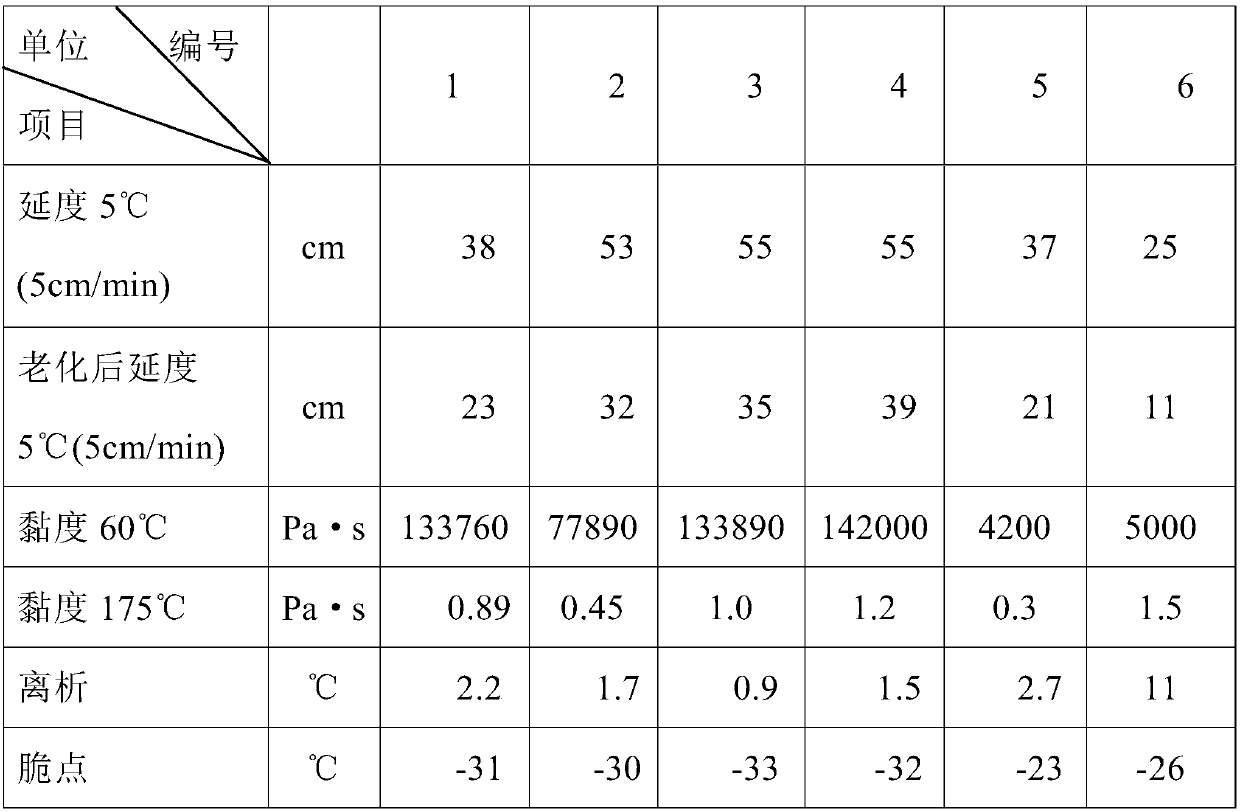

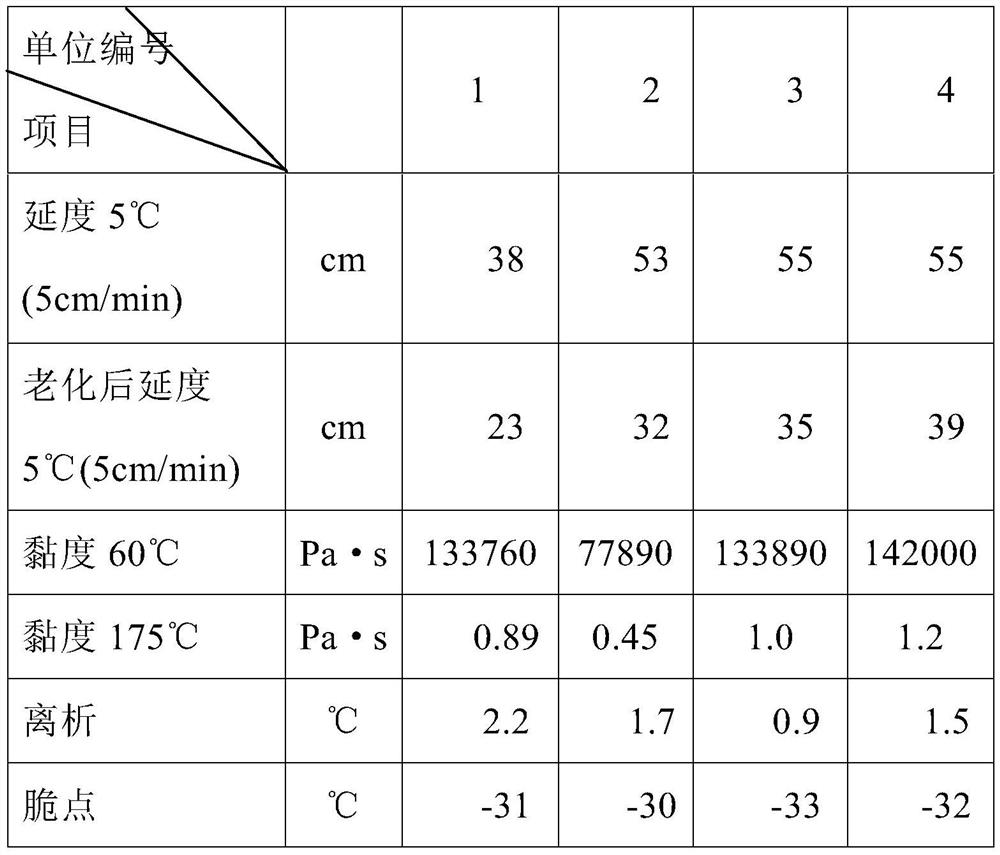

High-rubber asphalt master batch and low-temperature environmental-friendly production process thereof

ActiveCN109810521ARealize environmentally friendly useShorten the production cyclePlastic recyclingBuilding insulationsPolymer scienceChain type

The invention relates to a high-rubber asphalt master batch and a low-temperature environmental-friendly production process thereof. A raw material is prepared from the following ingredients in percentage by weight: 10 to 50 parts of vulcanized rubber powder, 5 to 15 parts of deconstruction agents and 40 to 80 parts of substrate asphalt. The high-rubber asphalt master batch is prepared by the following steps of firstly performing desulfurization degradation on vulcanized rubber powder; then, adding the substrate asphalt; performing blending to obtain a homogeneous blended material. By using the high-rubber asphalt master batch provided by the invention, the problems of great smell, substandard discharge and the like in the subsequent asphalt product production process can be effectively solved; the problem of asphalt and rubber powder performance reduction due to a conventional production method of obtaining the modified asphalt by degrading vulcanized rubber powder into asphalt at thehigh temperature above 200 DEG C through long-time shearing can be solved; the production period is shortened; the cost is reduced; in addition, the original crosslinking macromolecular reticular structure in the vulcanized rubber powder becomes smaller; a small number of chain type materials can be formed; the system sol content is increased; in the subsequent processing process, the substance exchange between the rubber powder and asphalt is facilitated; the compatibility and the stability are improved.

Owner:JIANGSU BAOLI INT INVESTMENT CO LTD +2

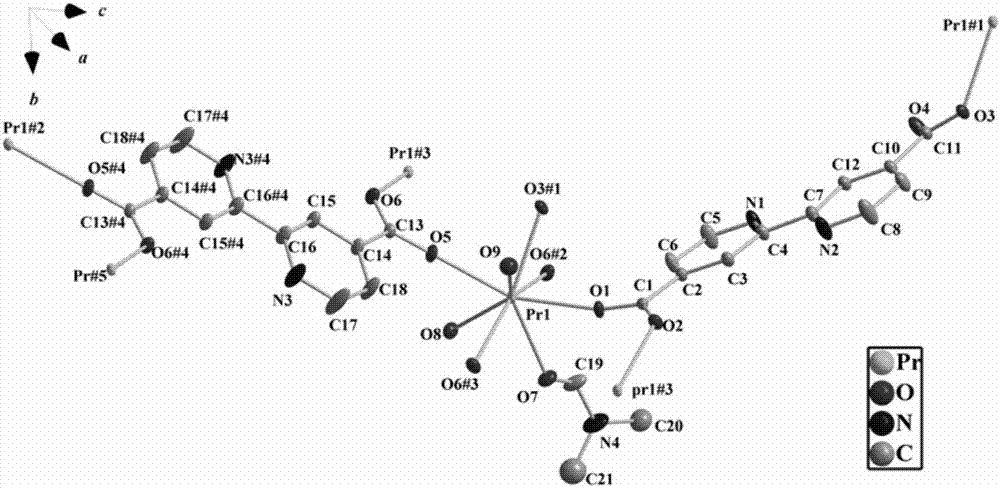

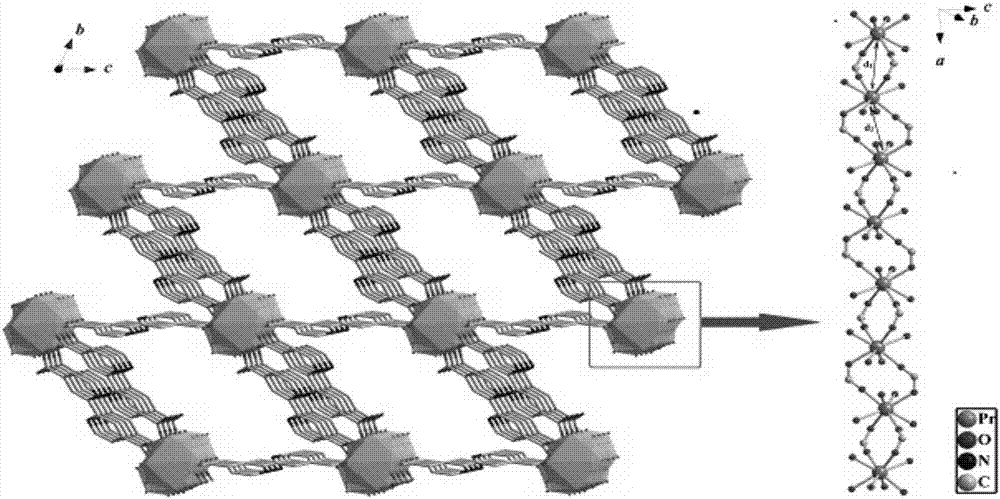

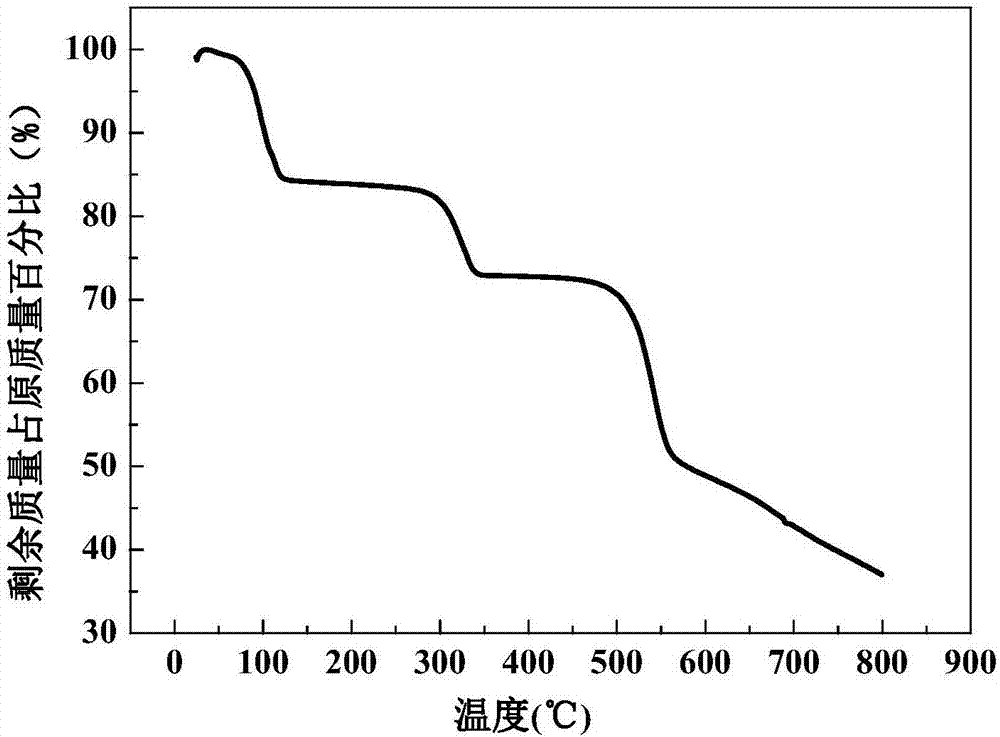

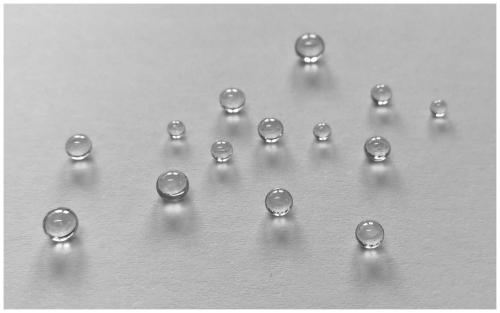

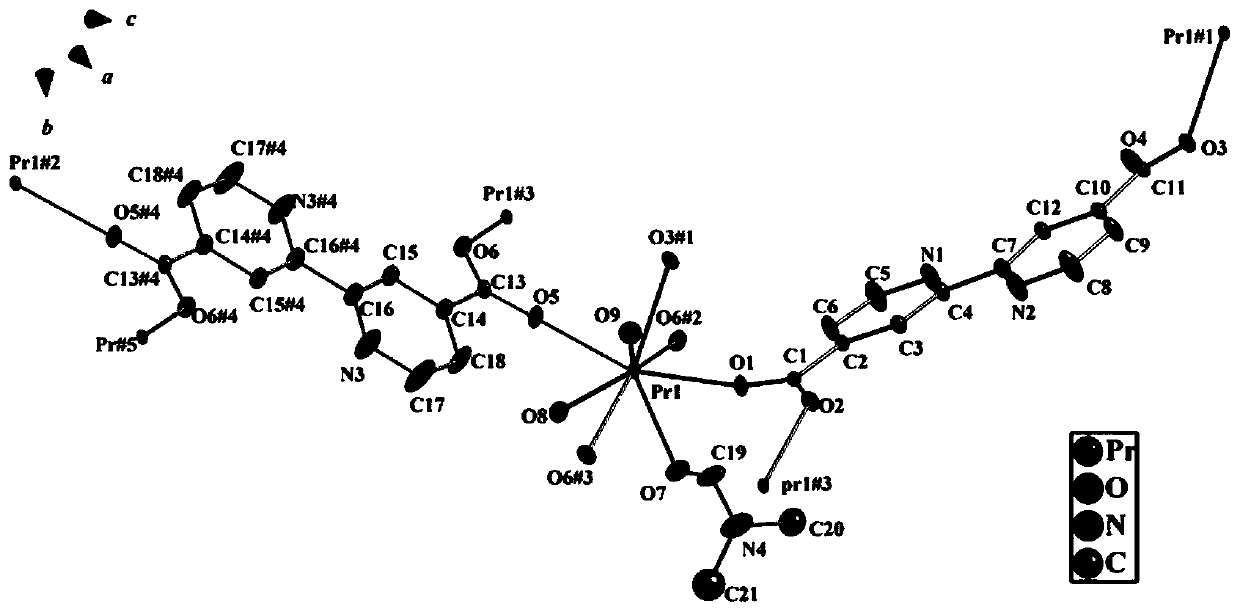

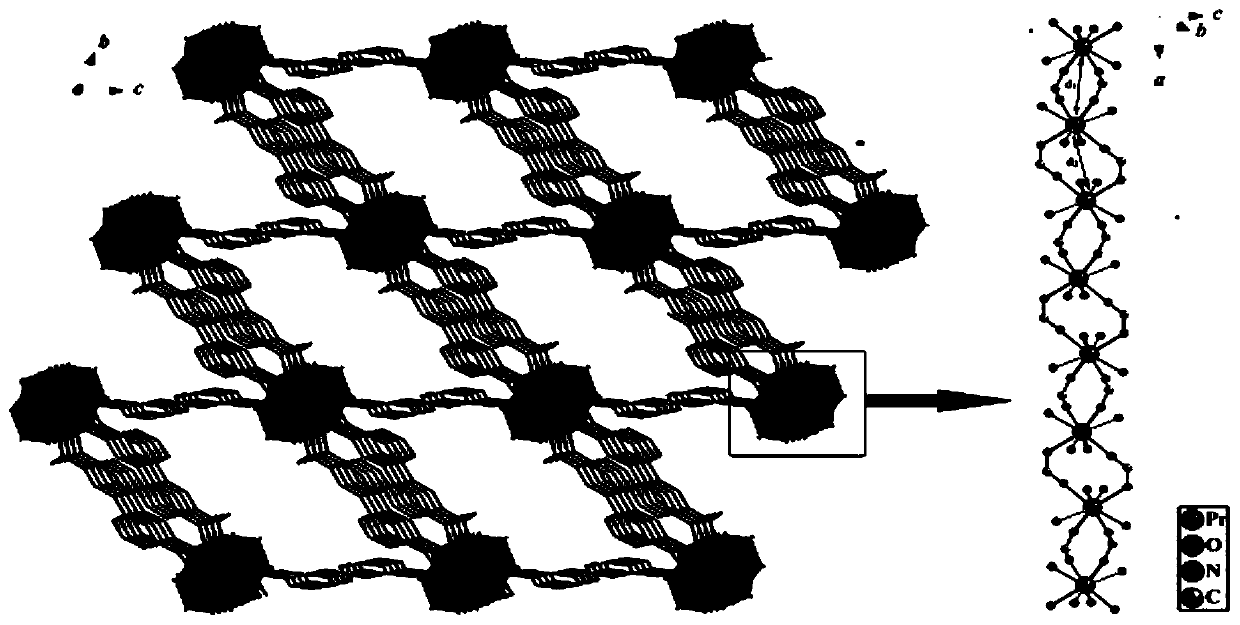

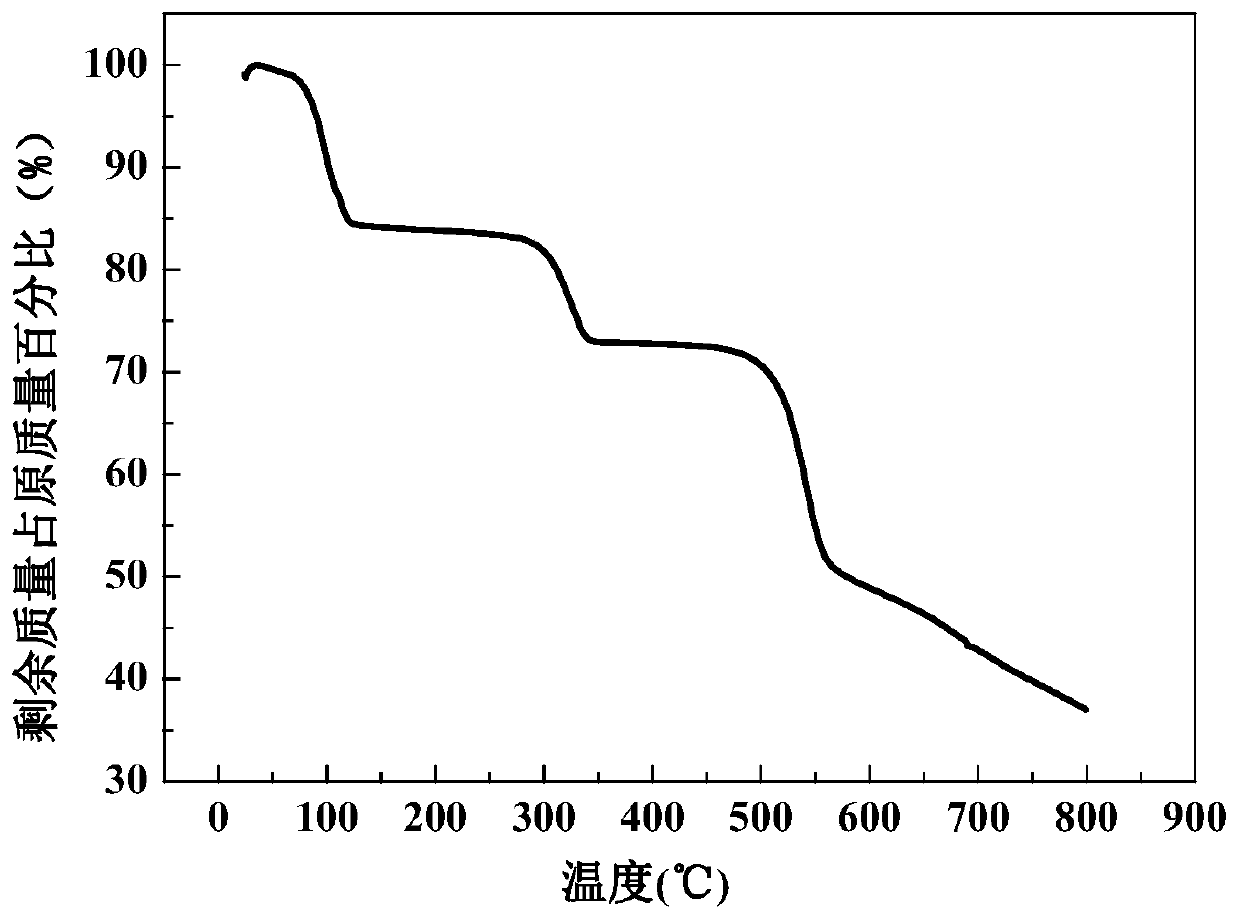

Novel rare-earth praseodymium complex with capability of effective photodegradation of azo dye, and preparation method and application of complex

ActiveCN107266477ASolve refractoryGood photocatalytic degradation of azo dyes (MB) performanceGroup 3/13 organic compounds without C-metal linkagesOrganic-compounds/hydrides/coordination-complexes catalystsN dimethylformamideCarboxylic acid

The invention belongs to the field of photocatalytic degradation of dyes, and particularly relates to a novel rare-earth praseodymium complex with capability of effective photodegradation of an azo dye, and a preparation method and an application of the complex. The preparation method comprises the steps pf introducing pyridine carboxylic acid aglucon with a coordination effect on a rare earth ion into a polymer side group, and then coordinating with Pr<3+> to form the novel rare-earth praseodymium complex with the capability of the photodegradation of the azo dye. A chemical formula of the complex is {[Pr(L<2>)1.5(DMF)(H2O)2](DMF)}n, wherein L<2> is a group of 2,2'-dipyridyl-4,4'-dicarboxylic acid with two protons removed; DMF is N,N-dimethylformamide; and n represents a natural number from 1 to positive infinity. The novel rare-earth praseodymium complex effectively solves the problem of the difficult degradation of the azo dye.

Owner:ANHUI NORMAL UNIV

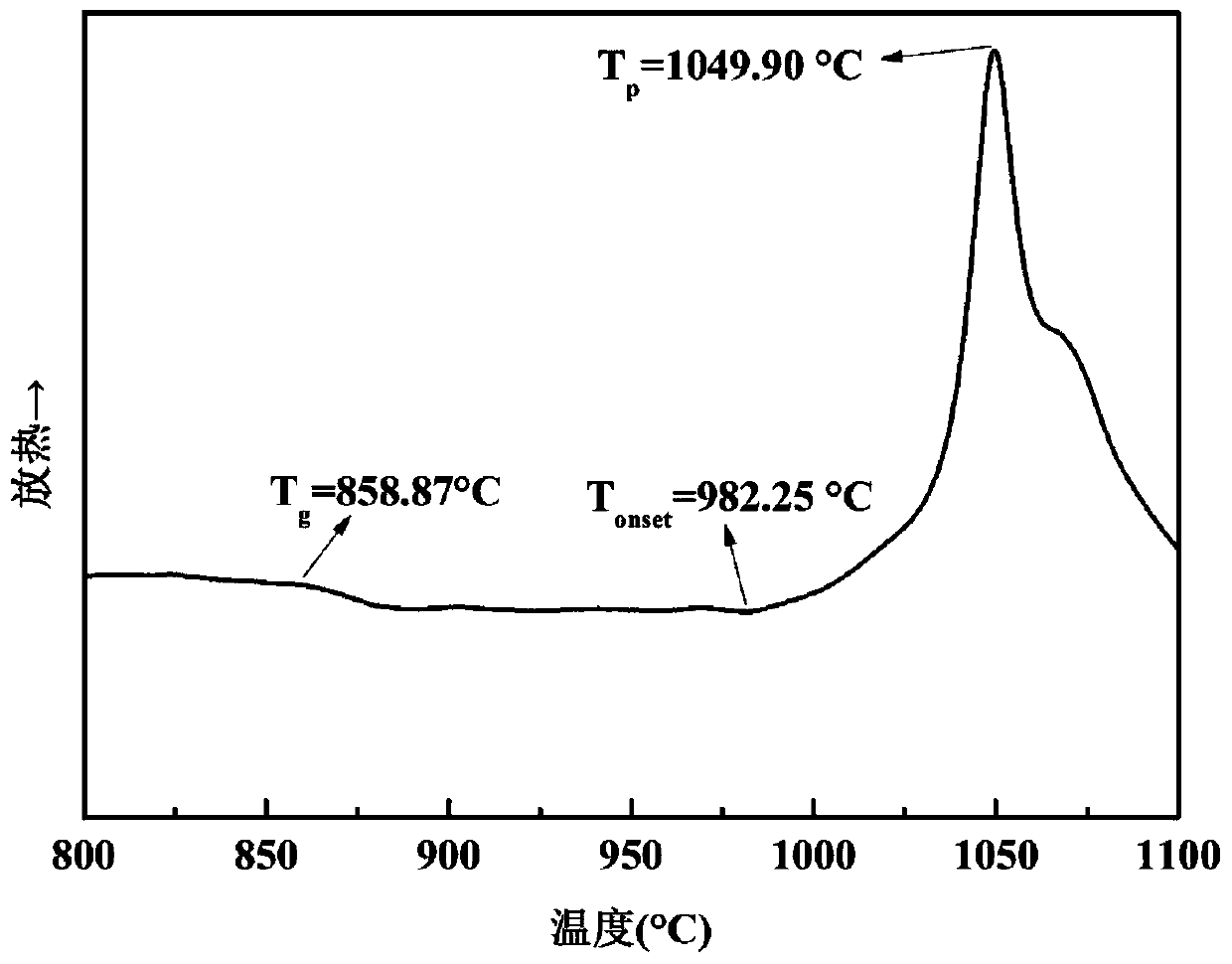

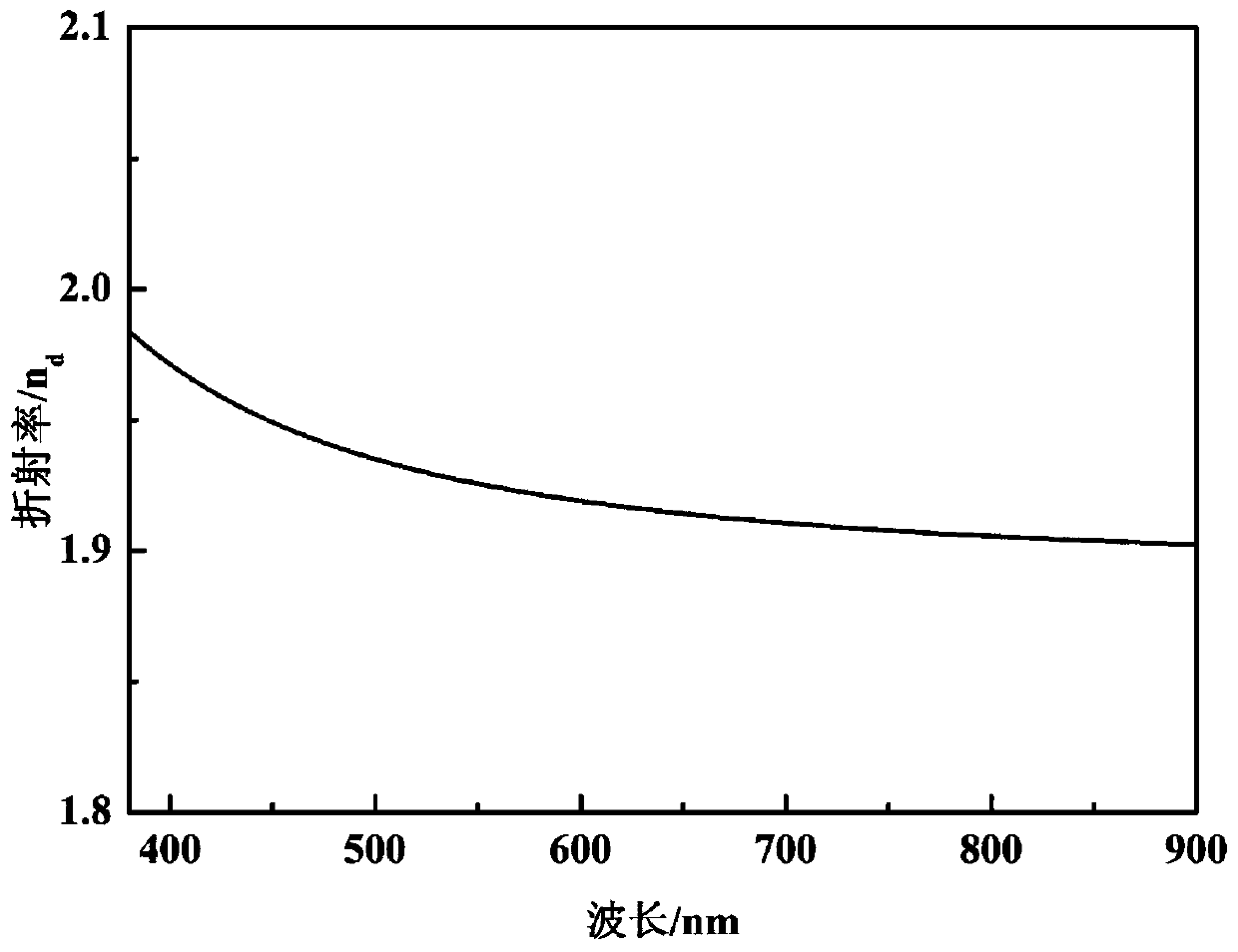

Colorless aluminate-niobate glass and preparation method and application thereof

The invention relates to aluminate-niobate glass and a preparation method and application thereof. The aluminate-niobate glass contains, by mol, 5-20% of Nb2O5, 20-65% of Al2O3, 10-60% of La2O3, 10-20% (not including 10%) of BaO, and 0-10% (not including 0) of other oxides. The problem is solved that high-refractivity glass has high melting temperature, proneness to crystal separation, poor stability and the like; the aluminate-niobate glass with high refractivity and low color dispersion can be attained.

Owner:WUHAN UNIV OF TECH

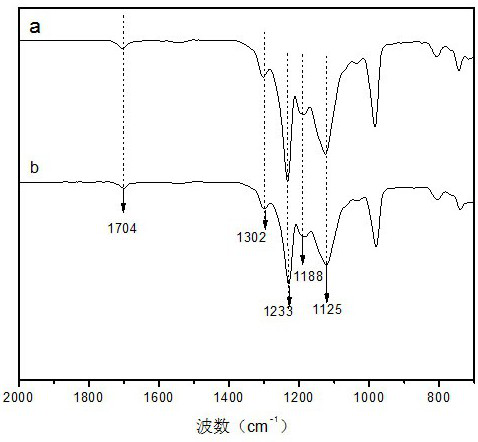

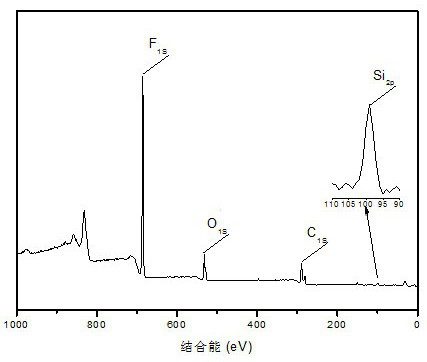

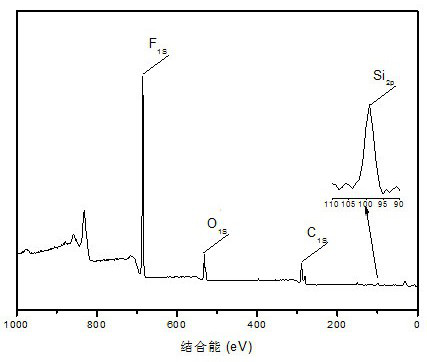

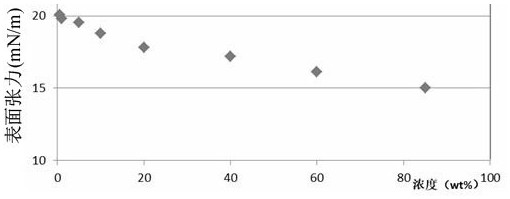

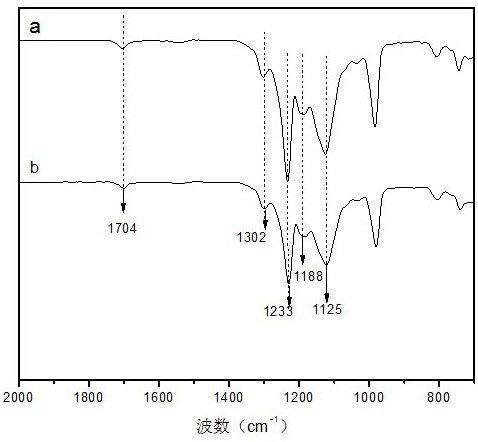

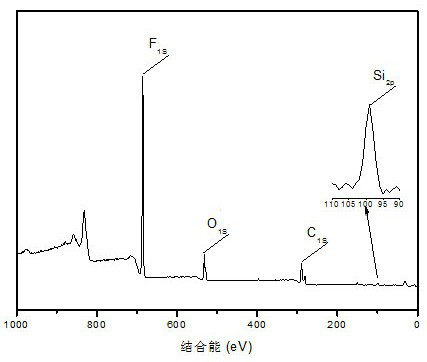

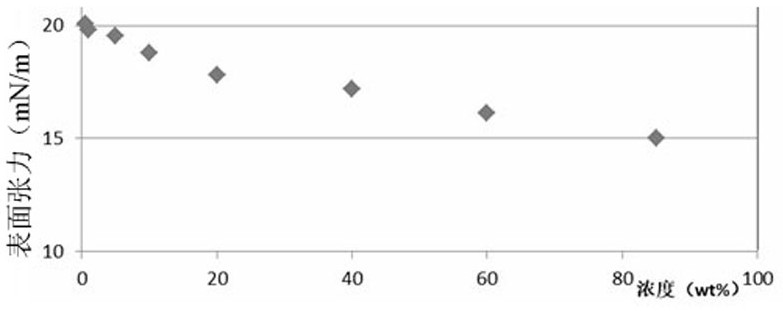

Gemini fluorine-containing surfactant as well as preparation method and application thereof

ActiveCN112691607ASolve refractoryAvoid cumulative toxicityTransportation and packagingMixingDouble bondActive agent

The invention relates to a gemini fluorine-containing surfactant as well as a preparation method and application thereof. Perfluoropolyether alcohol (PFPE-OH) reacts with halogenated allyl, and unsaturated double bonds are introduced; then a hydrosilylation reaction with methyl hydrogen dichlorosilane is carried out under the catalysis of platinum; the obtained intermediate product reacts with carbon magnesium polyethylene glycol monomethyl ether to generate perfluoropolyether-polyethylene glycol-methyl monochlorosilane (PFPE-SiCl-PEG); and further hydrolytic condensation is conducted to obtain the gemini fluorine-containing surfactant. The hydrophobic group adopted by the surfactant is perfluoropolyether, so that the problems that long-carbon-chain fluoroalkyl adopted by common perfluorooctane sulfonamide (PFOS), perfluorooctane sulfonic acid (PFOA) and other fluorosurfactants is difficult to degrade and accumulates toxicity are avoided, the hydrophobicity of the surfactant is easy to control by controlling the molecular weight of a perfluoropolyether chain segment, and the surfactant has very high hydrophobic efficiency. The gemini fluorine-containing surfactant provided by the invention is simple and convenient in preparation process, mild in reaction condition and suitable for industrial production, and only conventional equipment is needed in production.

Owner:SHENZHEN TAIKE TECH

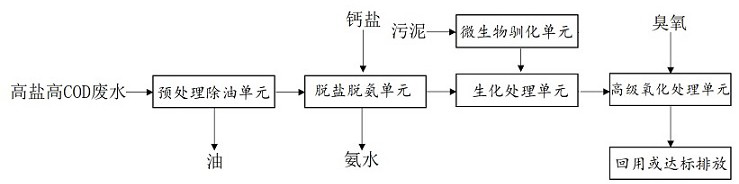

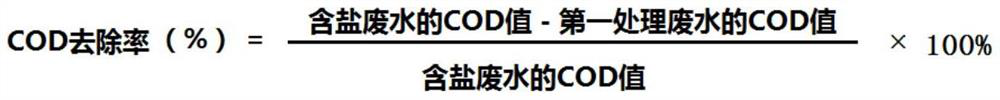

System and method for treating rare earth or nonferrous smelting high-salt and high-COD wastewater

InactiveCN113087319AReduce COD valueEfficient degradationFatty/oily/floating substances removal devicesWater contaminantsMicroorganismHalotolerance

The invention relates to a system and a method for treating rare earth or nonferrous smelting high-salt and high-COD wastewater, and belongs to the technical field of industrial high-salt wastewater treatment. The system comprises a pretreatment oil removal unit, a desalination and deamination unit, a sludge microorganism domestication unit, a biochemical treatment unit and an advanced oxidation treatment unit; an outlet of the pretreatment oil removal unit is connected with an inlet of the desalination and deamination unit; an outlet of the desalination and deamination unit and an outlet of the sludge microorganism domestication unit are connected with an inlet of the biochemical treatment unit; an outlet of the biochemical treatment unit is connected with an inlet of the advanced oxidation treatment unit. Through pretreatment oil removal, calcium salt desalination and deamination, sludge microorganism domestication, biochemical treatment and advanced oxidation treatment, on one hand, the salinity of the wastewater is reduced, ammonium is recycled, on the other hand, sludge microorganisms are domesticated, the salt tolerance of the sludge microorganisms is improved, and therefore the high-salt and high-COD wastewater can be treated through a biochemical method; on the basis of biochemical treatment, an advanced oxidation method is adopted for advanced treatment, and finally, the high-salt and high-COD wastewater can be recycled or discharged after reaching the standard.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

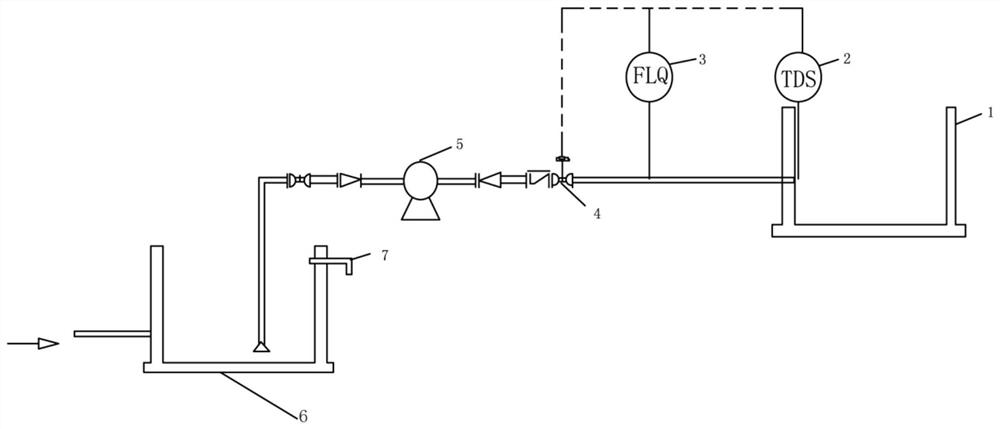

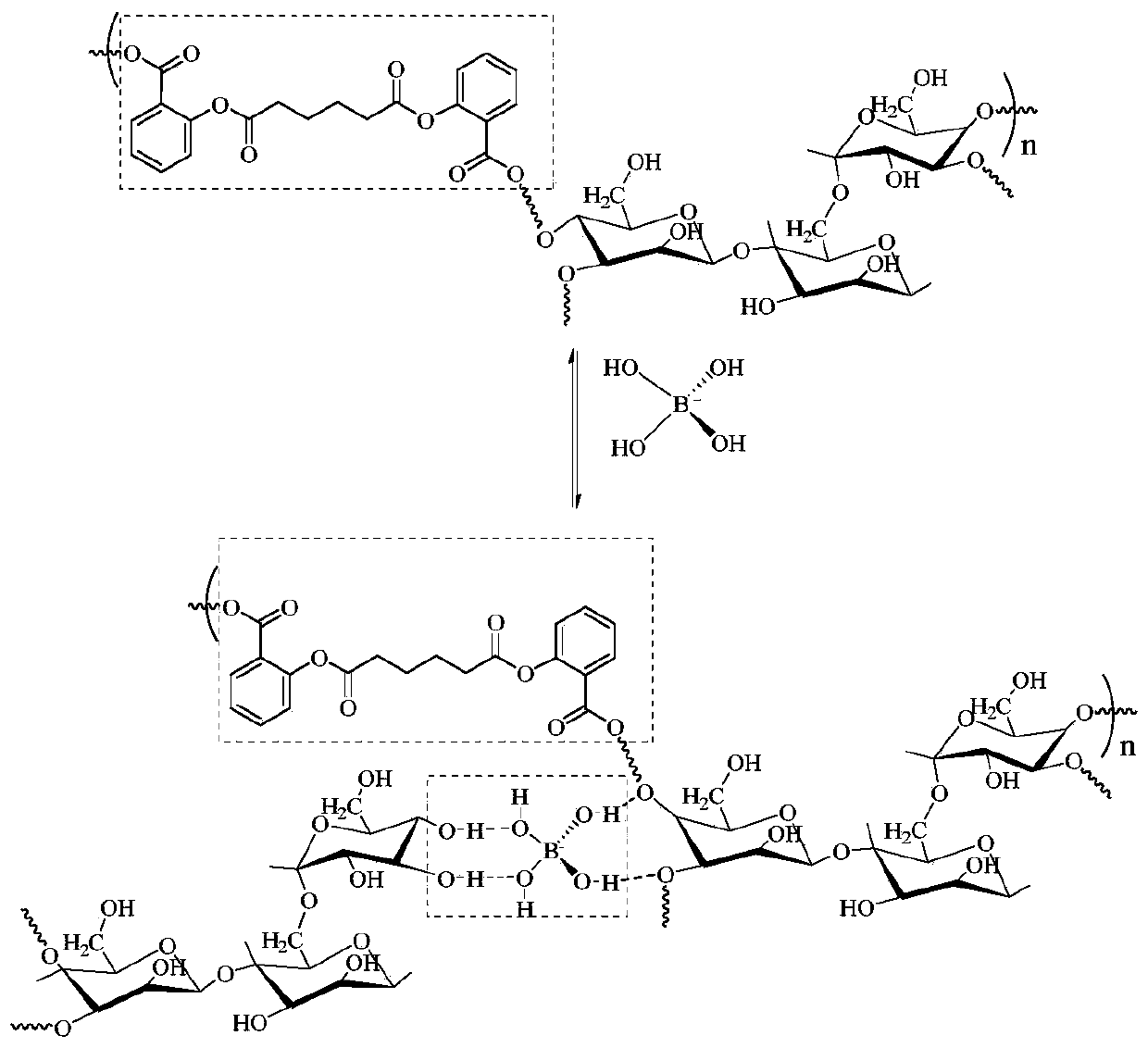

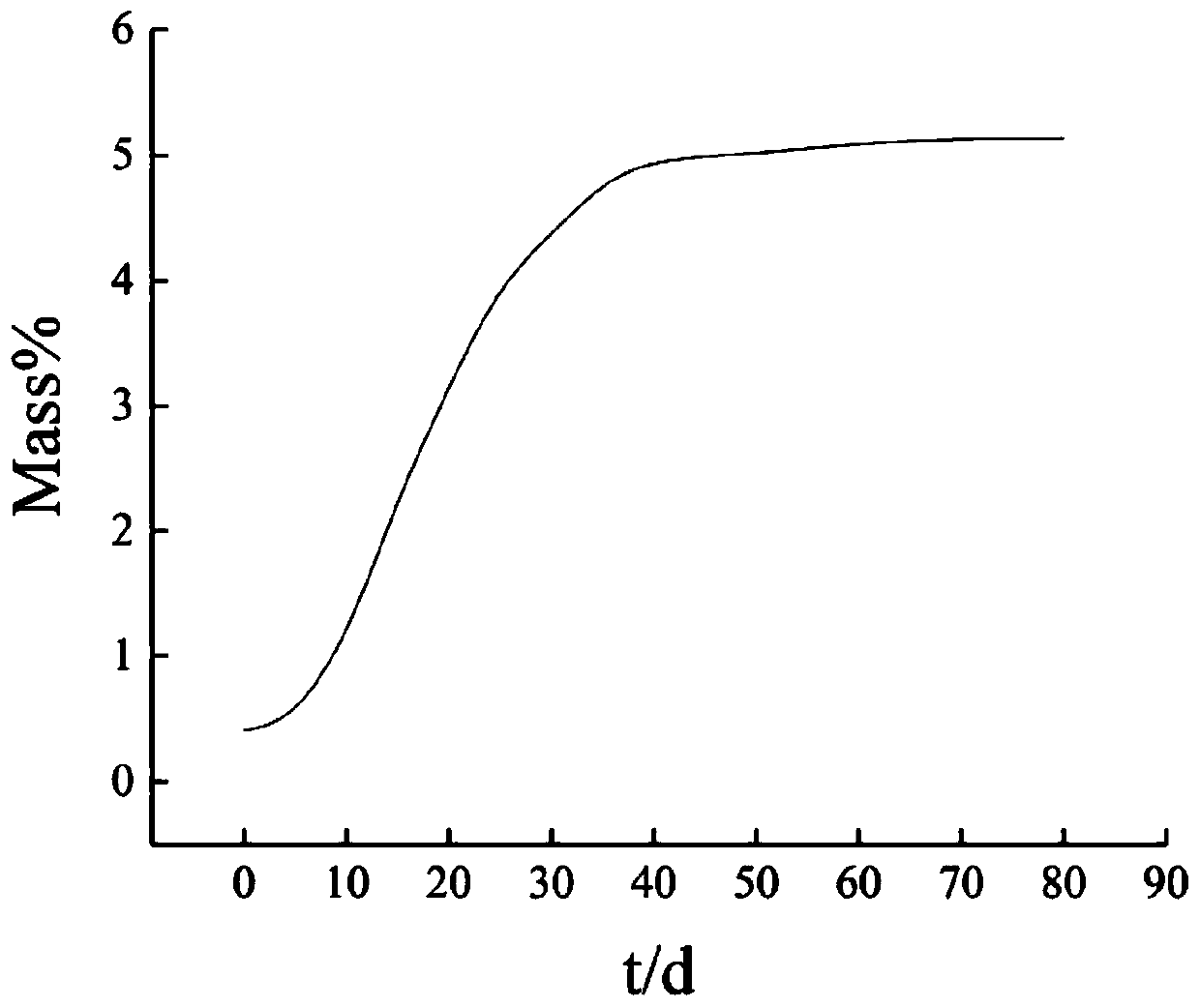

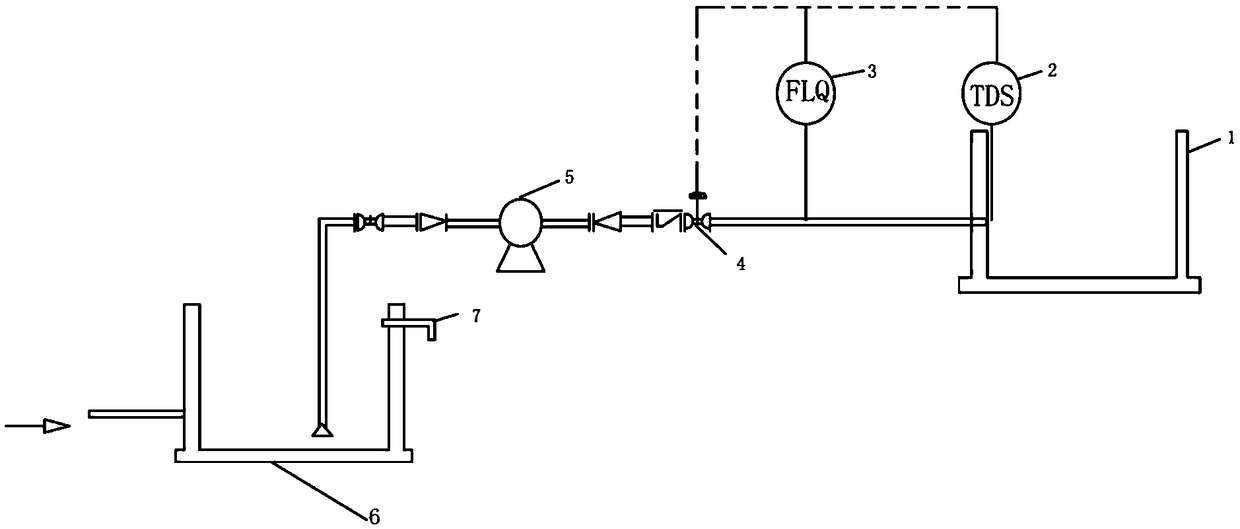

Method and system for treating saline wastewater

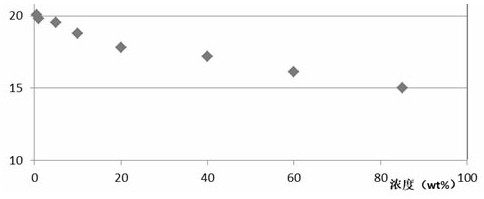

ActiveCN108751434BImprove flow acclimation activitySolve refractoryWater treatment parameter controlBiological water/sewage treatmentActivated sludgeAmmoniacal nitrogen

The present invention provides a method and system for treating saline wastewater. The method of the present invention comprises: making saline wastewater flow through activated sludge containing halophilic bacteria, using the activated sludge to perform desalination pretreatment on the saline wastewater to obtain the first treated wastewater, and gradually increasing the saline wastewater during the desalination pretreatment process Flow rate, to measure the TDS value of saline wastewater at different flow rates; to measure the water quality parameters of the first treated wastewater, each water quality parameter has a corresponding preset range, and the TDS value under the flow rate corresponding to each water quality parameter value that meets the preset range Set as the first TDS optimal value group; adjust the flow of saline wastewater into the activated sludge, so that its TDS value reaches the range covered by the first TDS optimal value group, so as to continue desalination treatment of saline wastewater, water quality Parameters include COD and / or ammonia nitrogen content. The method and system of the invention can realize economical and effective removal of pollutants in saline wastewater.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A kind of adsorption treatment method of cationic dye

InactiveCN106698581BImprove adsorption capacitySolve refractoryOther chemical processesWater contaminantsMethyl violetBrilliant Red

The invention relates to an adsorption treatment method for cationic dye. The adsorption treatment method for the cationic dye comprises the following steps: firstly utilizing water to classify lignin into a water soluble fraction and a water insoluble fraction, then utilizing a ketone solvent to classify the water insoluble lignin fraction into a ketone soluble fraction and a ketone insoluble fraction again, and using the finally obtained water insoluble and ketone insoluble fraction for adsorbing and separating cationic dye methylene blue, cationic brilliant red, crystal violet, methyl violet and the like. The dissolution classification method only relates to dissolution classification of lignin and does not relate to chemical modification, so that the method provided by the invention has the advantages of simple technology and low cost; and water and the ketone solvent used for dissolution classification can be repeatedly utilized by recycling, and no consumption or loss is produced, so that the method provided by the invention has the advantage of being environment-friendly.

Owner:HEBEI UNIV OF TECH

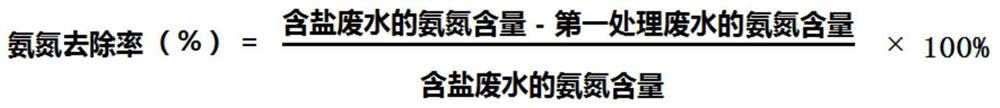

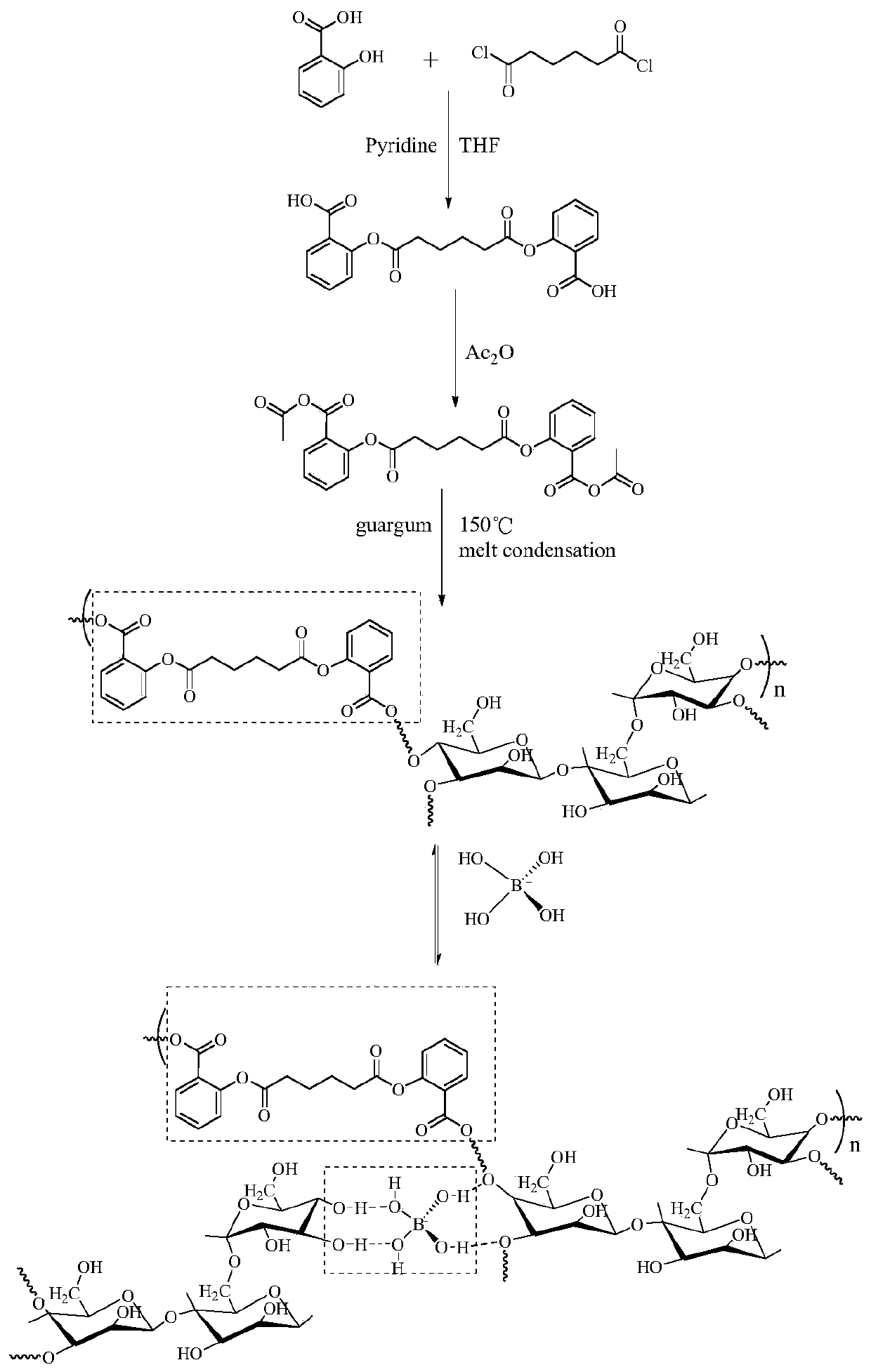

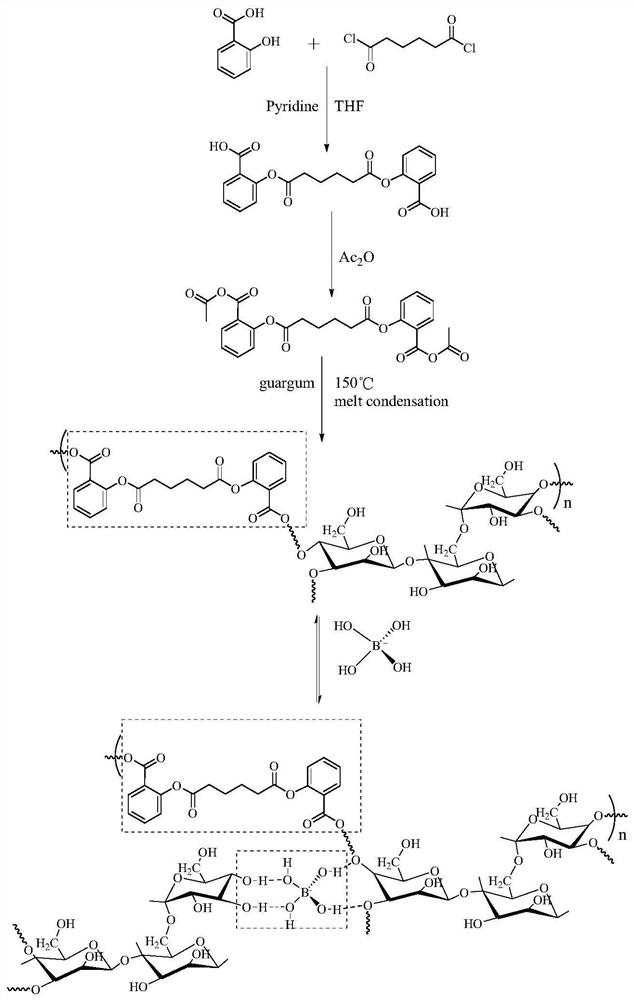

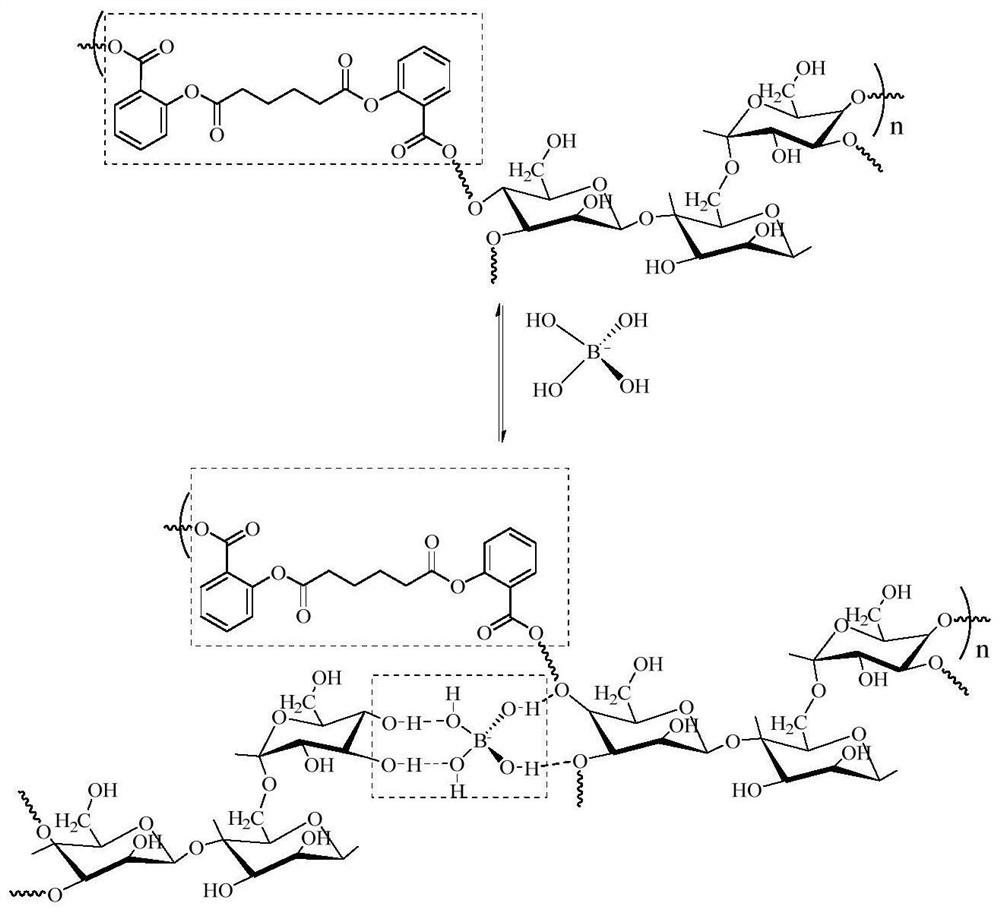

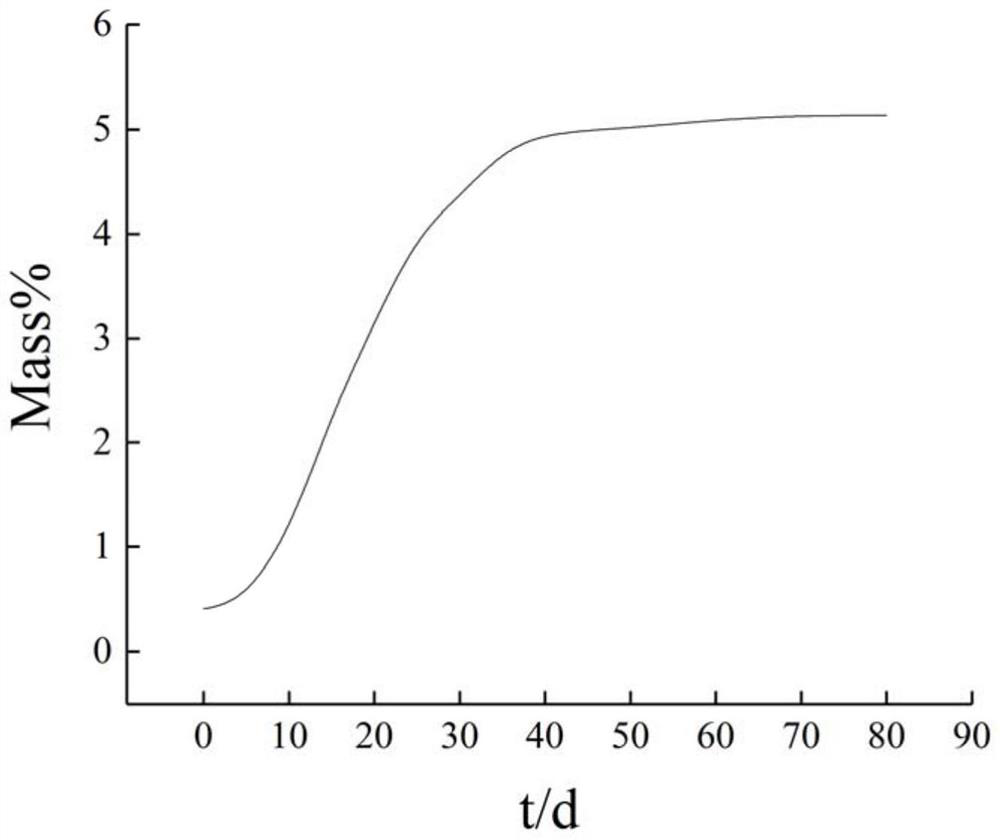

Degradable double-slow-release water-retaining fertilizer with strong water absorption and preparation method thereof

ActiveCN111296446ASolve refractoryControl releasePlant growth regulatorsBiocideAcetic anhydridePtru catalyst

The invention discloses a degradable double-slow-release water-retaining fertilizer with strong water absorption and a preparation method thereof. The preparation method comprises the following steps:(1) dissolving salicylic acid and a solvent in a three-neck flask, adding adipoyl chloride and an acid-binding agent into the flask by using a constant-pressure dropping funnel, carrying out a chainextension reaction process at 140-160 DEG C, and carrying out reduced pressure distillation and vacuum drying after the reaction is completed, so as to obtain an intermediate I, (2) mixing the intermediate I with acetic anhydride, adding a catalyst, reacting at 105-110 DEG C, and carrying out cooling, crystallizing, suction filtration and washing with cold water to obtain a crude product, and recrystallizing to obtain an intermediate II, (3) making the intermediate II react with guar gum at 140-160 DEG C, and carrying out melt polycondensation to obtain the product, and (4) preparing the product into a solution, adding a borax solution to form gel, and carrying out freeze-drying and crushing. The degradable double-slow-release water-retaining fertilizer with strong water absorption can beused for double slow release of salicylic acid and boric acid, and can be used as a plant fertilizer for reducing salt damage to various plants.

Owner:内蒙古中孚明丰农业科技有限公司

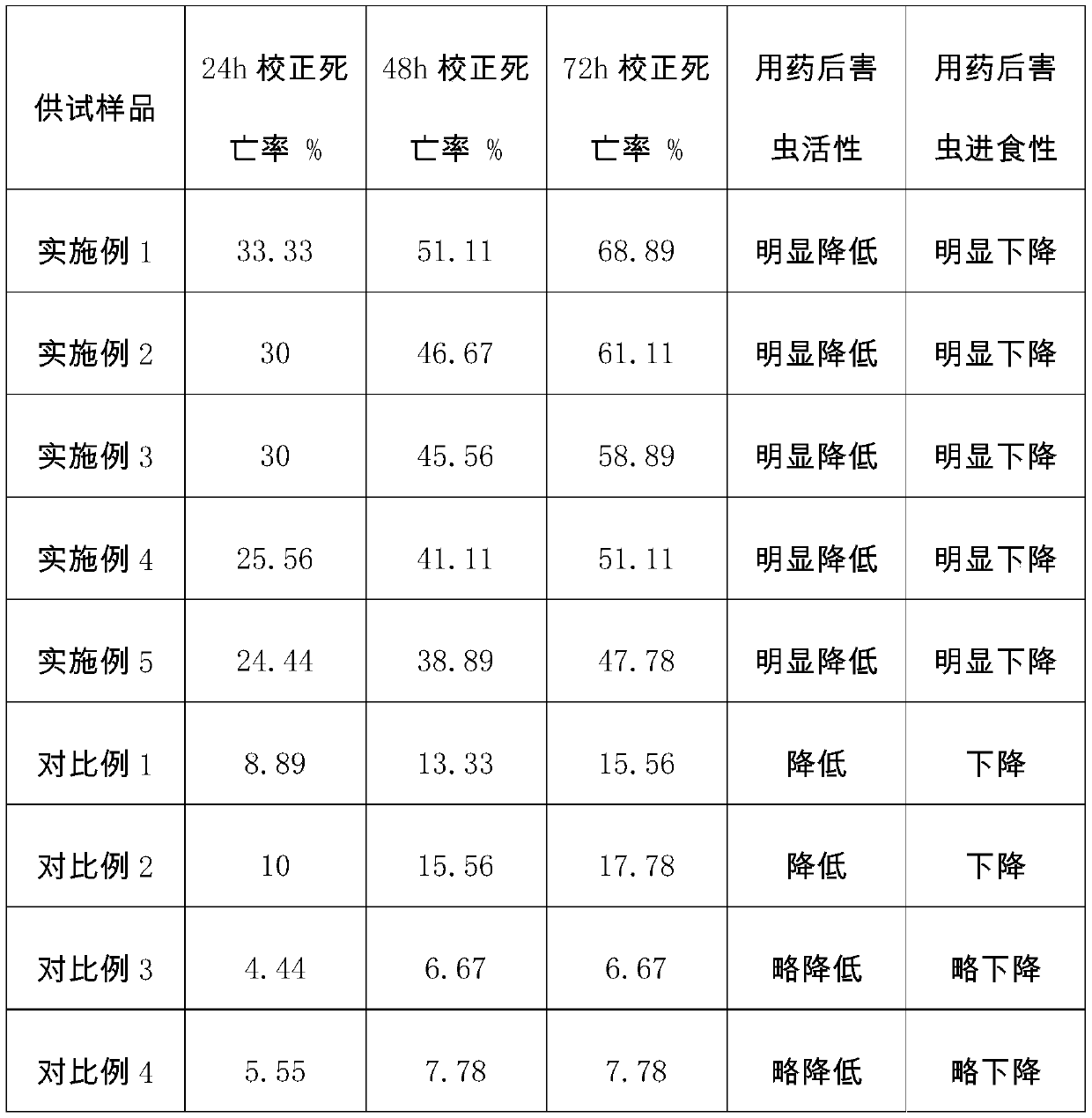

A kind of insecticide containing tea saponin and preparation method thereof

ActiveCN107484778BReduce pollutionAvoid it happening againBiocideAnimal repellantsChemical synthesisFood chain

The invention discloses an insecticide containing tea saponin. The insecticide is prepared from the following components in percentage by weight: 1.5%-2.0% of tea saponin, 0.8%-1.2% of an arenaria rhodantha extract, 1.0%-1.3% of a surfactant and the balance of a solvent. The invention further provides a preparation method of the insecticide. The effective components of the insecticide are extracted from camellia seed cakes and arenaria rhodantha, and the insecticide, which is a botanical insecticide, is environment-friendly with low environmental pollution. Compared with that of chemical insecticides, the preparation method is simple, and does not generate a large number of degradation-resistant toxic chemical substances generated in chemical synthesis; the insecticide is easily biodegradable, so that residual pesticides on plants are greatly reduced, and the damage caused by a bioconcentration effect on human health through a food chain is avoided; and by virtue of combined use of the tea saponin and the arenaria rhodantha extract, the killing capacity to tea shoot borers is obviously enhanced, the food refusal and the contact toxicity are caused to tea shoot borers, and the killing rate within 72h can reach 65% or above.

Owner:三江县稻香山茶油生态发展有限公司

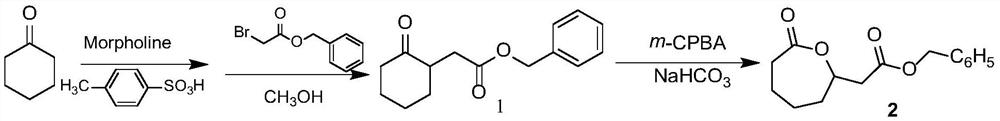

A kind of water purifying agent for industrial waste water and preparation method thereof

ActiveCN112456624BHigh densityPromote formationWater treatment parameter controlWater/sewage treatment using germicide/oligodynamic-processIndustrial waste waterCaprolactone

This case relates to a water purifying agent for industrial wastewater and a preparation method thereof. Each 100 parts of the water purifying agent includes the following raw materials in parts by mass: 30-40 parts of modified starch, 3-8 parts of carboxylated nanocellulose , 4-8 parts of polysilicate, 8-15 parts of attapulgite, 3-6 parts of biological sterilizing agent and the balance of water; wherein, the modified starch is caprolactone graft modified corn starch, An amide bond is attached to the graft chain. The invention uses caprolactone as the bridge connecting the amide bond with the corn starch to provide cohesion-flocculation for the polymer starch; the carboxylated nanocellulose is also a natural polymer with a structure similar to that of starch, which can assist the modified starch to promote The flocs settle quickly, and its nano-size effect helps to load the biological sterilizer, which further reduces COD and improves the sterilization performance; polysilicate and attapulgite are used together as inorganic substances to further improve the adsorption and flocculation performance. , to achieve the effect of comprehensive management.

Owner:YANGZHOU POLYTECHNIC INST

Environment-friendly paper-based material for radio frequency tag antenna and manufacturing method of environment-friendly paper-based material

InactiveCN114214873ANo pollutionEasy to evaporateNon-fibrous pulp additionSpecial paperProtein solutionRadio frequency

The invention discloses an environment-friendly paper-based material for a radio frequency tag antenna and a manufacturing method, the paper-based material is prepared by paper adsorbing natural alcohol-soluble or ester-soluble protein, the manufacturing method of the paper-based material comprises the following steps: step 1, preparing a protein solution, and preparing protein and a solvent into the protein solution; step 2, adsorbing paper with the protein solution prepared in the step 1; and step 3, drying the paper adsorbing the protein solution in the step 2 until the solvent is evaporated and the protein is solidified or denatured. Natural protein is used during waterproof modification treatment of the paper, artificial synthetic resin is replaced, the paper is subjected to infiltration, roller coating or spraying, then a solvent is dried and evaporated to solidify the protein, the paper is waterproof after being modified and is easy to degrade in the natural environment, meanwhile, the protein can be decomposed by microorganisms, and the water resistance of the paper is improved. Even if the treated paper is eaten by animals, the paper does not harm the animals.

Owner:陆凤生 +1

A Strain of Stenotrophomonas Efficiently Degrading Polybutylene Terephthalate/Adipate and Its Application

The invention provides a strain of Stenotrophomonas that efficiently degrades polybutylene terephthalate / adipate and the application thereof. The present invention isolates and screens a PBAT-degrading bacterium that can secrete lipase, Stenotrophomonas sp.strain YCJ1, from the soil of Yanxia Town, Liquan County, Shaanxi Province, and names it Stenotrophomonas sp. Species Collection and Management Center, the deposit number is CGMCC 18059. The advantage of the present invention is that the bacterium can secrete lipase and efficiently degrade PBAT, and the bacterium has a better degradation effect under alkaline conditions, and the Stenotrophomonas and its lipase can be used as enzyme preparations and biological agents It has a good application value when applied to the environmental remediation of PBAT and PBAT-based biodegradable materials in alkaline environment.

Owner:内蒙古颐祥杰成科技有限责任公司

A kind of Gemini type fluorosurfactant and its preparation method and application

ActiveCN112691607BSolve refractoryAvoid cumulative toxicityTransportation and packagingMixingPolymer scienceActive agent

The present invention relates to a gemini-type fluorine-containing surfactant and its preparation method and application. The perfluoropolyether alcohol (PFPE‑OH) is reacted with a halogenated allyl group to introduce an unsaturated double bond; Methylhydrogendichlorosilane undergoes a hydrosilylation reaction; the intermediate product obtained reacts with carbon magnesium polyethylene glycol monomethyl ether to generate perfluoropolyether-polyethylene glycol-methyl monochlorosilane (PFPE- SiCl‑PEG); further hydrolysis and condensation to obtain a gemini-type fluorosurfactant. The hydrophobic group used in the surfactant of the present invention is perfluoropolyether, which not only avoids the long carbon chain fluorine used in commonly used fluorosurfactants such as perfluorooctanesulfonamide (PFOS) and perfluorooctanesulfonic acid (PFOA). The alkyl group is refractory to degradation and cumulative toxicity, and its hydrophobicity can be easily adjusted by controlling the molecular weight of the perfluoropolyether chain segment, and has very high hydrophobicity. The preparation process of the gemini type fluorine-containing surfactant of the present invention is simple and convenient, the reaction condition is mild, the production only needs conventional equipment, and is suitable for industrialized production.

Owner:SHENZHEN TAIKE TECH

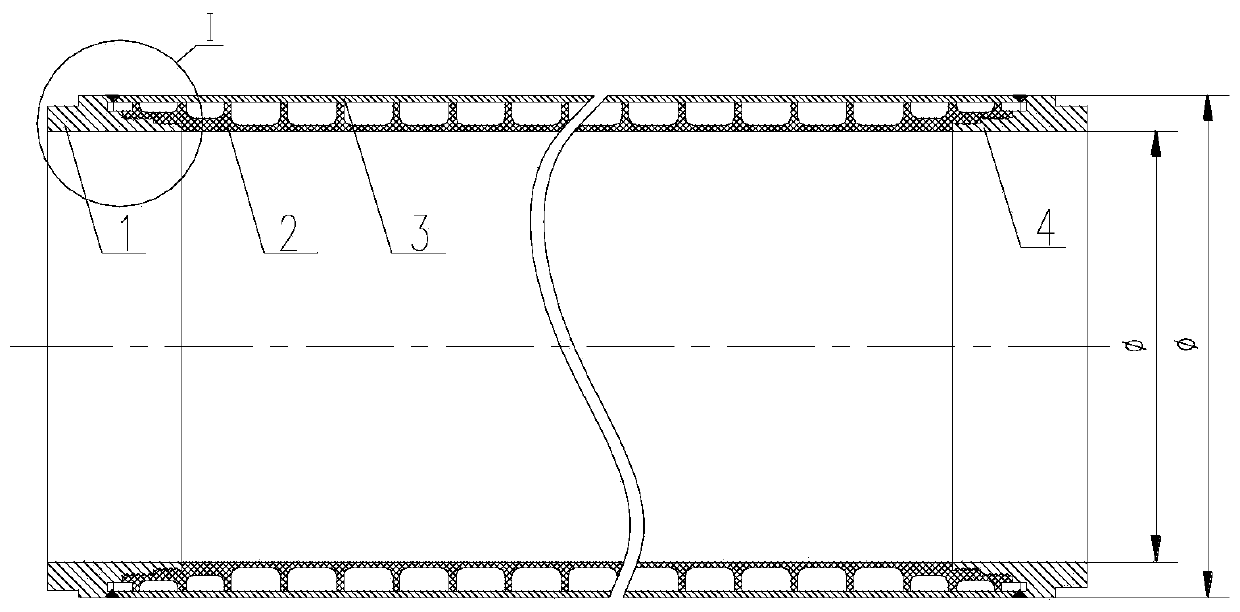

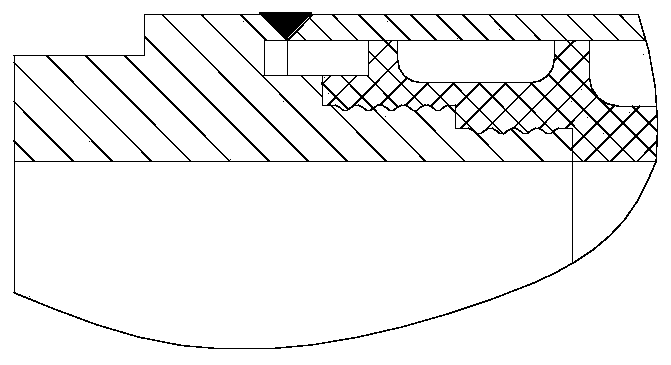

Pressure-resistant structure of deep submersible

ActiveCN110217336BIncreased ability to withstand external water pressureStrong resistance to seawater corrosionNon-magnetic metal hullsPull forceButt joint

The invention relates to a pressure-resistant structure of a large-depth submersible. The pressure-resistant structure is of a combined structure form, and comprises an inner shell, an outer shell, aleft flange and a right flange, wherein the inner shell is of a main force bearing structure, the inner shell is formed by winding on the basis of the left flange and the right flange, the outer shellis formed by rolling a titanium alloy plate and welding the titanium alloy plate through a longitudinal weld joint and is tightly attached to an inner shell ring rib, and the outer shell is connectedwith the left flange and the right flange through circumferential weld joints at the two ends. The inner shell is of a cylinder and outer ring rib structure, outer ring ribs are distributed at equalintervals, and the specific intervals are optimally configured according to the minimum stress criterion of a pressure-resistant structure when external pressure is borne. The inner shell and the outer shell are connected through the butt joint circumferential weld joint, the weld joint only bears tension and pressure, and the stress form is simple. The submersible has a large-depth pressure-resistant structure which is high in underwater pressure resistance, good in pressure-resistant stability, uniform in pressure-resistant stress, light in weight, high in specific strength, good in impact resistance, long in seawater corrosion resistance duration, long in service life, non-magnetic and good in concealment.

Owner:海南中控科技有限公司

Method and system for processing salt containing wastewater

ActiveCN108751434AImprove flow acclimation activitySolve refractoryWater treatment parameter controlBiological water/sewage treatmentValue setSludge

The invention provides a method and system for processing salt containing wastewater. The method comprises following steps: making salt containing wastewater go through active sludge containing salt eating bacteria to use the active sludge to carry out a desalination pretreatment to obtain first processed wastewater, wherein during the desalination pretreatment process, the salt containing wastewater flow is gradually increased, and TDS values of the salt containing wastewater are measured under different flows; measuring the water quality parameters of the first processed wastewater, whereineach water quality parameter has a corresponding preset range, and the TDS value of the corresponding flow, when all water quality parameters are in the present ranges is set to be a first TDS optimized value set; adjusting the flow of salt containing wastewater that is introduced into the active sludge until the TDS value corresponding to the flow of salt containing wastewater falls into the range of the first TDS optimized value set, and carrying on a desalination treatment on salt containing wastewater, wherein the water quality parameters comprises COD and / or ammonia nitrogen content. Theprovided method and system can economically and effectively remove pollutants in salt containing wastewater.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A high-glue asphalt masterbatch and its low-temperature and environmentally friendly production process

ActiveCN109810521BRealize environmentally friendly useShorten the production cyclePlastic recyclingBuilding insulationsPolymer scienceVulcanization

The invention relates to a high-glue asphalt masterbatch and its low-temperature environment-friendly production process. The raw materials include the following components and weight percentages: vulcanized rubber powder: 10-50; deconstructing agent: 5-15; base asphalt: 40-80; The above-mentioned high rubber asphalt masterbatch is a homogeneous blend obtained by first desulfurizing and degrading vulcanized rubber powder in a deconstructing agent, and then adding base asphalt and blending together. Utilizing the high-glue asphalt masterbatch of the present invention can effectively solve the problems of high odor and substandard emissions in the subsequent production of asphalt products; it can also avoid the conventional degradation of vulcanized rubber powder after long-term shearing at high temperatures above 200°C The performance of both asphalt and rubber powder is reduced due to the production method of obtaining modified asphalt from asphalt, which shortens the production cycle and saves costs, and the original cross-linked macromolecular network structure in vulcanized rubber powder becomes Smaller, forming a small amount of chains and increasing the sol content of the system, which is conducive to the material exchange between rubber powder and asphalt during subsequent processing, and improves compatibility and stability.

Owner:JIANGSU BAOLI INT INVESTMENT CO LTD +2

Method for preparing fluoropolyolefin based on gemini type fluorosurfactant

The invention relates to a method for preparing fluoropolyolefins based on a gemini-type fluorosurfactant. In the presence of an initiator and a gemini-type fluorosurfactant, the monomer fluoroolefin is used as a raw material for polymerization reaction to prepare a fluoroolefin polymer ;Use perfluoropolyether-polyethylene glycol-methyl monochlorosilane (PFPE-SiCl-PEG) to hydrolyze and condense to obtain a gemini-type fluorosurfactant, which is directly bonded by an ether bond (-O-) to make Two hydrophobic segments and two hydrophilic segments are tightly coupled to form a compact gemini surfactant structure, which provides excellent surface activity. The fluorine-containing surfactant provided by the invention is applied to the dispersion polymerization of fluoroolefins. The monomer fluoroolefins have strong dispersion in the water phase, and the solid content of a single polymerization tank can reach 25% to 32%, which has the advantage of high productivity.

Owner:SHENZHEN TAIKE TECH

Manufacturing method of paint for mechanical equipment

InactiveCN107129726AReduce pollutionLow costAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyLacquer

The invention discloses a manufacturing method of paint for mechanical equipment. The method includes the steps: firstly, stirring raw lacquer and expandable polystyrene foams in an oxidation polymerization machine to obtain first polymers; secondly, adding low-level ester organic matters, dispersing agents, plasticizers, modified epoxide resins and polyurethane emulsion into a stirrer, adding the first polymers acquired in the step 1, and sufficiently and uniformly stirring mixture to obtain second mixture; thirdly, adding linseed oil serving as dilute solvents into the second mixture, and kneading mixture in a vacuum kneading machine to obtain third mixture; fourthly, adding preservative into the third mixture, uniformly mixing and stirring mixture in a mixer by heating at low temperature, cooling the mixture to the normal temperature to obtain finished products. The prepared paint has higher corrosion resistance, water resistance and oxidation resistance and is low in cost and simple in preparation method.

Owner:合肥博创机械制造有限公司

Rare earth praseodymium complex for efficient photodegradation of azo dyes, preparation method and application thereof

ActiveCN107266477BSolve refractoryImprove stabilityGroup 3/13 organic compounds without C-metal linkagesOrganic-compounds/hydrides/coordination-complexes catalystsN dimethylformamideCarboxylic acid

The invention belongs to the field of photocatalytic degradation of dyes, and specifically relates to a new type of rare earth praseodymium complex that can effectively photodegrade azo dyes and its preparation method and application. This preparation method introduces a pyridine carboxylic acid-type ligand that has coordination effects on rare earth ions into the polymer side group, and then combines it with Pr 3+ Coordinated to obtain a new type of rare earth praseodymium complex that photodegrades azo dye dye. The chemical formula of this complex is {[Pr(L 2‑ ) 1.5 (DMF)(H 2 O) 2 ](DMF)} n , in the formula: L 2‑ It is the group after removing two protons from 2,2'-bipyridyl-4,4'-dicarboxylic acid. DMF is N,N-dimethylformamide, and n represents a natural number from 1 to positive infinity. The new rare earth praseodymium complex effectively solves the problem of difficult degradation of azo dyes.

Owner:ANHUI NORMAL UNIV

A kind of degradable and strong water absorption double slow-release water-retaining fertilizer and preparation method thereof

ActiveCN111296446BControlled slow releaseReduce salt damagePlant growth regulatorsBiocideAcetic anhydridePtru catalyst

The invention discloses a degradable strong water-absorbing double slow-release water-retaining fertilizer and a preparation method thereof. The preparation method comprises: (1) dissolving salicylic acid and a solvent in a three-necked flask, and using a constant-pressure dropping funnel to dissolve adipoyl chloride Add the acid-binding agent into the flask, carry out the chain extension reaction at 140-160°C, distill under reduced pressure after the reaction is completed, and dry in vacuum to obtain the intermediate I; (2) mix the intermediate I with acetic anhydride, add the catalyst, and React at 105-110°C, cool and crystallize, filter with suction, wash with cold water to obtain a crude product, and recrystallize to obtain intermediate II. (3) React intermediate II with guar gum at 140-160° C. for melt polycondensation to obtain a product. (4) The product is configured into a solution, and a borax solution is added to form a gel, which is freeze-dried and pulverized. The degradable strong water-absorbing double slow-release water-retaining fertilizer can double slow-release salicylic acid and boric acid, and can be used as a plant fertilizer to reduce salt damage to various plants.

Owner:内蒙古中孚明丰农业科技有限公司

Alternating Ultrasonic Field Assisted Narrow Gap Welding Method

ActiveCN113070595BIncrease energy densityStrong penetrating powerWelding apparatusEngineeringArc energy

The invention discloses a narrow-gap welding method assisted by alternating ultrasonic fields, which includes 1) placing a processed workpiece on a welding platform, making a groove on the workpiece to be welded, pressing the four corners tightly, and placing the workpiece on both sides above the groove respectively. An ultrasonic device, the lower ends of the ultrasonic generators point to the opposite side of the groove, and the electrodes are arranged in the middle of the two ultrasonic devices; 2) welding, the left and right ultrasonic devices work alternately to make the arc swing left and right; 3) during the welding process, adjust the ultrasonic device Power and frequency parameters, change the arc deflection range, so that the arc parameters are reasonably matched with the ultrasonic parameters. 4) After the welding is completed, turn off the system, cool it to room temperature in air, wipe it clean, and complete the welding. The invention ensures that the ultrasonic field can effectively control the deflection of the arc, compress the arc, enhance the energy of the arc, and effectively solve the key problem of the refractory side wall of the narrow gap.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com