System and method for treating rare earth or nonferrous smelting high-salt and high-COD wastewater

A non-ferrous and wastewater technology, applied in water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve the problems of inability to use biochemical methods and high treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

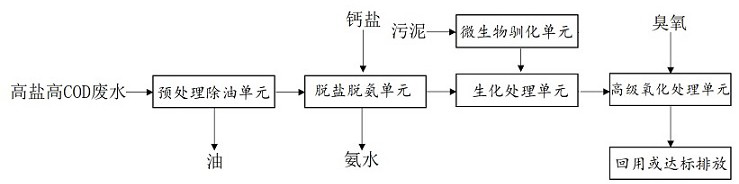

Image

Examples

Embodiment 1

[0029] The water quality of rare earth high-salt wastewater in this embodiment: pH: 3-10, COD: 1000mg / L-5000mg / L,

[0030] Salt content 50-200g / L, BOD: about 400-2000mg / L, SS: 100-1000mg / L.

[0031] Adopt the rare earth high-salt wastewater of the present invention to remove COD steps as follows:

[0032] (1) Pretreatment and degreasing: high-salt wastewater enters the pretreatment and degreasing unit to remove insoluble oil in the wastewater. After passing through the pretreatment and degreasing unit, the obtained wastewater enters step (2) for treatment.

[0033] (2) Desalting and deaminization: the effluent described in step (1) is desalted by adding alkali, stripping and rectifying deaminization, and adding calcium hydroxide and carbonic acid at a ratio of calcium and sulfate radicals of 1~5:1. Calcium salt compounded with calcium, calcium chloride, calcium oxide and sodium hydroxide, stirred and reacted for 10-30 minutes, precipitated and filtered, the salt content is 10...

Embodiment 2

[0037] The water quality of colored high-salt wastewater in this implementation: pH: 6-9, COD: 1000mg / L-3000mg / L,

[0038] Salt content 50-100g / L, BOD: about 400-1200mg / L, SS: 100-1000mg / L.

[0039] Adopt colored high-salt wastewater of the present invention to remove COD step as follows:

[0040] (1) Pretreatment and degreasing: high-salt wastewater enters the pretreatment and degreasing unit to remove insoluble oil in the wastewater. After passing through the pretreatment and degreasing unit, the obtained wastewater enters step (2) for treatment.

[0041] (2) Desalting and deaminization: the effluent described in step (1) is desalted by adding alkali stripping and rectifying deaminization, adding calcium hydroxide and carbonic acid at a ratio of calcium and sulfate radicals of 1 to 4:1 Calcium salt compounded with calcium, calcium chloride, calcium oxide and sodium hydroxide, stirred and reacted for 10-30 minutes, precipitated and filtered, the salt content is 10-20g / L, and t...

Embodiment 3

[0045] The water quality of rare earth high-salt wastewater in this embodiment: pH: 5-10, COD: 1000mg / L-2000mg / L,

[0046] Salt content 50-80g / L, BOD: about 400-800mg / L, SS: 100-1000mg / L.

[0047] Adopt the rare earth high-salt wastewater of the present invention to remove COD steps as follows:

[0048] (1) Pretreatment and degreasing: high-salt wastewater enters the pretreatment and degreasing unit to remove insoluble oil in the wastewater. After passing through the pretreatment and degreasing unit, the obtained wastewater enters step (2) for treatment.

[0049] (2) Desalting and deaminization: the effluent described in step (1) is desalted by adding alkali stripping and rectifying deaminization, adding calcium hydroxide and carbonic acid at a ratio of calcium and sulfate radicals of 1~3:1 Calcium salt compounded with calcium, calcium chloride, calcium oxide and sodium hydroxide, stirred and reacted for 10-30 minutes, precipitated and filtered, the salt content is 10-20g / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com