A kind of water purifying agent for industrial waste water and preparation method thereof

A technology of industrial wastewater and water purifiers, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of low adsorption performance, reduce COD, improve sterilization performance, and improve adsorption and flocculation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

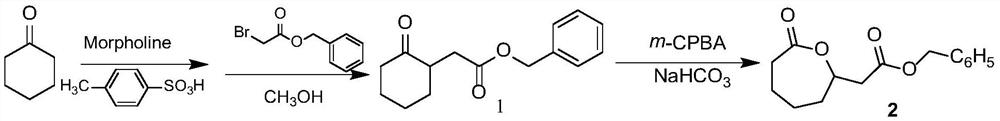

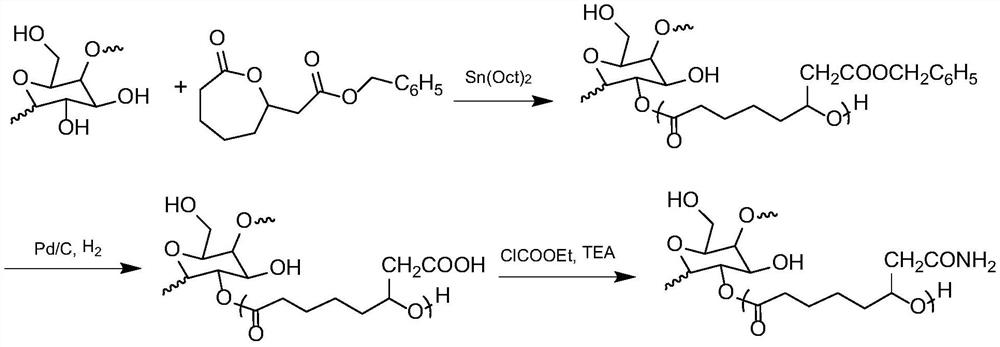

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of water purifying agent for industrial wastewater, obtained by the following steps:

[0024] Step 1: Add 10 parts of water to the mixer, set the temperature to 35°C, adjust the rotation speed to 80-100r / min, add 13 parts of attapulgite and 6 parts of polysilicate, mix and stir for 10 minutes;

[0025] Step 2: Add 38 parts of modified starch and 7 parts of carboxylated nanocellulose, at the same time add 12 parts of water, mix and stir for 20min;

[0026] Step 3: adding 5 parts of biological sterilizing agent and 12 parts of water, mixing and stirring for 30 minutes, to prepare the water purifying agent.

[0027] Wherein, the synthetic process of described carboxylated nanocellulose is as follows:

[0028] Take 2g of microcrystalline cellulose and 50ml of 2.0mol / L ammonium persulfate solution, mix well, stir ultrasonically at 70 °C for 2h, then add 100ml of water to stop the reaction, and repeat centrifugation after the reaction to obtain milky whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com