Method and system for treating saline wastewater

A technology for saline wastewater and wastewater treatment, applied in water treatment parameter control, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as difficult treatment of high-salt sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

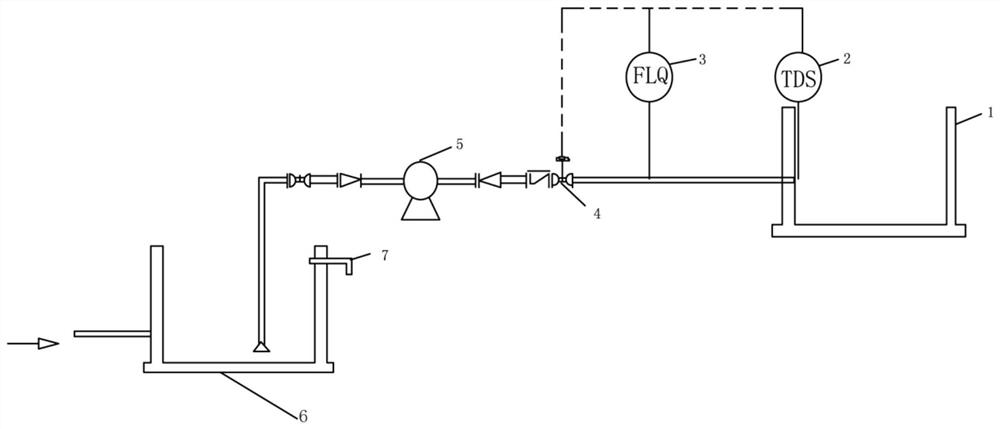

Image

Examples

Embodiment 1

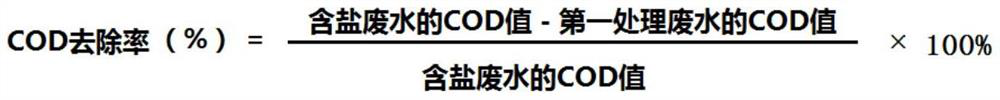

[0071] COD and COD removal rate were selected as water quality parameters, and optimal TDS was set for the biochemical system containing halophagic bacteria. Specific steps are as follows:

[0072] (1) Pass industrial saline wastewater into activated sludge containing halophilic bacteria, use activated sludge to desalinize the saline wastewater to obtain the first treated wastewater, and gradually increase the salt content in the process of desalination pretreatment The flow rate of waste water, measure the TDS value of saline waste water at different flow rates, and measure the COD value of saline waste water at different flow rates;

[0073] (2) measure the COD of the first treatment waste water that desalination pretreatment obtains under different flows, to obtain the COD value of the first treatment waste water, by utilizing the COD value of the first treatment waste water and the saline waste water measured in step (1) Calculate the COD removal rate of the first treated...

Embodiment 2

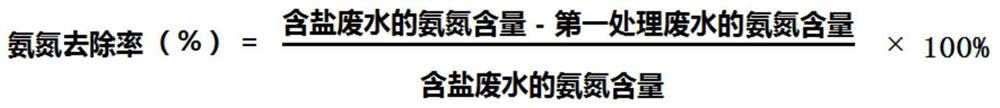

[0079] The ammonia nitrogen content and ammonia nitrogen removal rate were selected as water quality parameters, and the optimal TDS was set for the biochemical system containing halophagic bacteria. Specific steps are as follows:

[0080] (1) Pass industrial saline wastewater into activated sludge containing halophilic bacteria, use activated sludge to desalinize the saline wastewater to obtain the first treated wastewater, and gradually increase the salt content in the process of desalination pretreatment The flow rate of waste water, measure the TDS value of saline waste water at different flow rates, and measure the ammonia nitrogen content of saline waste water at different flow rates;

[0081] (2) measure the ammonia nitrogen content of the first treatment waste water that desalination pretreatment obtains under different flows, to obtain the ammonia nitrogen content value of the first treatment waste water, by utilizing the ammonia nitrogen content value of the first tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com