Colorless aluminate-niobate glass and preparation method and application thereof

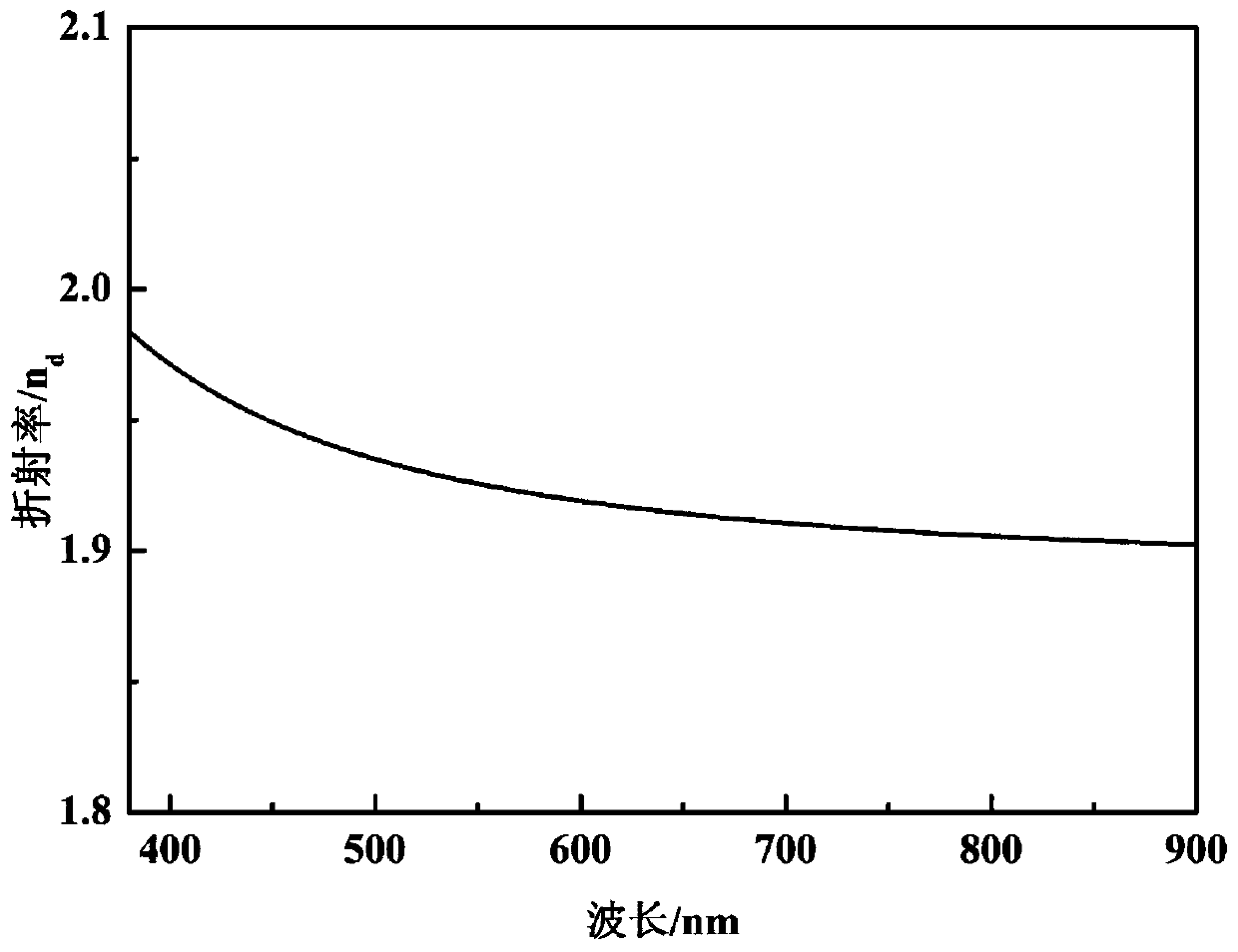

A technology of aluminum niobate and glass, which is applied in the field of aluminum niobate glass and its preparation, can solve problems such as uniformity, achieve the effects of improving forming ability, high refractive index, and solving the problem of high melting point oxide refractory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0055] A colorless aluminum niobate glass and a preparation method thereof, specifically comprising the following steps:

[0056] (1) Prepare the raw materials in the molar ratio of Table 1, and mix the raw materials in a mortar;

[0057] (2) The powder after mixing is pressed into sheet material under the pressure of 10MPa;

[0058] (3) The flake material is calcined at 1100°C for 6 hours, and divided into block raw materials with a mass of about 60mg / block;

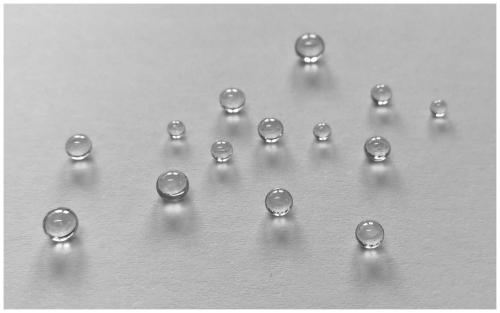

[0059] (4) Place the block in the nozzle of the pneumatic suspension furnace, and pass high-purity O 2 To stabilize the block suspended in the air, use three beams of CO 2 Laser heating to 2400°C to heat the block to a molten state, and then cooling at a cooling rate of 250°C / min to obtain glass pellets with a diameter of 3mm;

[0060] (5) Put the glass ball into a muffle furnace for annealing treatment, the annealing temperature is 800°C, and the annealing time is 2h, to obtain spherical colorless aluminum niobate g...

Embodiment 10-18

[0062] A colorless aluminum niobate glass and a preparation method thereof, specifically comprising the following steps:

[0063] (1) Prepare the raw materials in the molar ratio of Table 2, and mix the raw materials in a mortar;

[0064] (2) The powder after mixing is pressed into sheet material under the pressure of 12MPa;

[0065](3) The flake material is calcined at 1100°C for 3 hours, and divided into block raw materials with a mass of about 60mg / block;

[0066] (4) Place the block in the nozzle of the pneumatic suspension furnace, and pass high-purity O 2 To stabilize the block suspended in the air, use three beams of CO 2 Laser heating to 2400°C to heat the block to a molten state, and then cooling at a cooling rate of 250°C / min to obtain glass pellets with a diameter of 3mm;

[0067] (5) Put the glass ball into a muffle furnace for annealing treatment, the annealing temperature is 800°C, and the annealing time is 2h.

[0068] Table 1

[0069]

[0070] Table 2 ...

Embodiment 19-27

[0073] A colorless aluminum niobate glass and a preparation method thereof, specifically comprising the following steps:

[0074] (1) Prepare the raw materials in the molar ratio of Table 3, and mix the raw materials in a mortar;

[0075] (2) The powder after mixing is pressed into sheet material under the pressure of 12MPa;

[0076] (3) The flake material is calcined at 1100°C for 3 hours, and divided into block raw materials with a mass of about 90mg / block;

[0077] (4) Place the block in the nozzle of the pneumatic suspension furnace, and pass high-purity O 2 To stabilize the block suspended in the air, use three beams of CO 2 Laser heating to 2500°C to heat the block to a molten state, and then cooling at a cooling rate of 250°C / min to obtain glass pellets with a diameter of 3.5mm;

[0078] (5) Put the glass ball into a muffle furnace for annealing treatment, the annealing temperature is 810°C, and the annealing time is 3h.

[0079] table 3

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com