High-modulus glass fiber with excellent alkali resistance and preparation method ofhigh-modulus glass fiber

A technology of glass fiber and alkali resistance, which is applied in the field of high modulus glass fiber and its manufacturing, and can solve the problems of insufficient alkali resistance of glass fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

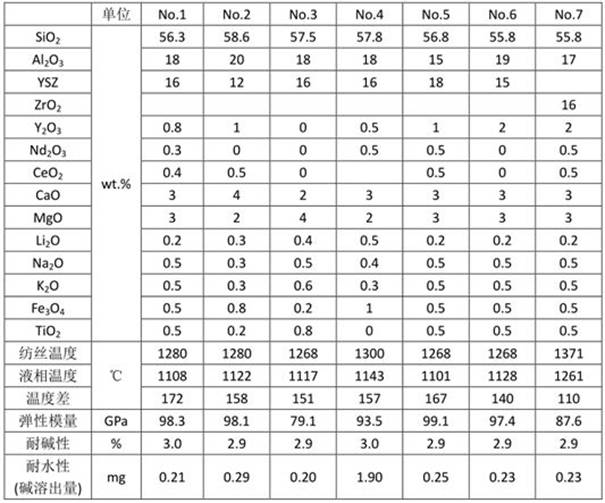

[0037] Table 1 shows the specific components and corresponding properties of Examples 1-7 listed in the present invention. Wherein, No.1-No.3, No.5-No.6 are preferred embodiments of the present invention, and No.4 and No.7 are comparative examples for comparison. In the performance test, the liquidus temperature, elastic modulus, alkali resistance and water resistance of the glass fiber composition and the glass fiber prepared by it were mainly tested, as well as the set suitable spinning temperature and the corresponding spinning temperature The temperature difference from the liquidus temperature.

[0038] Table 1

[0039]

[0040] It can be seen from Table 1 that in the present invention, YSZ is used to replace zirconia, which can effectively reduce the liquidus temperature of the glass fiber composition, thereby reducing the required suitable spinning temperature. At the same time, the substitution between YSZ and zirconia did not affect the alkali resistance of glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com