High-rubber asphalt master batch and low-temperature environmental-friendly production process thereof

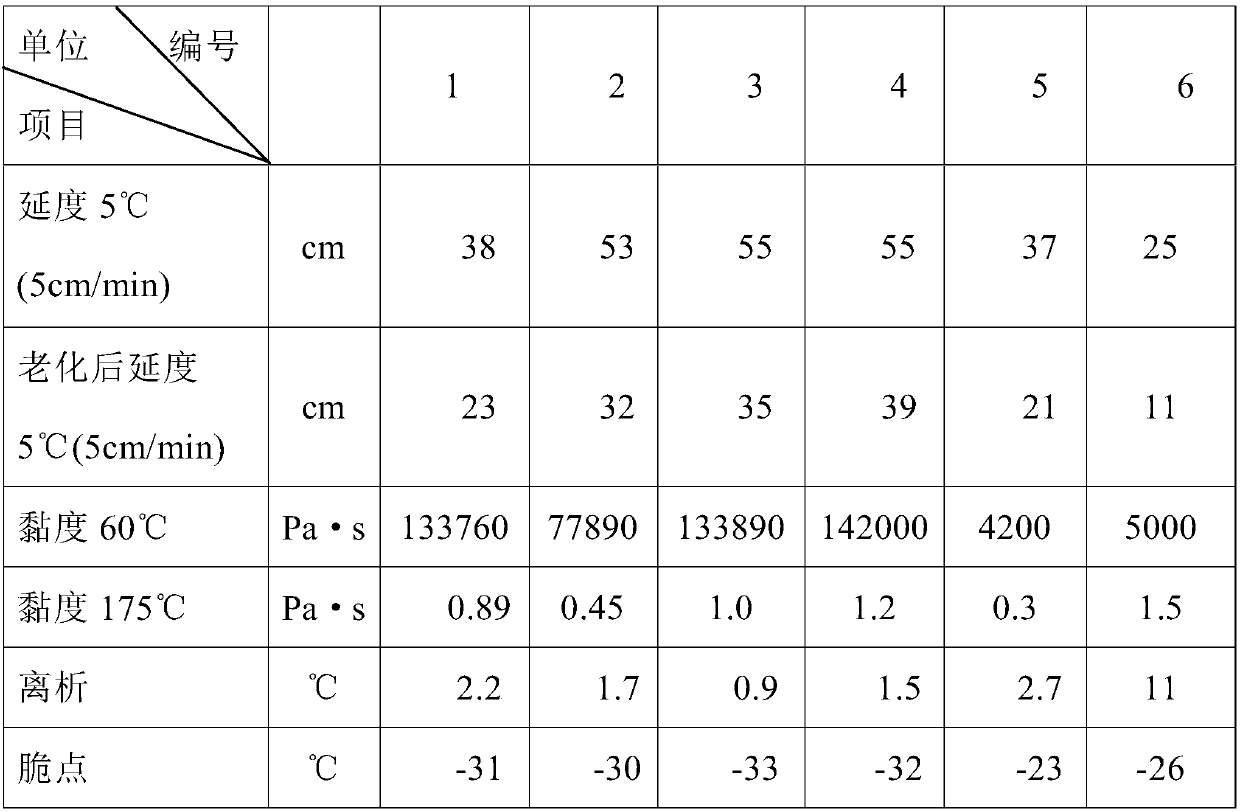

A production process and asphalt technology, applied in the field of high-rubber asphalt masterbatch and its low-temperature environmental protection production process, can solve the problems of high temperature viscosity of modified asphalt, substandard environmental emission indicators, easy settling of asphalt, etc., and achieve good aging resistance performance. , shorten the production cycle, enhance the effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Mix 50 parts by mass of 30-mesh 900in tire vulcanized rubber powder and 10 parts by mass of furfural oil in a pre-development tank, and degrade and develop for 5 hours.

[0046] (2) Add 40 parts by mass of Ssangyong 70#A grade matrix asphalt purchased from S-Oil to the pre-development tank pump, and transport the pre-development tank material to the reactor through the screw pump, and pass the model SYJZM02-30 / 0.2 type The homogeneous colloid mill is used for shear blending for 2 hours, and then the mixture is sent to the decay tank for 3-5 days, and the target viscosity at 135°C is 1-2 Pa·s to obtain a high-glue asphalt masterbatch.

[0047] (3) 8 parts by mass of high-glue asphalt masterbatch and 9 parts by mass of star-shaped SBS (mass average molecular weight: 120,000) purchased from Yueyang Petrochemical were blended with 80 parts by mass of road petroleum asphalt through a colloid mill, and the temperature was kept at 160°C Until the SBS is completely swollen....

Embodiment 2

[0050] (1) Mix 10 parts by mass of 100-mesh 1000in tire vulcanized rubber powder and 10 parts by mass of aromatic oil in a pre-development tank, and degrade and develop for 3 hours.

[0051] (2) Add 80 parts by mass of Ssangyong 70#A grade matrix asphalt purchased from S-Oil to the pre-development tank pump, and transport the pre-development tank material to the reactor through the screw pump, and pass the model SYJZM02-30 / 0.2 type The homogeneous colloid mill is used for shear blending for 2 hours, and then the mixture is sent to the decay tank for 3-5 days, and the target viscosity at 135°C is 1-2 Pa·s to obtain a high-glue asphalt masterbatch.

[0052] (3) 32 parts by mass of high-glue asphalt masterbatch and 1 part by mass of star-shaped SBS (mass average molecular weight: 300,000) purchased from Yueyang Petrochemical were blended with 66.8 parts by mass of road petroleum asphalt through a colloid mill, and the temperature was kept at 190°C Until the SBS is completely swol...

Embodiment 3

[0055] (1) Mix 25 parts by mass of 80-mesh 1100in tire vulcanized rubber powder and 5 parts by mass of shale oil in a pre-development tank, and degrade and develop for 3 hours.

[0056] (2) Add 70 parts by mass of Ssangyong 70#A grade matrix asphalt purchased from S-Oil to the pre-development tank pump, and transport the pre-development tank material to the reactor through the screw pump, and pass the model SYJZM02-30 / 0.2 type The homogeneous colloid mill is sheared and blended for 1 hour, and then the mixture is sent to the decay tank for 3-5 days, and the target viscosity at 135°C is 1-2 Pa·s to obtain a high-glue asphalt masterbatch.

[0057] (3) 15 parts by mass of high-adhesive asphalt masterbatch and 5 parts by mass of star-shaped SBS (mass average molecular weight: 300,000) purchased from Yueyang Petrochemical were blended with 78.5 parts by mass of road petroleum asphalt through a colloid mill, and the temperature was kept at 190°C Until the SBS is completely swollen. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com