Flocculating agent for sand washing and mineral separation and preparation method thereof

A technology of flocculant and initiator, which is applied in the field of flocculant for sand washing and beneficiation and its preparation, can solve the problems of limiting the use of polyacrylamide, high cost, high price of polyacrylamide, etc., and achieves fast settling speed and reduced Manufacturing costs, the effect of realizing environmentally friendly utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

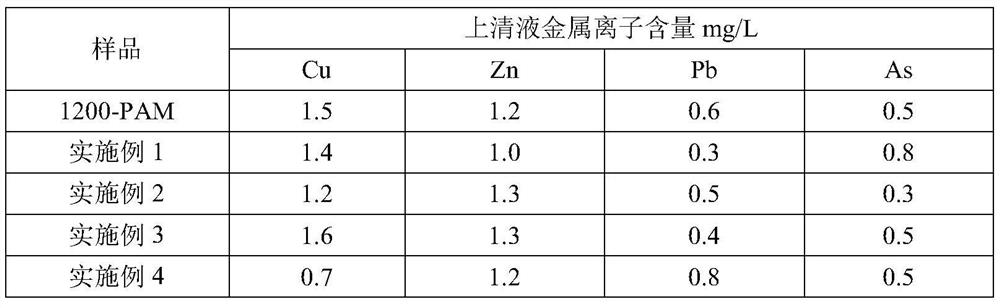

Examples

preparation example Construction

[0030] A preparation method of flocculant for sand washing ore dressing, characterized in that it comprises the following steps:

[0031] S1. At normal temperature, put the waste acid into the stirred reactor, put in the basic salt and modifier in turn, and stir for 0.5~1h; after the reaction, continue to put in the catalyst, then raise the temperature to 80~110℃, and reflux for 12~ After 24h, it was naturally cooled to room temperature.

[0032] S2. Add liquid caustic soda to the S1 solution to adjust the pH to 7-8, then lower the temperature to ≤6°C, catalyze nitrogen and deoxygenate for 30 minutes, then continue to add chain transfer agent and azo initiator in sequence, and stir for 5 to 10 minutes before reacting Add reducing agent and persulfate initiator in sequence, continue to react for 5 to 10 minutes, stop stirring and let stand for 2 to 10 hours to obtain colloid flocculant, then granulate the colloid, and put it in a vacuum oven at 75 to 85°C for 6 After ~8 hours, i...

Embodiment 2

[0034] At normal temperature, put 835 parts of waste acid into the stirred reactor, then put in 48 parts of sodium carbonate and 62 parts of ammonium hydroxide, and stir for 0.5h; The temperature was raised to 110°C, and the reaction was refluxed for 12 hours, and then naturally cooled to room temperature. Then add 15 parts of liquid caustic soda to the above solution to adjust the pH to 7.6, then lower the temperature to ≤6°C, catalyze nitrogen and deoxygenate for 30 minutes, then continue to add 0.3 parts of sodium formate and 0.15 parts of azobisisobutylamidine hydrochloride in sequence, and stir for 5 Add 0.28 parts of sodium bisulfite and 0.05 parts of sodium persulfate in turn after 10 minutes, continue to react for 5 minutes, stop stirring and let stand for 6 hours to obtain colloid flocculant, then granulate the colloid, and dry in a vacuum oven at 75°C for 8 hours After crushing, the flocculant for sand washing and beneficiation can be obtained.

Embodiment 3

[0036] At room temperature, put 886 parts of waste acid into a stirred reactor, then put in 60 parts of sodium bicarbonate and 75 parts of hydroxyammonium chloride, and stir for 1 hour; after the reaction, continue to put in 0.007 parts of indium fluoride trihydrate and 0.003 parts of four Hydrate cobalt acetate, then heat up to 80°C, reflux for 24 hours, then cool down to room temperature naturally. Then add 28 parts of liquid caustic soda to the above solution to adjust the pH to 7.4, then lower the temperature to ≤6°C, and then continue to add 0.3 parts of isopropanol and 0.008 parts of azobisisopropylimidazoline hydrochloride successively after nitrogen and oxygen removal for 30 minutes. Stir the reaction for 5 minutes, then add 0.015 parts of ferrous sulfate and 0.002 parts of potassium persulfate in turn, continue the reaction for 10 minutes, stop stirring and let it stand for 2 hours to obtain a colloidal flocculant, then granulate the colloid and place it in a vacuum ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com