Method for preparing water glass by utilizing waste lead-containing glass and separating lead-containing compound

A technology for waste lead-containing glass and water glass, applied in the directions of lead sulfide, alkali metal silicate, silicate, etc., can solve problems such as lead waste, achieve recycling, solve the problem of refractory degradation, and cure pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

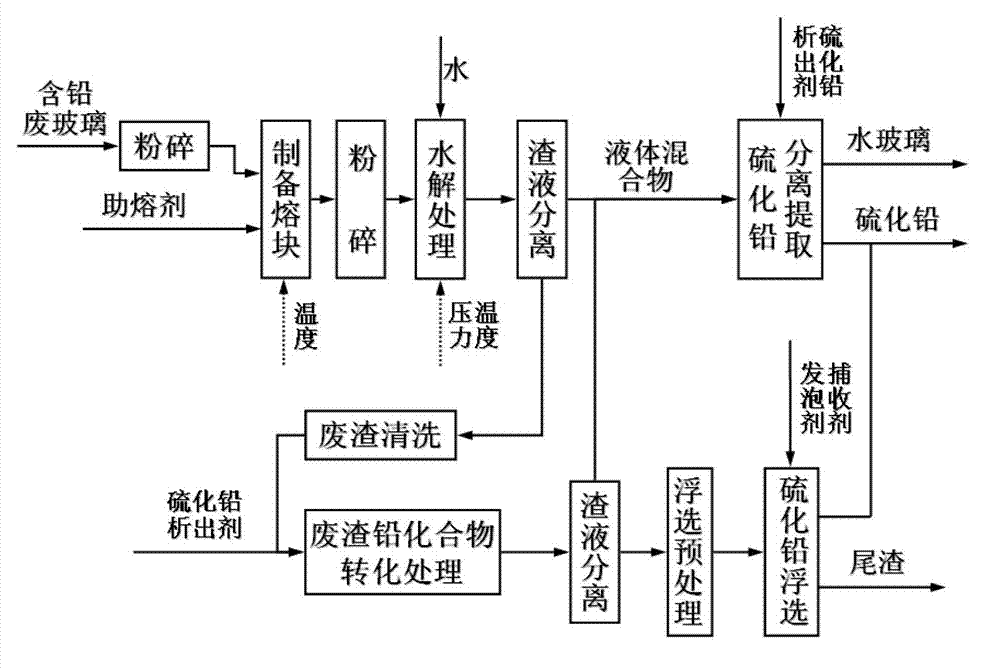

[0020] A method for preparing water glass from waste lead-containing glass and separating lead-containing compounds. First, the lead-containing glass of the waste cathode ray tube is made into water glass frit, then the frit is hydrolyzed, and the hydrolyzate is separated from the hydrolyzate. Obtain the water glass solution, then add additives to convert the lead dissolved in the water glass into lead sulfide, separate and collect the lead sulfide precipitate, obtain lead-free potassium or sodium water glass solution, and further process the dissolved residue to make it The lead-containing compound is converted into lead sulfide, and the lead sulfide in the hydrolysis slag is recovered by the flotation method. The process flow is shown in the attached drawing.

[0021] The method for producing potassium water glass and separating lead-containing compound with waste lead-containing glass, the steps are as follows:

[0022] 1) Preparation of frit: crush the waste CRT lead-conta...

Embodiment 2

[0031] The method for preparing sodium water glass and separating lead-containing compound with waste lead-containing glass, the steps are as follows:

[0032] 1) Preparation of frit: crush waste CRT lead-containing glass, particle size ≤ 50 mm, take 1000 kg of crushed material and add 250 kg of sodium carbonate, mix well and put it in a melting furnace, melt and react at 1100 ° C for 2 hours, the reaction product After cooling, it becomes a frit, and after cooling to normal temperature, the material is pulverized to obtain a frit pulverized material with a particle size of ≦10 mm;

[0033] 2) Hydrolysis reaction: Put the above pulverized materials into a reaction kettle, add 2550 kg of water, and carry out hydrolysis reaction at a temperature of 200°C, a pressure of 1.5MPa, and a stirring speed of 400 rpm, and the reaction time is 0.5 hours , obtain the mixture of liquid phase water glass and residue precipitate;

[0034] 3) Separation and extraction of water glass: After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com