Special fertilizer for primary root zone of sugarcane and preparation process of fertilizer

A preparation process, a technology for special fertilizers, applied in the application, potash fertilizer, inorganic fertilizer and other directions, can solve the problems of increasing the use frequency of chemical fertilizers, increasing production costs, increasing the amount of chemical fertilizers applied, etc., to improve the utilization rate of fertilizers, improve efficiency, The effect of reducing the frequency of fertilizer use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

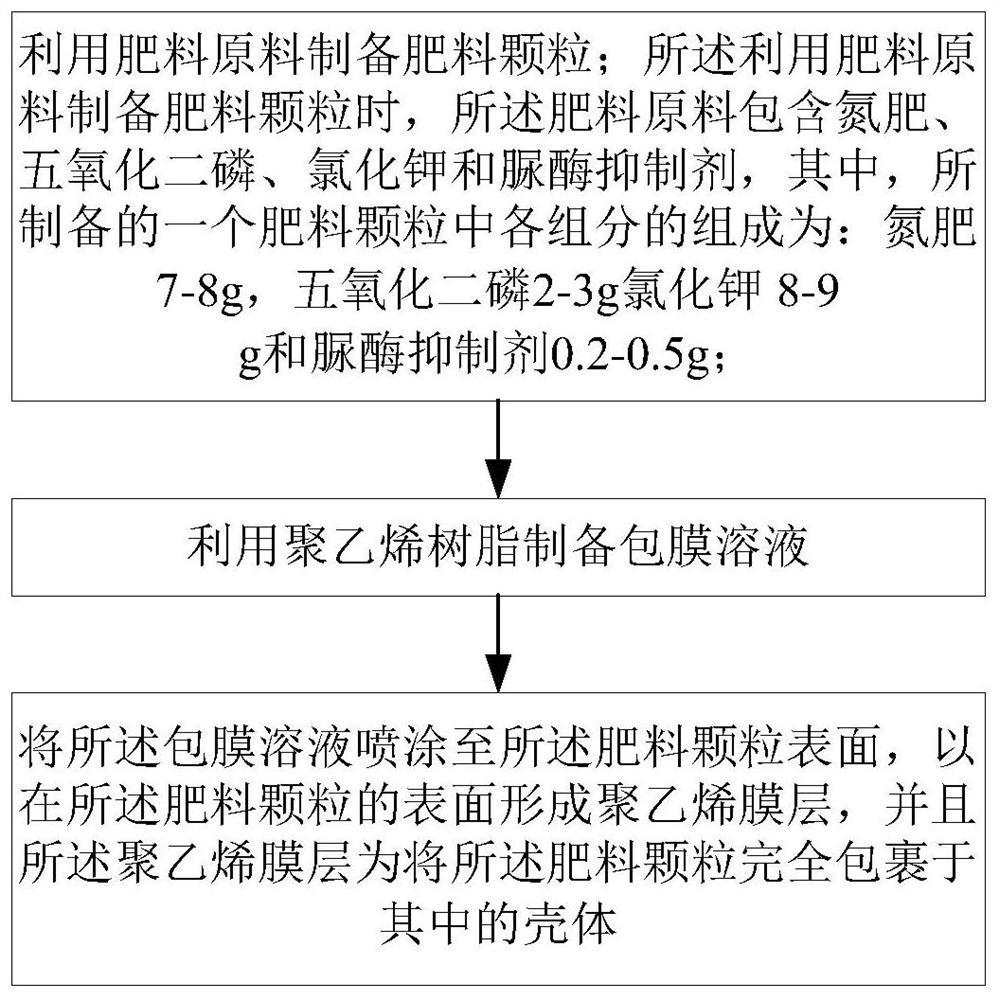

[0041] The fertilizer needed for each sugarcane is as follows: nitrogen 8g per tree, phosphorus pentoxide 2.86g per tree, potassium chloride 8.57g per tree, urease inhibitor 0.2-0.5g per tree. 3,500 sugarcane trees are planted per mu, and the fertilization conditions per mu are as follows: nitrogen 28kg per mu, phosphorus pentoxide 10kg per mu, potassium chloride 30kg per mu.

[0042] According to the fertilizer situation required by each sugarcane, determine the ratio of each component contained in a fertilizer granule: nitrogen 7-8g, phosphorus pentoxide 2-3g, potassium chloride 8-9g, urease inhibitor 0.2 -0.5g. Fertilizer raw materials are prepared into powder, and then granulated by a granulator. Specifically, take each component of the fertilizer raw material, mix the components of the fertilizer raw material, add water and carrageenan, mix and stir to obtain a mixed preparation; put the mixed preparation into a granulator for high-temperature drying, and the drying temp...

Embodiment 2

[0047] The fertilizer needed for each sugarcane is as follows: nitrogen 8g per tree, phosphorus pentoxide 2.86g per tree, potassium chloride 8.57g per tree, urease inhibitor 0.2-0.5g per tree. 3,500 sugarcane trees are planted per mu, and the fertilization conditions per mu are as follows: nitrogen 28kg per mu, phosphorus pentoxide 10kg per mu, potassium chloride 30kg per mu.

[0048] According to the fertilizer situation required by each sugarcane, determine the ratio of each component contained in a fertilizer granule: nitrogen 7-8g, phosphorus pentoxide 2-3g, potassium chloride 8-9g, urease inhibitor 0.2 -0.5g. Fertilizer raw materials are prepared into powder, and then granulated by a granulator. Specifically, take each component of the fertilizer raw material, mix the components of the fertilizer raw material, add water and carrageenan, mix and stir to obtain a mixed preparation; put the mixed preparation into a granulator for high-temperature drying, and the drying temp...

Embodiment 3

[0053] The fertilizer needed for each sugarcane is as follows: nitrogen 8g per tree, phosphorus pentoxide 2.86g per tree, potassium chloride 8.57g per tree, urease inhibitor 0.2-0.5g per tree. 3,500 sugarcane trees are planted per mu, and the fertilization conditions per mu are as follows: nitrogen 28kg per mu, phosphorus pentoxide 10kg per mu, potassium chloride 30kg per mu.

[0054] According to the fertilizer situation required by each sugarcane, determine the ratio of each component contained in a fertilizer granule: nitrogen 7-8g, phosphorus pentoxide 2-3g, potassium chloride 8-9g, urease inhibitor 0.2 -0.5g. Fertilizer raw materials are prepared into powder, and then granulated by a granulator. Specifically, take each component of the fertilizer raw material, mix the components of the fertilizer raw material, add water and carrageenan, mix and stir to obtain a mixed preparation; put the mixed preparation into a granulator for high-temperature drying, and the drying temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com