Preparation method of nanometer silicon-carbon composite negative electrode material for lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of powdering nano-silicon particle materials, long diffusion and migration paths, and poor electrode conductivity, and achieves a small particle size. , Improve the electrochemical activity, the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Accurately weigh 2.8g of polyacrylonitrile (PAN) powder, 14.4g of N,N-dimethylformamide (DMF) in a 50ml small beaker, and place it in an oil bath at 50°C for 3h at constant temperature, After the PAN powder is completely dissolved, ultrasonically disperse for 4 hours to obtain an outer layer precursor emulsion with a concentration of 14%, which is ready for use;

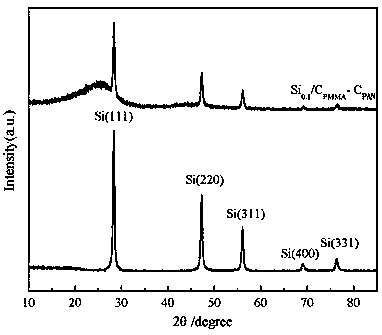

[0035] 2) Accurately weigh 0.4g of nano silicon powder (30nm) and 0.03g of Y-aminopropyltriethoxysilane (KH550) and soak in a 50ml small beaker for 5min, then add 2.6g of polymethyl methacrylate (PMMA) After powder and 17.4g N,N-dimethylformamide (DMF), it was placed in a 35°C oil bath and stirred at a constant temperature for 3 hours. After the PMMA powder was completely dissolved, it was ultrasonicated for 2 hours to obtain a concentration of 13%. Inner layer precursor emulsion, ready for use;

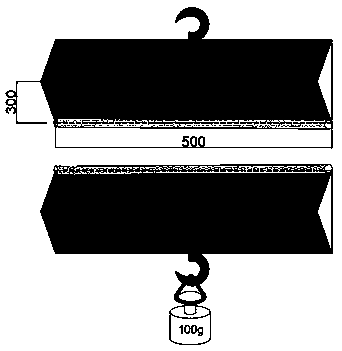

[0036] 3) Select two 20ml syringes to absorb the inner layer emulsion and the outer layer emulsion respectivel...

Embodiment 2

[0041] 1) Accurately weigh 2.8g of polyacrylonitrile (PAN) powder, 14.4g of N,N-dimethylformamide (DMF) in a 50ml small beaker, and place it in an oil bath at 50°C for 3h at constant temperature, After the PAN powder is completely dissolved, ultrasonically disperse for 4 hours to obtain an outer layer precursor emulsion with a concentration of 14%, which is ready for use;

[0042] 2) Accurately weigh 0.4g of nano silicon powder (30nm) and 0.03g of Y-aminopropyltriethoxysilane (KH550) and soak in a 50ml small beaker for 5min, then add 2.8g of polyacrylonitrile (PAN) powder, After 14.4g of N,N-dimethylformamide (DMF), it was placed in a 50°C oil bath and stirred at a constant temperature for 3 hours. After the PAN powder was completely dissolved, it was sonicated for 2 hours to obtain an inner layer precursor with a concentration of 14%. Body emulsion, ready to use;

[0043] 3) Select two 20ml syringes to absorb the inner layer emulsion and the outer layer emulsion respectively...

Embodiment 3

[0048] 1) Accurately weigh 2.8g of polyvinylidene fluoride (PVDF) powder, 14.4g of N,N-dimethylformamide (DMF) in a 50ml small beaker, and place it in a 35°C oil bath and stir for 3h After the PVDF powder is completely dissolved, ultrasonically disperse for 4 hours to obtain an outer layer precursor emulsion with a concentration of 14%, which is ready for use;

[0049] 2) Accurately weigh 0.4g of nano silicon powder (30nm) and 0.03g of Y-aminopropyltriethoxysilane (KH550) and soak in a 50 ml small beaker for 5min, then add 2.6g of polymethyl methacrylate (PMMA) After the powder and 17.4g N,N-dimethylformamide (DMF), it was placed in a 35°C oil bath and stirred at a constant temperature for 3 hours. After the PMMA powder was completely dissolved, it was ultrasonically used for 2 hours to obtain a concentration of 12%. Inner layer precursor emulsion, ready for use;

[0050] 3) Select two 20ml syringes to absorb the inner layer emulsion and the outer layer emulsion respectively,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com