A new type of nano-carbon sphere anode material for lithium-ion batteries

A lithium-ion battery, nano-carbon ball technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of environmental pollution, less lithium-ion de-intercalation sites, and small battery capacity, and achieve guaranteed volumetric energy density and Coulombic efficiency, good reversible capacity and cycling performance, the effect of increased surface oxygen-containing functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

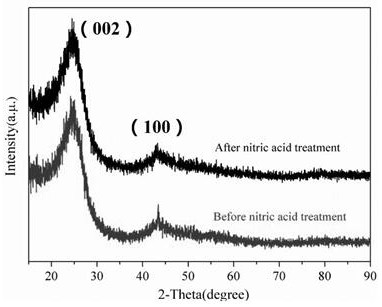

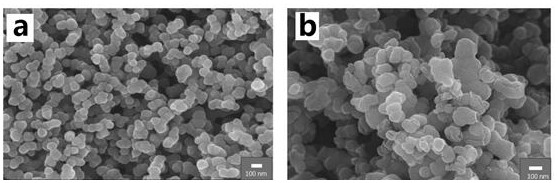

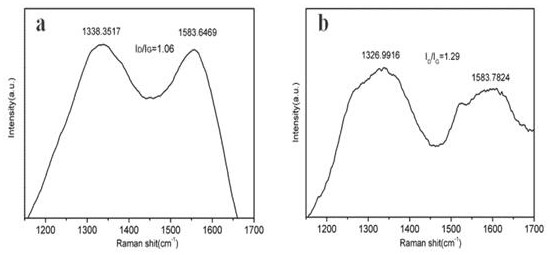

[0028] The tube furnace was heated up to 500°C at a rate of 5°C / min under a nitrogen atmosphere, then acetylene gas was introduced at a flow rate of 100mL / min, and the chemical vapor deposition reaction was carried out for 60 minutes without a catalyst to obtain Nano-carbon spheres, and then place the nano-carbon spheres in a nitric acid solution with a concentration of 60%, and mix and stir at 60°C for 1h. Dry it in a vacuum drying oven for 12 hours, then grind it and pass through a 300-mesh porous sieve to obtain a new nano-carbon sphere negative electrode material for lithium-ion batteries.

Embodiment 2

[0030] The tube furnace was heated up to 500°C at a rate of 5°C / min under a nitrogen atmosphere, then acetylene gas was introduced at a flow rate of 100mL / min, and the chemical vapor deposition reaction was carried out for 60 minutes without a catalyst to obtain Nano-carbon spheres, and then place the nano-carbon spheres in a nitric acid solution with a concentration of 63%, and mix and stir at 60°C for 1h. After the reaction is completed, cool to room temperature, filter and wash until neutral, and then Dry it in a vacuum drying oven for 12 hours, then grind it and pass through a 400-mesh porous sieve to obtain a new nano-carbon sphere negative electrode material for lithium-ion batteries.

Embodiment 3

[0032] The tube furnace was heated up to 450°C at a rate of 7°C / min under a nitrogen atmosphere, and then acetylene gas was introduced at a flow rate of 300mL / min, and the chemical vapor deposition reaction was carried out for 30 minutes without a catalyst to obtain Nano-carbon spheres, and then place the nano-carbon spheres in a nitric acid solution with a concentration of 65%, and mix and stir at 70°C for 1h. Dry it in a vacuum drying oven for 36 hours, then grind it and pass through a 300-mesh porous sieve to obtain a new nano-carbon sphere negative electrode material for lithium-ion batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com