A kind of preparation method and application of nitrogen-doped self-supporting nanofiber membrane

A nanofiber membrane, self-supporting technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problems of poor electrochemical performance and small storage capacity of SIB anode materials, and achieve improved rate performance and improved electrochemical performance. , the effect of excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a nitrogen-doped self-supporting nanofiber membrane, comprising the following steps:

[0032] S1. Accurately weigh 8.7 g of DMF and 1.3 g of PAN, dissolve PAN into DMF and place it in an oil bath at 60 °C and stir at constant temperature for 10 h. After the PAN is completely dissolved, a spinning solution is prepared.

[0033] S2. Use a 20 ml syringe to absorb the spinning solution, fix it on the injection flow rate controller, turn on the electrospinning equipment to adjust the relevant spinning parameters (spinning temperature 45 ℃, humidity 36 %, 22 G needle, voltage 26 Kv, rotation speed 200r / min, flow rate 2 ul / min, the distance between the needle and the receiving plate is 21 cm), and the nanofiber membrane was prepared. The nanofiber membrane was placed in a blast drying oven at 60 °C to remove the solvent for 6 h, and then cut into square sheets of 5 × 9 cm, and the fiber membrane was laminated with a smooth surface graphite sheet.

[003...

Embodiment 2

[0036] A method for preparing a nitrogen-doped self-supporting nanofiber membrane, comprising the following steps:

[0037] S1. Accurately weigh 8.2 g of DMF and 1.8 g of PAN, dissolve PAN into DMF and place it in an oil bath at 50 °C and stir at constant temperature for 10 h. After the PAN is completely dissolved, a spinning solution is prepared.

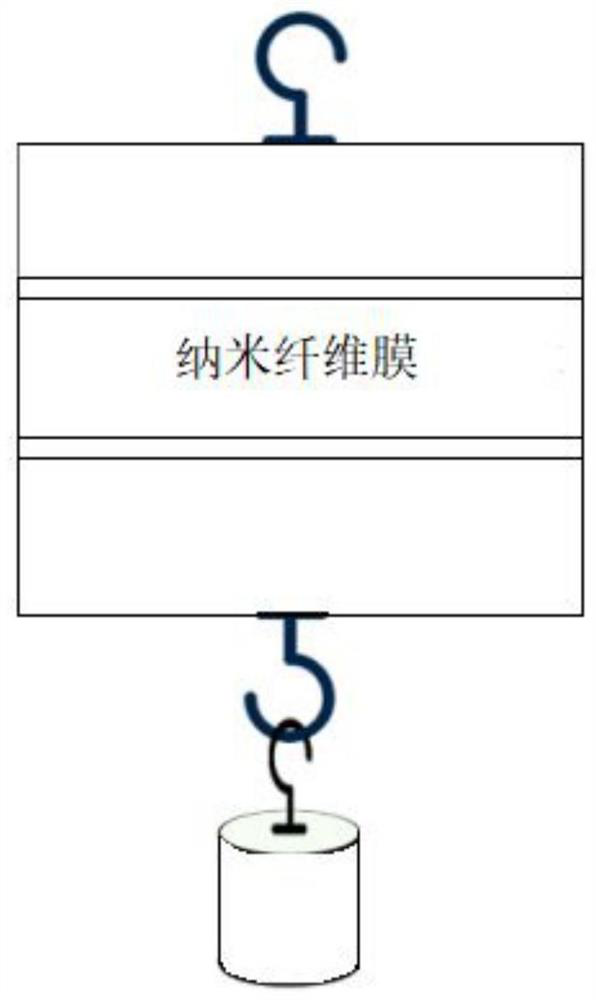

[0038] S2. Use a 20 ml syringe to suck the spinning solution, fix it on the injection flow rate controller, turn on the electrospinning equipment to adjust the relevant spinning parameters (spinning temperature 45 ℃, humidity 36 %, 22 G needle, voltage 26 Kv, rotation speed 200r / min, flow rate 2 ul / min, the distance between the needle and the receiving disc is 21 cm), and the nanofiber membrane was prepared. The nanofiber membrane was placed in a blast drying oven at 60 °C to remove the solvent for 6 h, and then cut into square pieces of 5 × 9 cm. figure 1The shown fixture was loaded with a load of 100 g for 2 h to thermally stret...

Embodiment 3

[0041] A method for preparing a nitrogen-doped self-supporting nanofiber membrane, comprising the following steps:

[0042] S1. Accurately weigh 10 g of DMF and 1.6 g of PAN, dissolve PAN into DMF and place it in an oil bath at 55 °C and stir at constant temperature for 10 h. After the PAN is completely dissolved, a spinning solution is prepared.

[0043] S2. Use a 20 ml syringe to suck the spinning solution, fix it on the injection flow rate controller, turn on the electrospinning equipment to adjust the relevant spinning parameters (spinning temperature 45 ℃, humidity 36 %, 22 G needle, voltage 26 Kv, rotation speed 200r / min, flow rate 2 ul / min, the distance between the needle and the receiving plate is 21 cm), and the nanofiber membrane was prepared. The nanofiber membrane was placed in a blast drying oven at 60 °C for 10 h to remove the solvent, and then cut into square pieces of 5 × 9 cm. figure 1 The jig shown is loaded under a load of 200 g for 2 h to thermally stretch...

PUM

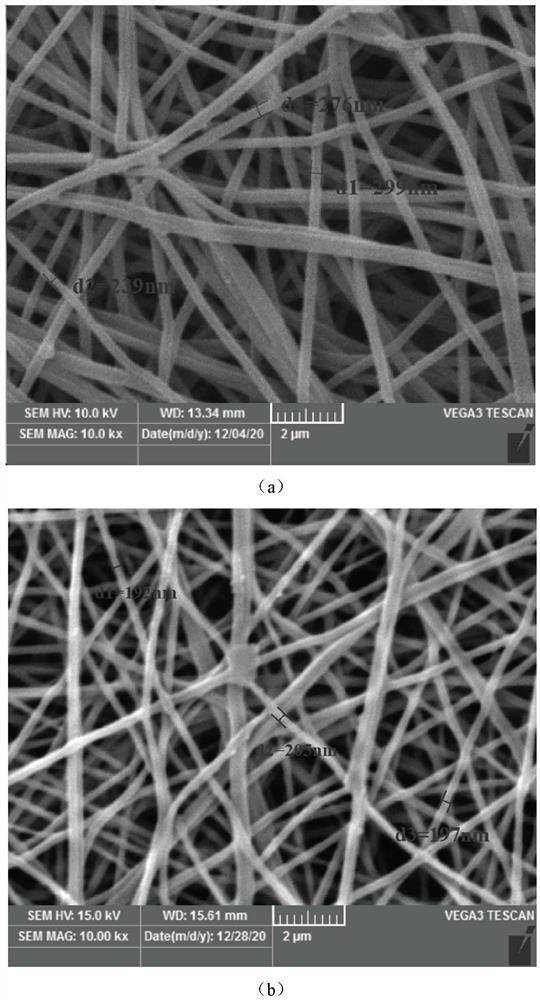

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com