Preparation method and application of iron-cobalt-loaded nitrogen-doped carbon fiber self-supporting membrane catalyst

A nitrogen-doped carbon fiber, self-supporting membrane technology, applied in fuel cell type half-cell and primary cell type half-cell, electrical components, battery electrodes, etc., can solve the problem of poor resistance to methanol poisoning, unstable structure, precious metal High cost and other problems, to achieve the effect of high stability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

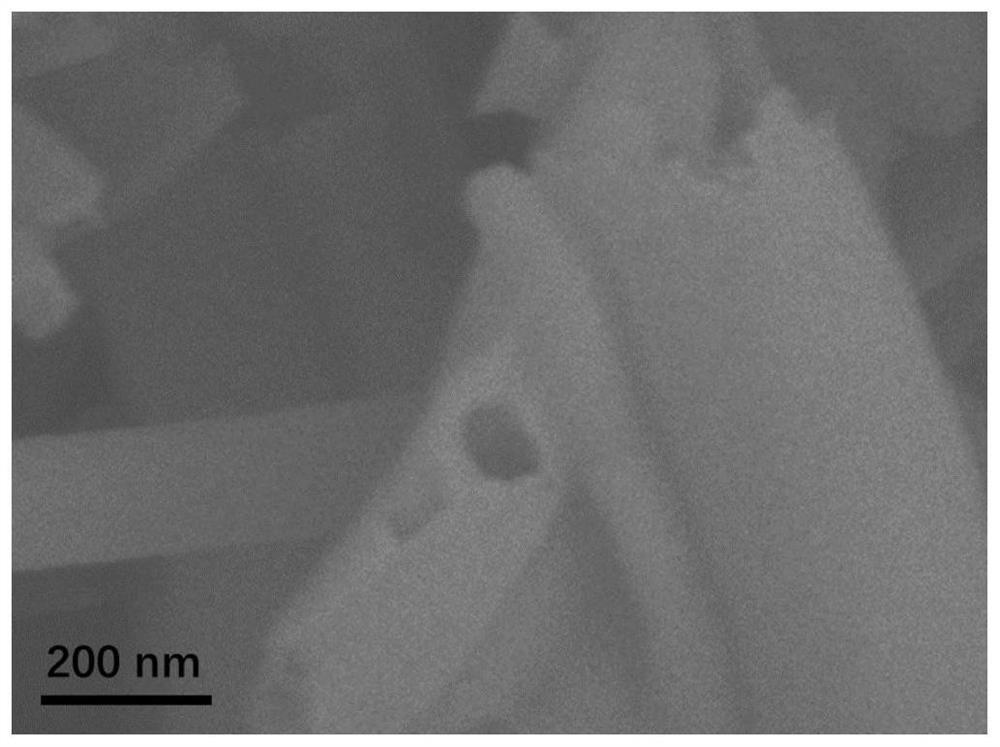

Image

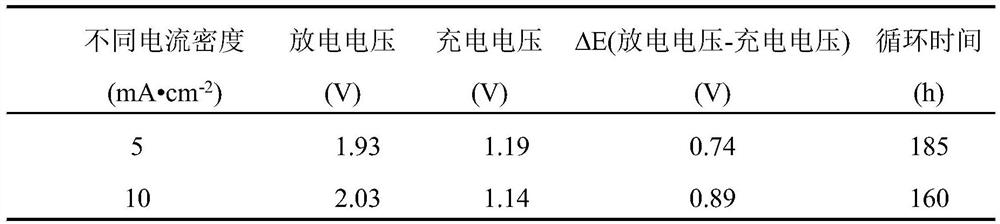

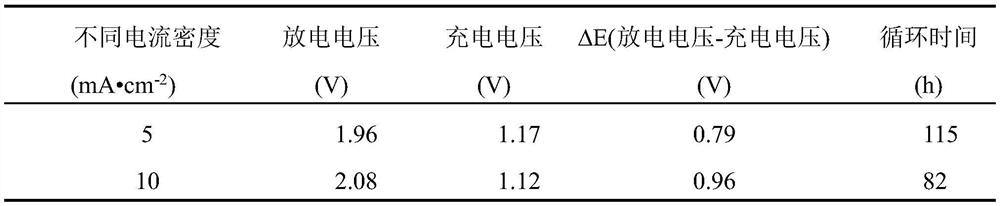

Examples

Embodiment 1

[0027] Embodiment 1: the preparation method of a kind of iron-cobalt loaded nitrogen-doped carbon fiber self-supporting film catalyst in the present embodiment is carried out according to the following steps:

[0028] Step 1. Dissolve 1.2g of polyacrylonitrile in 10mL of DMF, then add 0.0996g of cobalt acetate, and stir until completely dissolved to obtain a shell solution;

[0029] Step 2. Dissolve 2.0 g of polyvinylpyrrolidone in 10 mL of DMF, then add 0.202 g of ferric nitrate, and stir until completely dissolved to obtain a nuclear layer solution;

[0030] Step 3. Inject the shell solution obtained in step 1 and the core layer solution obtained in step 2 into the two solution channels of the coaxial electrospinning device, adjust the coaxial electrospinning parameters for electrospinning, and the conditions for electrospinning For: the positive and negative voltage difference is 20kV; the receiving distance is 15cm; the spray rate of the nuclear layer solution is 0.007mL m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com