Two-dimensional Co/Co9S8-coated NC nanosheet composite material as well as preparation method and application thereof

A technology of composite materials and nanosheets, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low catalyst reserves, high price, and difficulty in simultaneously having both ORR and OER functions, etc. Achieve high catalytic activity, effect on catalytic sites, good oxygen reduction/oxygen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

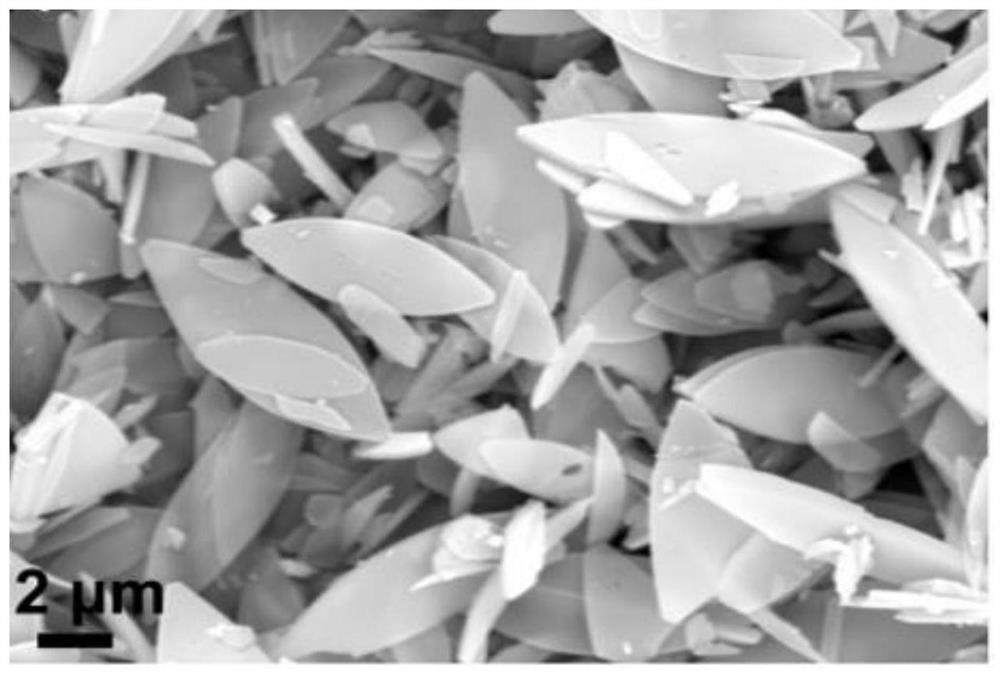

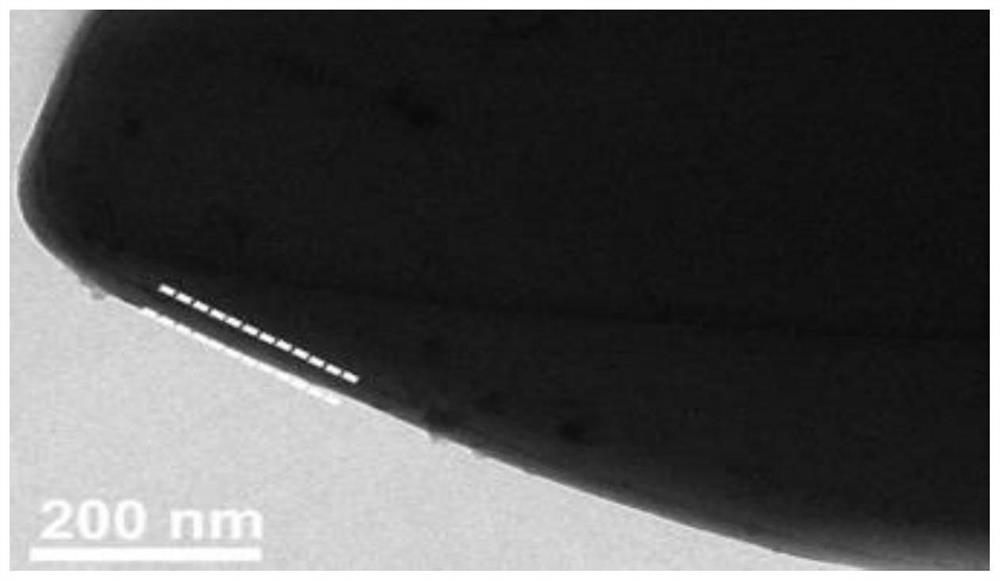

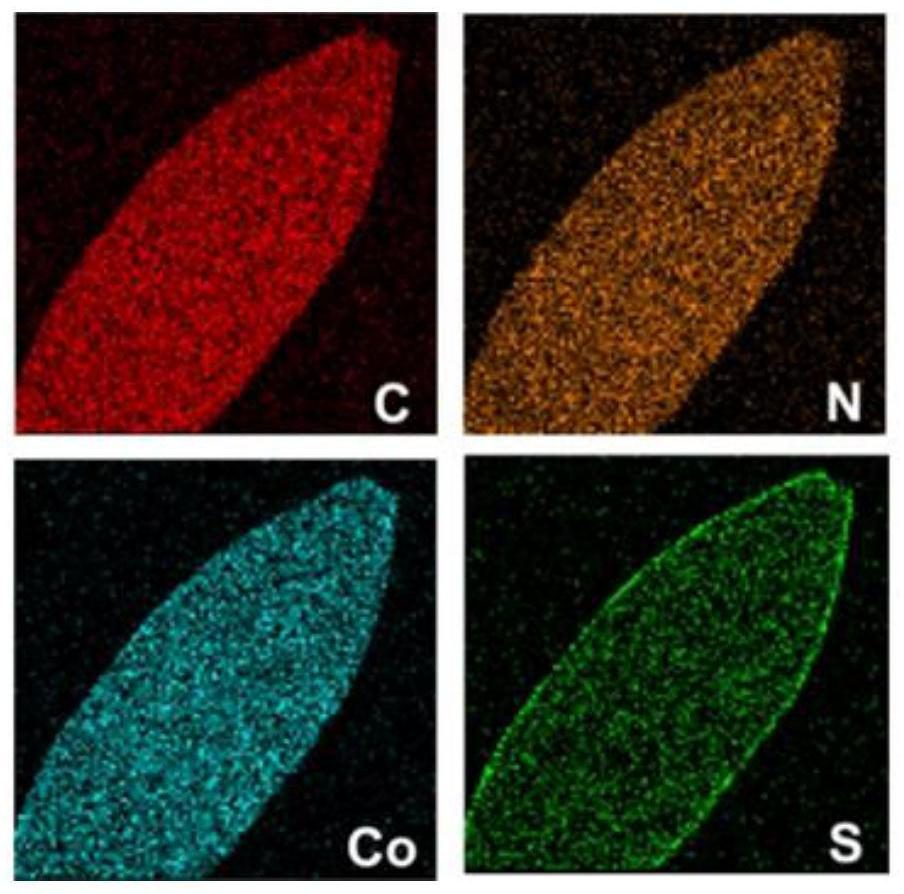

[0027] Two-dimensional Co / Co 9 S 8 The preparation of @NC nanosheet composite material specifically includes the following steps:

[0028] (1) At room temperature, dissolve cobalt nitrate and 2-methylimidazole in 20 mL of water respectively, and after ultrasonication for 30 minutes, the dissolution is complete, and the two solutions are mixed to obtain mixed solution A; in mixed solution A, the concentration of cobalt nitrate is 0.05 mol / L, the concentration of 2-methylimidazole is 0.4mol / L;

[0029] (2) Stir the mixed solution A at room temperature for 3 hours until it is completely dissolved, and dry it by centrifugation to obtain a two-dimensional leaf-shaped imidazolate skeleton;

[0030](3) At room temperature, dissolve 120mg of the two-dimensional leaf-like imidazolate skeleton in 20mL of ethanol, and dissolve 30mg of dithioacetamide in 10mg of ethanol. After ultrasonication for 30 minutes, mix the two, stir them evenly for 1 hour, and centrifuge with ethanol. Wash 3...

Embodiment 2

[0038] Two-dimensional Co / Co 9 S 8 The preparation of @NC nanosheet composite material specifically includes the following steps:

[0039] (1) At room temperature, dissolve cobalt chloride and 2-methylimidazole in 20 mL of water respectively, and after ultrasonication for 30 minutes, the dissolution is complete, and the two solutions are mixed to obtain mixed solution A; in mixed solution A, the concentration of cobalt nitrate is 0.05 mol / L, the concentration of 2-methylimidazole is 0.25mol / L;

[0040] (2) Stir the mixed solution A at room temperature for 3 hours until it is completely dissolved, and dry it by centrifugation to obtain a two-dimensional leaf-shaped imidazolate skeleton;

[0041] (3) At room temperature, dissolve 120mg of the two-dimensional leaf-like imidazolate skeleton in 20mL of ethanol, and dissolve 30mg of dithioacetamide in 10mg of ethanol. After ultrasonication for 30 minutes, mix the two, stir them evenly for 1 hour, and centrifuge with ethanol. Wash...

Embodiment 3

[0045] Two-dimensional Co / Co 9 S 8 The preparation of @NC nanosheet composite material specifically includes the following steps:

[0046] (1) At room temperature, dissolve cobalt nitrate and 2-methylimidazole in 20 mL of water respectively, and after ultrasonication for 30 minutes, the dissolution is complete, and the two solutions are mixed to obtain mixed solution A; in mixed solution A, the concentration of cobalt nitrate is 0.05 mol / L, the concentration of 2-methylimidazole is 0.5mol / L;

[0047] (2) Stir the mixed solution A at room temperature for 3 hours until it is completely dissolved, and dry it by centrifugation to obtain a two-dimensional leaf-shaped imidazolate skeleton;

[0048] (3) At room temperature, dissolve 120mg of the two-dimensional leaf-like imidazolate skeleton in 20mL of ethanol, and dissolve 30mg of dithioacetamide in 10mg of ethanol. After ultrasonication for 30 minutes, mix the two, stir them evenly for 1 hour, and centrifuge with ethanol. Wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com