Preparation method and application of Ce-Co-S-P nanocrystals

A ce-co-s-p, nanocrystalline technology, applied in the field of nanocrystalline, to achieve the effect of low reaction temperature, simple process and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] At room temperature, weigh 203.5 mg (0.375 mmol) of cerium ammonium nitrate and 178.2 mg (0.7 mmol) of cobalt acetylacetonate, and add all the raw materials into a dry three-necked round-bottomed flask with a capacity of 250 mL, and then use a rubber-tip dropper Measure 1.5mL of oleic acid, 8mL of n-dodecanethiol and 5mL of tri-n-octylphosphine into a three-necked round-bottomed flask, and mix well to obtain a solution.

[0027] Transfer the three-neck round-bottom flask to a sand bath, raise the temperature at a rate of 7°C / min to 320°C under programmed temperature control and keep it warm for 30 minutes. Disperse with n-heptane and ethanol, and centrifuge to separate the solid. The product obtained after washing the solid was Ce-Co-S-P nanocrystal, which was vacuum-dried at 60° C. for analysis and characterization.

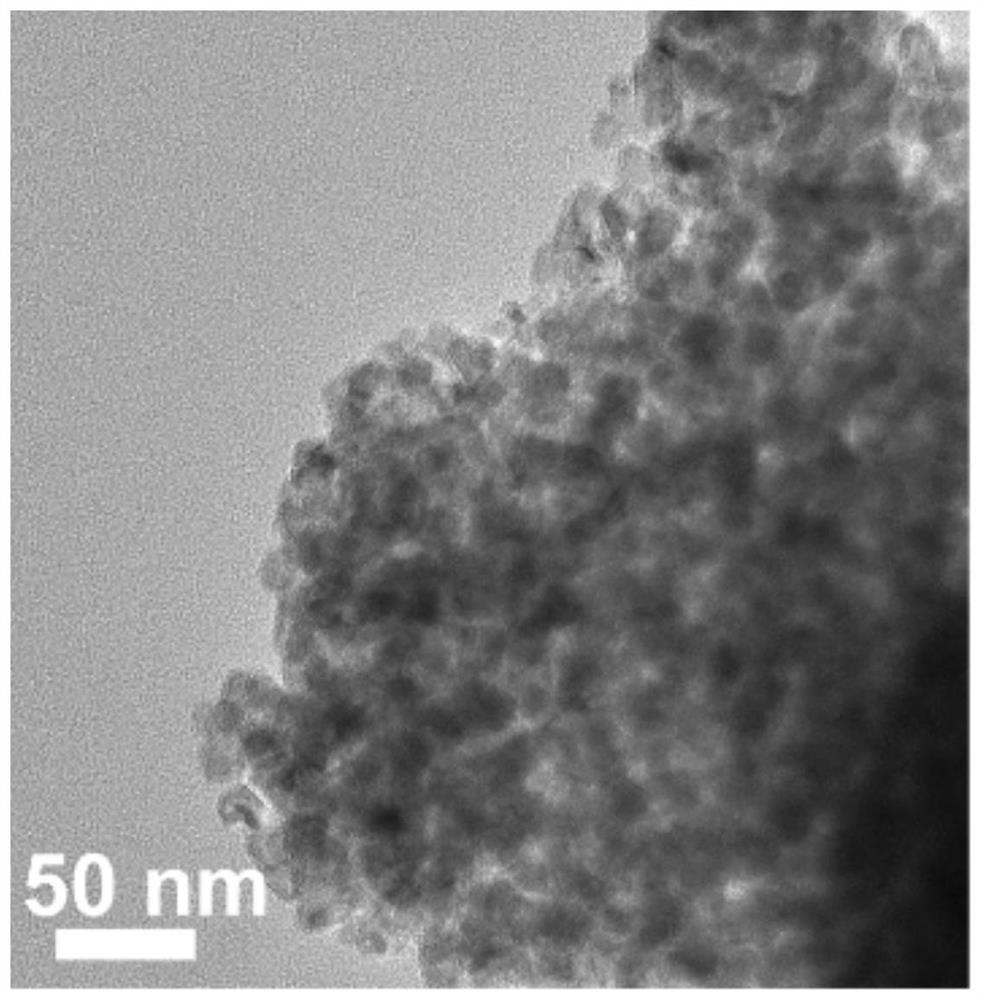

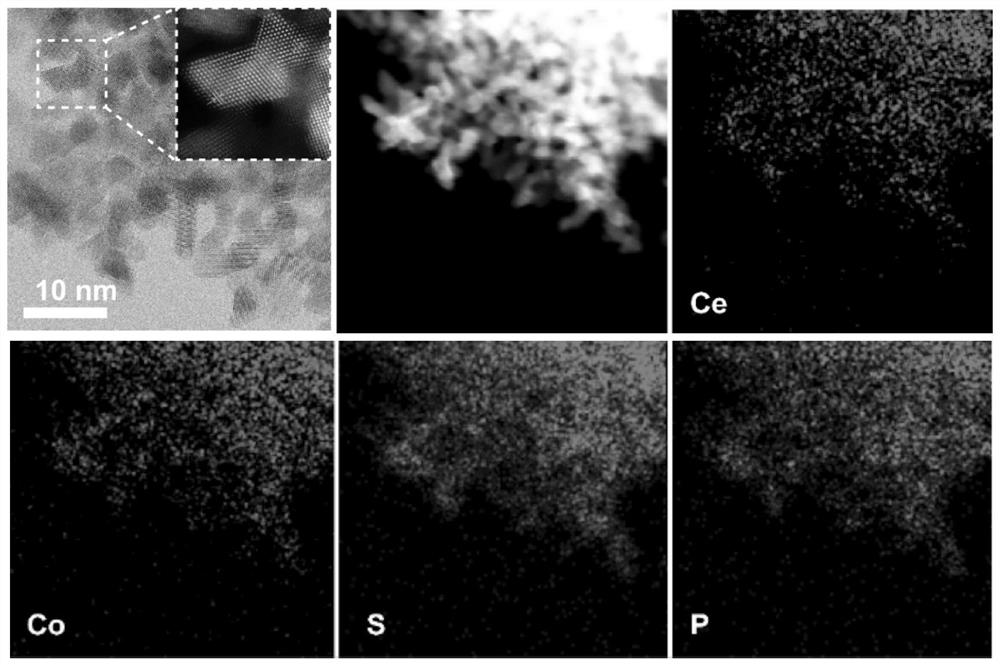

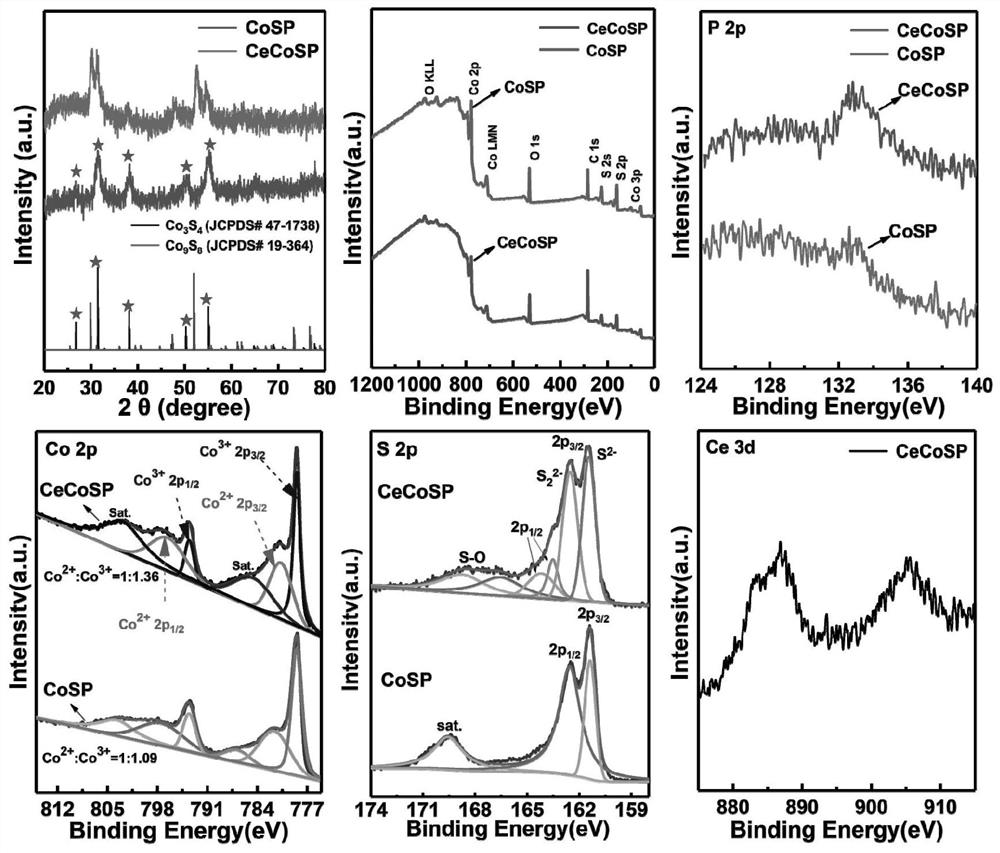

[0028] Using XRD, XPS, Mapping, TEM and HRTEM, EPR test to analyze the product respectively, the results are as follows Figure 1 to Figure 4 shown. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com