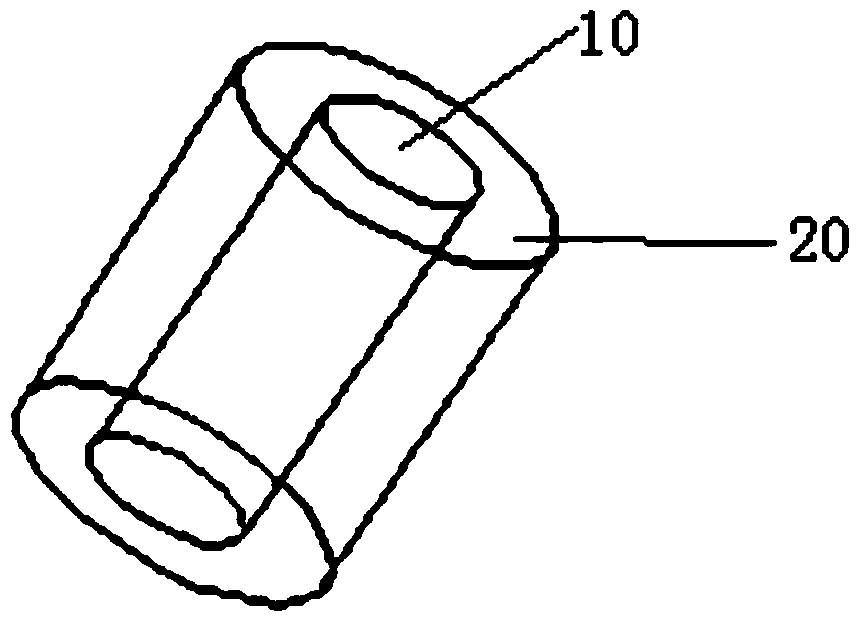

Chitosan-nanofiber hemostatic material and preparation method thereof

A technology of chitosan nano and hemostatic materials, applied in the direction of fiber processing, fiber chemical characteristics, conjugated synthetic polymer artificial filaments, etc., can solve the problems of poor solubility, poor hydrophilicity, and affect the hemostatic effect, and achieve high efficiency , good fibrosis, simple and quick preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

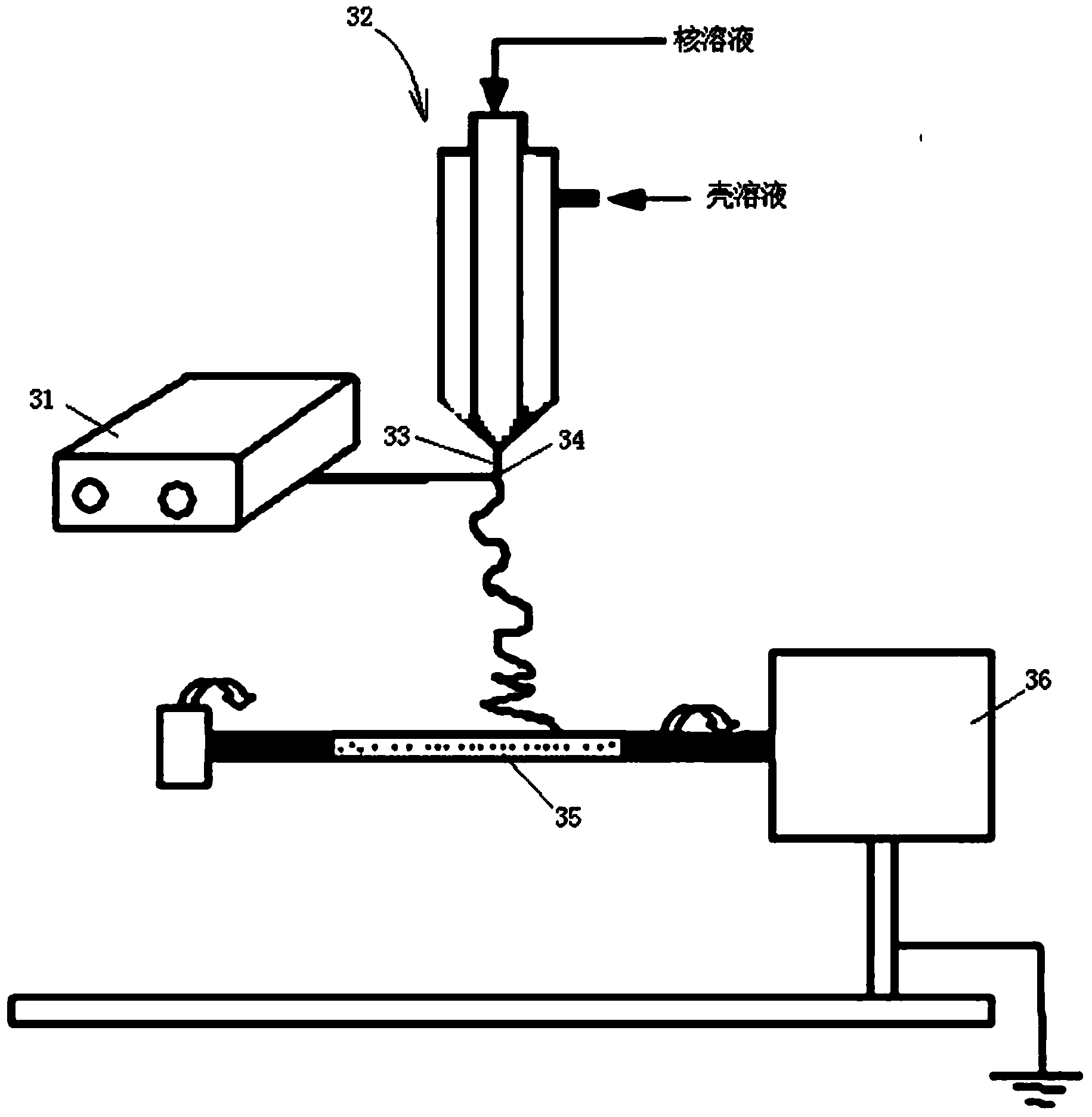

[0030] Add 0.2 g of chitosan to 20 mL of 2% acetic acid, and dissolve 0.2 g of polyvinyl alcohol in 10 mL of distilled water.

[0031] Above-mentioned chitosan solution and polyvinyl alcohol solution are carried out electrospray, electrospray condition is as follows: electrospray voltage 10KV, receiving distance 20cm, internal and external pushing speed ratio 2ml / h:4ml / h, the product that collects after electrospray 1h, Vacuum-dried for 24 hours, weighed and sealed for storage, the fiber diameter was 1520 nanometers.

Embodiment 2

[0033] Add 0.2 g of chitosan to 20 mL of 2% acetic acid, and dissolve 0.2 g of polyvinyl alcohol in 10 mL of distilled water.

[0034] Above-mentioned chitosan solution and polyvinyl alcohol solution are carried out electrospray, electrospray condition is as follows: electrospray voltage 15KV, receiving distance 20cm, internal and external pushing speed ratio 2ml / h:4ml / h, the product that collects after electrospray 1h, Vacuum-dried for 24 hours, weighed and sealed for storage, the fiber diameter was 1040 nanometers.

Embodiment 3

[0036] Add 0.2 g of chitosan to 20 mL of 2% acetic acid, and dissolve 0.2 g of polyvinyl alcohol in 10 mL of distilled water.

[0037] Above-mentioned chitosan solution and polyvinyl alcohol solution are carried out electrospray, electrospray condition is as follows: electrospray voltage 20KV, receiving distance 20cm, internal and external pushing speed ratio 2ml / h:4ml / h, the product that collects after electrospray 1h, Vacuum-dried for 24 hours, weighed and sealed for storage, the fiber diameter was 830 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com